Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, improving fuel efficiency and power output by enabling precise control of the air-fuel mixture. Multi-Point Fuel Injection (MPFI) sprays fuel into the intake manifold near the intake valves, offering smoother operation and better emissions control in comparison to older carburetor systems. GDI systems typically provide superior fuel economy and performance, while MPFI remains favored for its reliability and cost-effectiveness.

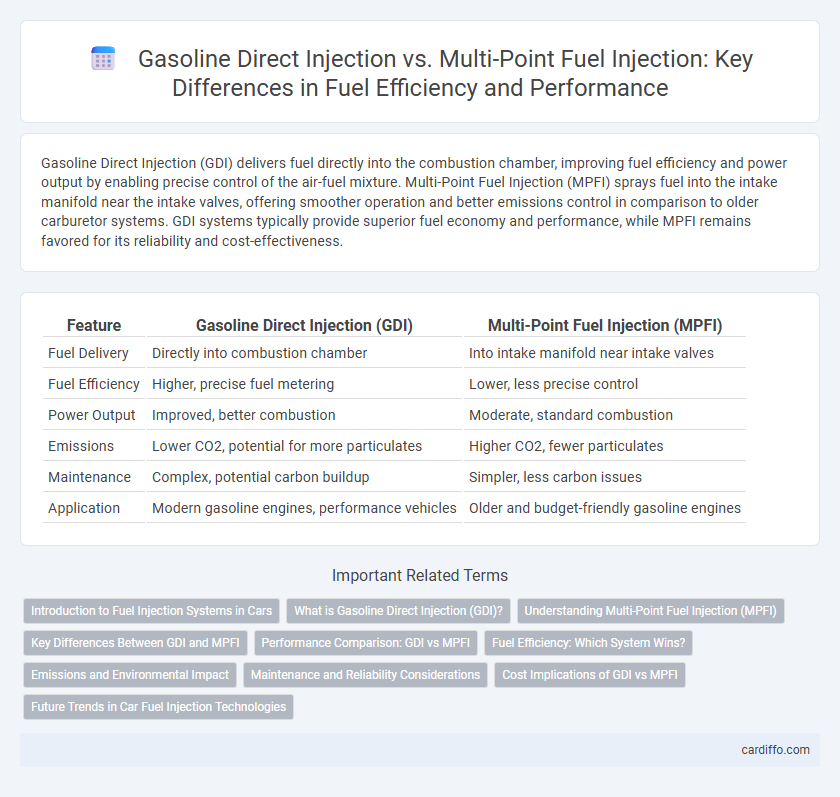

Table of Comparison

| Feature | Gasoline Direct Injection (GDI) | Multi-Point Fuel Injection (MPFI) |

|---|---|---|

| Fuel Delivery | Directly into combustion chamber | Into intake manifold near intake valves |

| Fuel Efficiency | Higher, precise fuel metering | Lower, less precise control |

| Power Output | Improved, better combustion | Moderate, standard combustion |

| Emissions | Lower CO2, potential for more particulates | Higher CO2, fewer particulates |

| Maintenance | Complex, potential carbon buildup | Simpler, less carbon issues |

| Application | Modern gasoline engines, performance vehicles | Older and budget-friendly gasoline engines |

Introduction to Fuel Injection Systems in Cars

Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, improving fuel atomization and combustion efficiency compared to Multi-Point Fuel Injection (MPFI), which sprays fuel into the intake manifold near each cylinder. GDI systems enhance engine performance, fuel economy, and reduce emissions by precisely controlling fuel delivery under varying operating conditions. Multi-Point Fuel Injection remains widely used for its reliability and cost-effectiveness, especially in older and entry-level vehicles.

What is Gasoline Direct Injection (GDI)?

Gasoline Direct Injection (GDI) is an advanced fuel injection system where fuel is injected directly into the combustion chamber of each cylinder at high pressure, enhancing combustion efficiency and power output. Unlike Multi-Point Fuel Injection (MPFI), which delivers fuel into the intake manifold, GDI provides precise fuel metering and improved atomization, resulting in better fuel economy and lower emissions. GDI technology enables higher compression ratios and optimized air-fuel mixtures, contributing to enhanced engine performance and reduced carbon footprint.

