Direct injection engines produce lower carbon monoxide and hydrocarbon emissions due to precise fuel delivery directly into the combustion chamber, enhancing combustion efficiency. However, they tend to emit more particulate matter compared to port injection engines, which inject fuel into the intake port and offer better air-fuel mixing that reduces particulate emissions. Advances in emission control technologies like gasoline particulate filters are crucial to mitigating the higher particulate output associated with direct injection systems.

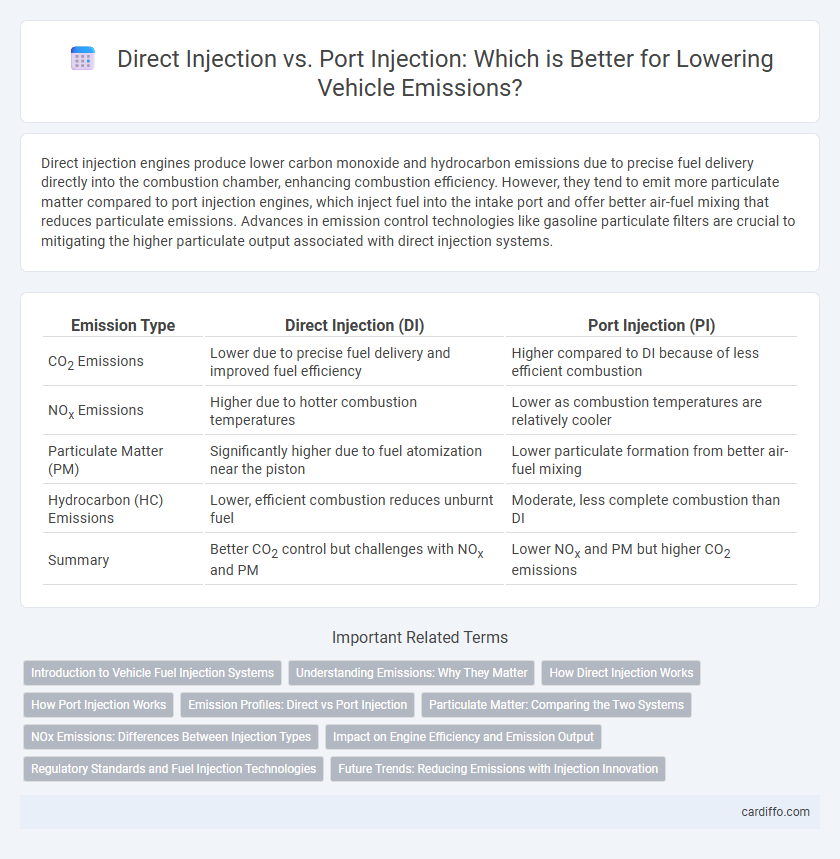

Table of Comparison

| Emission Type | Direct Injection (DI) | Port Injection (PI) |

|---|---|---|

| CO2 Emissions | Lower due to precise fuel delivery and improved fuel efficiency | Higher compared to DI because of less efficient combustion |

| NOx Emissions | Higher due to hotter combustion temperatures | Lower as combustion temperatures are relatively cooler |

| Particulate Matter (PM) | Significantly higher due to fuel atomization near the piston | Lower particulate formation from better air-fuel mixing |

| Hydrocarbon (HC) Emissions | Lower, efficient combustion reduces unburnt fuel | Moderate, less complete combustion than DI |

| Summary | Better CO2 control but challenges with NOx and PM | Lower NOx and PM but higher CO2 emissions |

Introduction to Vehicle Fuel Injection Systems

Direct injection systems spray fuel directly into the combustion chamber, enabling precise control of fuel delivery and improving combustion efficiency, which reduces emissions of unburned hydrocarbons and carbon monoxide. Port injection systems inject fuel into the intake port, allowing better mixing with air before entering the combustion chamber, resulting in lower particulate emissions and reduced engine knock. Understanding the differences in fuel atomization and combustion dynamics between direct and port injection is critical for optimizing vehicle emissions control and meeting stringent environmental standards.

