Synthetic fuels offer a cleaner alternative to conventional fuels by producing fewer greenhouse gas emissions and reducing dependency on fossil resources. Unlike conventional fuels derived directly from crude oil, synthetic fuels are manufactured through chemical processes using sustainable feedstocks such as biomass, carbon dioxide, and hydrogen. This innovation supports energy diversification and helps mitigate climate change while maintaining compatibility with existing fuel infrastructure.

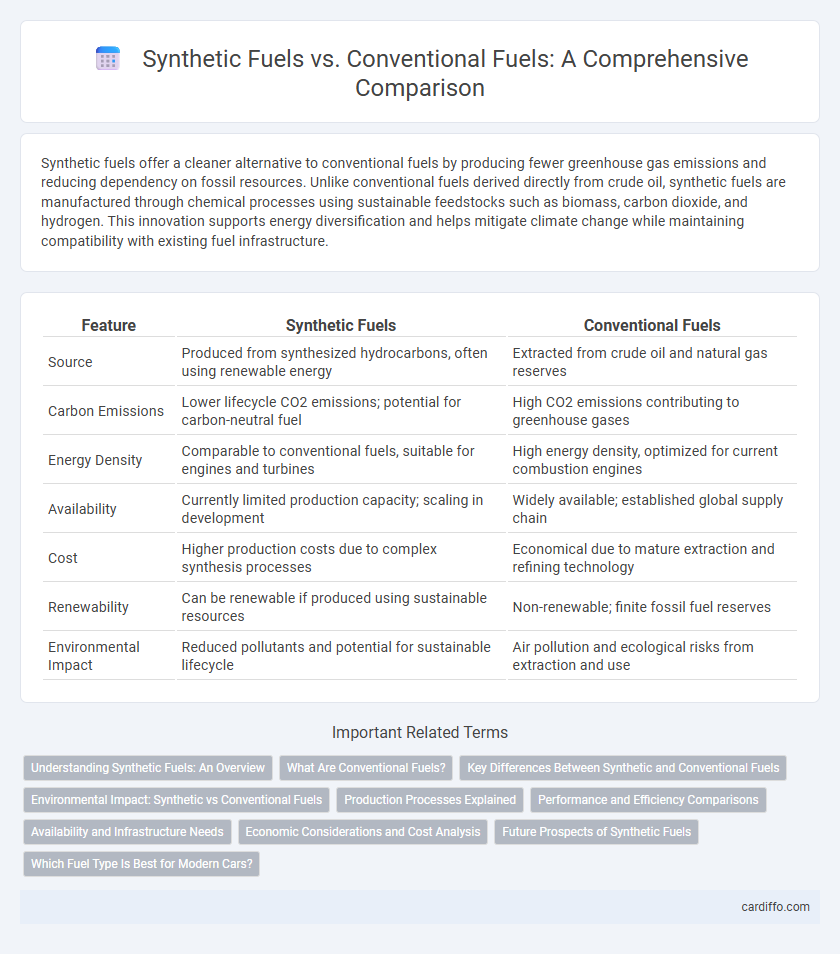

Table of Comparison

| Feature | Synthetic Fuels | Conventional Fuels |

|---|---|---|

| Source | Produced from synthesized hydrocarbons, often using renewable energy | Extracted from crude oil and natural gas reserves |

| Carbon Emissions | Lower lifecycle CO2 emissions; potential for carbon-neutral fuel | High CO2 emissions contributing to greenhouse gases |

| Energy Density | Comparable to conventional fuels, suitable for engines and turbines | High energy density, optimized for current combustion engines |

| Availability | Currently limited production capacity; scaling in development | Widely available; established global supply chain |

| Cost | Higher production costs due to complex synthesis processes | Economical due to mature extraction and refining technology |

| Renewability | Can be renewable if produced using sustainable resources | Non-renewable; finite fossil fuel reserves |

| Environmental Impact | Reduced pollutants and potential for sustainable lifecycle | Air pollution and ecological risks from extraction and use |

Understanding Synthetic Fuels: An Overview

Synthetic fuels, produced through processes like Fischer-Tropsch synthesis or methanol-to-gasoline conversion, offer a cleaner alternative to conventional fossil fuels by utilizing feedstocks such as biomass, natural gas, or captured CO2. These fuels demonstrate potential in reducing greenhouse gas emissions and enhancing energy security by providing liquid fuels compatible with existing infrastructure. Advances in synthetic fuel technologies continue to improve efficiency and cost-effectiveness, making them a promising option for sustainable transportation and industrial applications.

