Particulate filter regeneration is a process that removes accumulated soot from diesel particulate filters by raising the exhaust temperature to burn off particles, thus reducing particulate matter emissions. Selective Catalytic Reduction (SCR) uses a urea-based additive injected into the exhaust stream to chemically convert nitrogen oxides (NOx) into harmless nitrogen and water, significantly lowering NOx emissions. Both technologies complement each other by targeting different pollutants to meet stringent emission standards effectively.

Table of Comparison

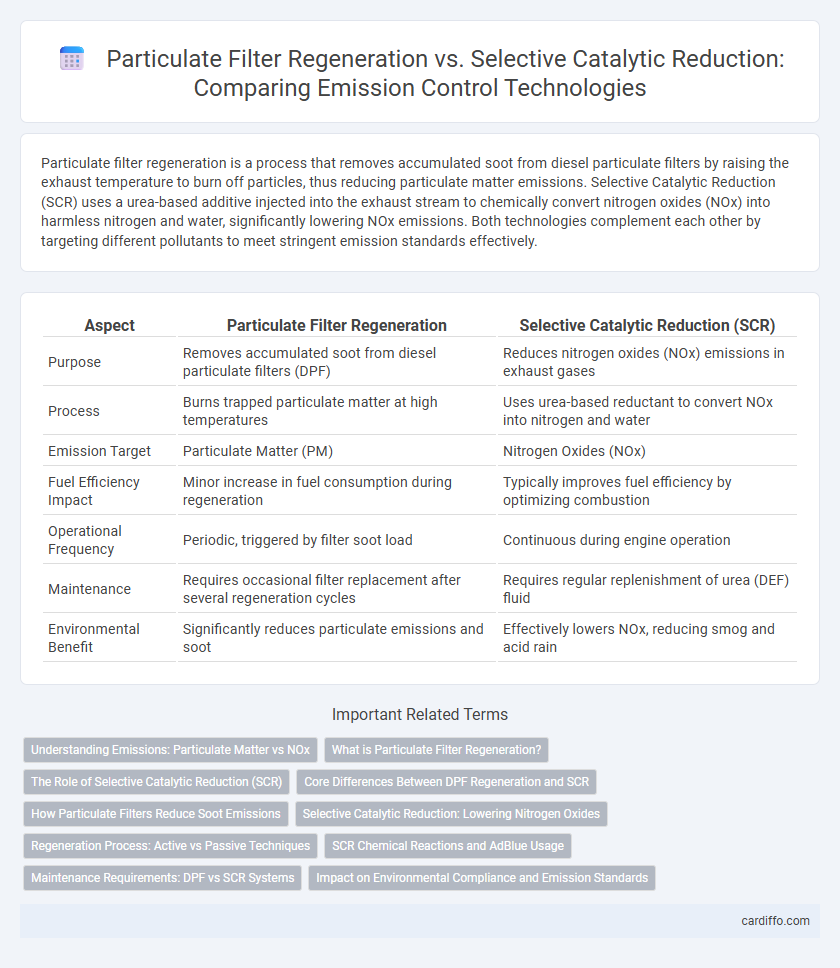

| Aspect | Particulate Filter Regeneration | Selective Catalytic Reduction (SCR) |

|---|---|---|

| Purpose | Removes accumulated soot from diesel particulate filters (DPF) | Reduces nitrogen oxides (NOx) emissions in exhaust gases |

| Process | Burns trapped particulate matter at high temperatures | Uses urea-based reductant to convert NOx into nitrogen and water |

| Emission Target | Particulate Matter (PM) | Nitrogen Oxides (NOx) |

| Fuel Efficiency Impact | Minor increase in fuel consumption during regeneration | Typically improves fuel efficiency by optimizing combustion |

| Operational Frequency | Periodic, triggered by filter soot load | Continuous during engine operation |

| Maintenance | Requires occasional filter replacement after several regeneration cycles | Requires regular replenishment of urea (DEF) fluid |

| Environmental Benefit | Significantly reduces particulate emissions and soot | Effectively lowers NOx, reducing smog and acid rain |

Understanding Emissions: Particulate Matter vs NOx

Particulate filter regeneration targets the reduction of particulate matter (PM) emissions by oxidizing accumulated soot in diesel particulate filters, effectively minimizing harmful solid particles released into the atmosphere. Selective Catalytic Reduction (SCR) primarily reduces nitrogen oxides (NOx) emissions through the injection of a urea-based solution, converting NOx into harmless nitrogen and water vapor. Understanding these distinct emission control technologies highlights their complementary roles in achieving comprehensive pollution reduction and meeting stringent environmental regulations.