Understanding Emissions: Why They Matter

Direct injection engines produce lower carbon monoxide and hydrocarbon emissions due to precise fuel delivery, improving combustion efficiency. Port injection systems tend to emit fewer particulate matter and nitrogen oxides by enabling better air-fuel mixing and cooler combustion temperatures. Understanding these differences is critical for optimizing vehicle emission control strategies and meeting increasingly strict environmental regulations.

How Direct Injection Works

Direct Injection (DI) injects fuel directly into the combustion chamber at high pressure, allowing for precise timing and improved atomization of fuel. This method enhances combustion efficiency, resulting in reduced unburned hydrocarbons and lower carbon monoxide emissions. DI systems offer better control over the air-fuel mixture, which helps optimize emissions performance compared to port injection.

How Port Injection Works

Port injection works by delivering fuel into the intake manifold just before the intake valve, allowing better air-fuel mixing before combustion. This method reduces particulate emissions and improves fuel atomization, leading to lower unburned hydrocarbons compared to direct injection. By promoting more complete combustion, port injection contributes to cleaner exhaust emissions and enhanced emission control.

Emission Profiles: Direct vs Port Injection

Direct injection engines exhibit lower carbon monoxide (CO) and hydrocarbon (HC) emissions due to precise fuel delivery, yet they tend to produce higher particulate matter (PM) and nitrogen oxides (NOx) compared to port injection systems. Port injection engines generally show reduced particulate emissions and more uniform combustion, resulting in lower PM levels but slightly increased CO and HC output. Emission control technologies such as gasoline particulate filters (GPFs) and advanced catalytic converters are often required to mitigate the higher NOx and PM emissions associated with direct injection systems.

Particulate Matter: Comparing the Two Systems

Direct Injection engines generally produce higher levels of particulate matter (PM) emissions due to the precise fuel spray directly into the combustion chamber, leading to incomplete combustion and soot formation. Port Injection systems inject fuel into the intake manifold, allowing better air-fuel mixing that results in lower particulate emissions and cleaner combustion. Advances in particulate filters and fuel injection technology continue to narrow the emissions gap between Direct Injection and Port Injection systems.

NOx Emissions: Differences Between Injection Types

Direct injection engines produce higher NOx emissions due to elevated combustion temperatures and localized fuel-rich zones promoting nitrogen oxide formation. Port injection systems typically generate lower NOx levels by allowing better air-fuel mixing and cooler combustion temperatures. Regulatory standards increasingly favor port injection or advanced direct injection technologies with exhaust gas recirculation (EGR) to mitigate NOx emissions effectively.

Impact on Engine Efficiency and Emission Output

Direct injection improves engine efficiency by delivering fuel directly into the combustion chamber, promoting better atomization and more precise fuel control, which reduces fuel consumption and lowers CO2 emissions. Port injection, though less efficient at atomizing fuel, tends to produce fewer particulate emissions because fuel mixes with air before entering the cylinder, resulting in cleaner combustion. Balancing the two systems in a dual-injection setup allows optimization of both engine performance and emission output, minimizing NOx and particulate matter simultaneously.

Regulatory Standards and Fuel Injection Technologies

Direct injection (DI) systems deliver fuel directly into the combustion chamber, enabling precise control of fuel-air mixture and combustion timing, which helps reduce CO2 emissions but can increase particulate matter (PM) and NOx levels. Port injection (PI) injects fuel into the intake manifold, promoting better fuel-air mixing and typically lower particulate emissions, but with less efficiency in controlling combustion, often resulting in higher CO2 emissions compared to DI. Regulatory standards such as Euro 6 and Tier 3 enforce strict limits on NOx and PM, prompting manufacturers to adopt advanced emission control technologies like particulate filters and selective catalytic reduction systems to comply while balancing the benefits and drawbacks of both injection methods.

Future Trends: Reducing Emissions with Injection Innovation

Direct injection systems improve fuel atomization and combustion efficiency, significantly lowering CO2 emissions compared to traditional port injection. Future trends emphasize combining direct injection with advanced particulate filters and optimized injection timing to minimize particulate matter and NOx emissions. Innovations such as dual-injection strategies and electrified fuel delivery promise further emission reductions aligned with stricter environmental regulations.

Direct Injection vs Port Injection (Emissions context) Infographic

cardiffo.com

cardiffo.com