What Are Conventional Fuels?

Conventional fuels primarily consist of petroleum-based products such as gasoline, diesel, and jet fuel, derived from crude oil through refining processes. These fuels are widely used in transportation and industry due to their high energy density and established infrastructure for extraction, distribution, and combustion. Despite their efficiency, conventional fuels release significant greenhouse gas emissions, contributing to environmental pollution and global climate change concerns.

Key Differences Between Synthetic and Conventional Fuels

Synthetic fuels are produced through chemical processes using carbon sources like biomass or carbon dioxide, whereas conventional fuels are derived directly from crude oil refining. Synthetic fuels offer cleaner combustion with lower emissions of sulfur and particulates compared to conventional gasoline and diesel. Energy density and combustion characteristics differ, with synthetic fuels often engineered for optimized performance in modern engines.

Environmental Impact: Synthetic vs Conventional Fuels

Synthetic fuels produce significantly lower greenhouse gas emissions compared to conventional fossil fuels by utilizing captured carbon and renewable energy in their production process. Their lifecycle carbon footprint is reduced due to the recycling of carbon dioxide, minimizing atmospheric pollution and contributing to climate change mitigation. Conventional fuels release high levels of CO2 and pollutants during extraction, refining, and combustion, leading to environmental degradation and air quality issues.

Production Processes Explained

Synthetic fuels are produced through chemical synthesis from feedstocks such as biomass, coal, or natural gas using processes like Fischer-Tropsch or methanol-to-gasoline, enabling the creation of liquid fuels without direct petroleum extraction. Conventional fuels, derived from crude oil through distillation and refining, involve separating and processing hydrocarbons into gasoline, diesel, and other products. The synthetic fuel production process offers greater flexibility in feedstock sources and potential for carbon-neutral output, contrasting with the fossil-dependent, energy-intensive refining of conventional fuels.

Performance and Efficiency Comparisons

Synthetic fuels exhibit higher combustion efficiency and lower pollutant emissions compared to conventional fuels, leading to improved engine performance and reduced environmental impact. Their molecular structure allows for cleaner burning, enhanced energy density, and better thermal stability, resulting in optimized fuel consumption and power output. Conventional fuels often show variability in quality and produce more contaminants, affecting engine longevity and overall efficiency.

Availability and Infrastructure Needs

Synthetic fuels offer greater availability potential by utilizing diverse feedstocks such as biomass, natural gas, and carbon captured from the atmosphere, unlike conventional fuels which rely heavily on finite crude oil reserves. Infrastructure for synthetic fuels can leverage existing fuel distribution and combustion systems with minimal modification, whereas conventional fuels have an established global refining, transport, and retail network optimized over decades. Transitioning to synthetic fuels requires targeted investments in production facilities and carbon capture technologies to build scalable supply chains supporting long-term energy security.

Economic Considerations and Cost Analysis

Synthetic fuels often incur higher production costs due to complex processes such as gasification and catalytic conversion, impacting their market competitiveness against conventional fuels like gasoline and diesel. Conventional fuels benefit from established infrastructure and economies of scale, resulting in lower per-unit costs and more stable prices influenced by global oil markets. However, synthetic fuels offer potential long-term economic advantages through reduced dependence on crude oil imports and price volatility, especially when integrated with renewable energy sources.

Future Prospects of Synthetic Fuels

Synthetic fuels, derived from renewable energy sources and carbon capture technologies, offer a promising alternative to conventional fossil fuels by significantly reducing greenhouse gas emissions. Advancements in production methods such as Power-to-Liquid (PtL) and increased scalability are expected to drive cost competitiveness and widespread adoption in aviation, shipping, and heavy industry sectors. As global policies intensify carbon reduction targets, synthetic fuels hold potential to play a critical role in the decarbonization of hard-to-electrify transportation and energy systems.

Which Fuel Type Is Best for Modern Cars?

Synthetic fuels offer higher efficiency and lower emissions compared to conventional fuels, making them increasingly suitable for modern internal combustion engines designed to meet strict environmental standards. Conventional fuels, derived from crude oil, remain widely available and compatible with existing infrastructure but contribute significantly to greenhouse gas emissions. Advances in synthetic fuel technology provide a cleaner alternative that supports the transition to more sustainable transportation while maintaining engine performance and longevity.

Synthetic Fuels vs Conventional Fuels Infographic

cardiffo.com

cardiffo.com