Understanding Multi-Point Fuel Injection (MPFI)

Multi-Point Fuel Injection (MPFI) delivers fuel to each cylinder's intake port through individual injectors, ensuring precise fuel atomization and improved combustion efficiency. This system enhances throttle response and reduces emissions compared to older carburetor designs, promoting better fuel economy. MPFI's role in optimizing air-fuel mixture distribution makes it a reliable choice for balanced engine performance in various driving conditions.

Key Differences Between GDI and MPFI

Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, enhancing fuel atomization and combustion efficiency, while Multi-Point Fuel Injection (MPFI) sprays fuel into the intake manifold, providing a more homogeneous air-fuel mixture. GDI systems improve fuel economy and reduce emissions due to precise fuel metering but can be more prone to carbon buildup on intake valves compared to MPFI. MPFI offers simpler maintenance and smoother engine operation at lower costs but generally results in lower fuel efficiency and higher emissions relative to GDI technology.

Performance Comparison: GDI vs MPFI

Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, resulting in enhanced fuel atomization, improved combustion efficiency, and increased power output compared to Multi-Point Fuel Injection (MPFI), which injects fuel into the intake manifold. GDI systems achieve superior throttle response and higher fuel economy while reducing emissions like CO2 and hydrocarbons more effectively than MPFI. Performance metrics consistently show GDI engines provide better torque and horsepower, especially under high-load conditions, making them preferable for modern, performance-oriented vehicles.

Fuel Efficiency: Which System Wins?

Gasoline Direct Injection (GDI) systems enhance fuel efficiency by delivering fuel directly into the combustion chamber, allowing for precise fuel metering and improved combustion control. Multi-Point Fuel Injection (MPFI) disperses fuel into the intake manifold, resulting in less accurate fuel atomization and moderate fuel consumption. GDI engines typically achieve superior miles per gallon (MPG) ratings and reduced emissions compared to MPFI systems due to optimized fuel vaporization and combustion timing.

Emissions and Environmental Impact

Gasoline Direct Injection (GDI) systems offer improved fuel efficiency and lower carbon dioxide (CO2) emissions compared to Multi-Point Fuel Injection (MPFI) by delivering fuel directly into the combustion chamber, resulting in more precise air-fuel mixing and better combustion control. However, GDI engines tend to emit higher levels of particulate matter (PM) and nitrogen oxides (NOx), which contribute to air pollution and pose environmental health risks, necessitating advanced particulate filters and emission control technologies. Multi-Point Fuel Injection, while producing slightly higher CO2 emissions, generally emits fewer fine particles and NOx, making it simpler and potentially less harmful in terms of particulate pollution despite lower fuel economy.

Maintenance and Reliability Considerations

Gasoline Direct Injection (GDI) engines often require more frequent maintenance due to carbon buildup on intake valves, impacting long-term reliability. Multi-Point Fuel Injection (MPFI) systems generally offer easier maintenance and fewer issues with deposits since fuel is sprayed onto the intake valves, providing natural cleaning. Choosing between GDI and MPFI depends on balancing performance benefits with potential maintenance costs and reliability concerns.

Cost Implications of GDI vs MPFI

Gasoline Direct Injection (GDI) systems generally incur higher initial costs compared to Multi-Point Fuel Injection (MPFI) due to advanced components like high-pressure fuel pumps and precise injectors. Maintenance expenses for GDI can also be greater because of carbon buildup on intake valves, requiring periodic cleaning or service. Despite higher upfront and upkeep costs, GDI offers improved fuel efficiency and reduced emissions, which may offset costs through better fuel economy over time.

Future Trends in Car Fuel Injection Technologies

Gasoline Direct Injection (GDI) is rapidly evolving with advancements aimed at improving fuel efficiency and reducing emissions by delivering fuel directly into the combustion chamber at high pressure. Multi-Point Fuel Injection (MPFI) systems remain relevant for their simplicity and cost-effectiveness but face competition from GDI's precision and adaptability in meeting stringent environmental regulations. Future trends emphasize integrating GDI with hybrid and electric powertrains, enhanced sensor technologies, and artificial intelligence to optimize combustion and minimize fuel consumption.

Gasoline Direct Injection vs Multi-Point Fuel Injection Infographic

cardiffo.com

cardiffo.com