What is Particulate Filter Regeneration?

Particulate Filter Regeneration is a process that removes accumulated soot from a diesel particulate filter (DPF) by increasing exhaust temperatures to oxidize trapped particles into carbon dioxide. This method is essential for maintaining the filter's efficiency, reducing harmful particulate matter emissions, and preventing device clogging. Unlike Selective Catalytic Reduction, which targets nitrogen oxides (NOx), particulate filter regeneration specifically addresses solid particle pollution in diesel exhaust.

The Role of Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction (SCR) plays a critical role in reducing nitrogen oxide (NOx) emissions from diesel engines by converting harmful NOx gases into nitrogen and water through a chemical reaction with a urea-based additive. Unlike particulate filter regeneration, which targets soot and particulate matter, SCR specifically addresses gaseous pollutants, enhancing overall emission control. This technology significantly improves air quality by meeting stringent emission standards and increasing fuel efficiency in modern diesel vehicles.

Core Differences Between DPF Regeneration and SCR

Diesel Particulate Filter (DPF) regeneration primarily targets the removal of accumulated soot particles through controlled combustion, reducing particulate matter emissions from diesel engines. Selective Catalytic Reduction (SCR) focuses on converting nitrogen oxides (NOx) into nitrogen and water by injecting a urea-based solution into the exhaust stream, addressing gaseous pollutant reduction. Core differences lie in their pollutant targets--DPF manages solid particulates while SCR treats gaseous NOx emissions--and their operational mechanisms, with DPF regeneration relying on temperature elevation for soot oxidation, and SCR employing a chemical catalyst for NOx conversion.

How Particulate Filters Reduce Soot Emissions

Particulate filters reduce soot emissions by trapping and storing fine particulate matter from diesel exhaust gases, preventing their release into the atmosphere. Through a process called regeneration, accumulated soot is oxidized at high temperatures, converting it into less harmful substances like carbon dioxide. This method effectively decreases particulate pollution, complementing Selective Catalytic Reduction systems that primarily target nitrogen oxides.

Selective Catalytic Reduction: Lowering Nitrogen Oxides

Selective Catalytic Reduction (SCR) is a cutting-edge emission control technology designed to significantly reduce nitrogen oxides (NOx) from diesel engine exhaust by converting them into harmless nitrogen and water using a urea-based reductant. Unlike particulate filter regeneration, which primarily targets soot and particulate matter, SCR focuses on lowering NOx emissions, a major contributor to smog and acid rain. Advanced SCR systems optimize catalyst efficiency and reductant dosing, enabling compliance with stringent emission standards such as Euro 6 and EPA Tier 4.

Regeneration Process: Active vs Passive Techniques

Particulate filter regeneration in diesel engines involves two primary methods: active and passive regeneration. Passive regeneration occurs during normal engine operation when exhaust temperatures are sufficiently high to oxidize accumulated soot without external intervention. Active regeneration is triggered by the engine control unit, increasing exhaust temperature through fuel injection strategies to burn off soot when passive conditions are insufficient, ensuring optimal particulate filter efficiency and reduced emissions.

SCR Chemical Reactions and AdBlue Usage

Selective Catalytic Reduction (SCR) uses AdBlue, a urea-based solution, to convert nitrogen oxides (NOx) into harmless nitrogen and water through chemical reactions occurring on a catalyst surface. Unlike particulate filter regeneration, which burns off accumulated soot at high temperatures, SCR chemically reduces NOx emissions by injecting AdBlue into the exhaust stream, where it decomposes into ammonia and reacts with NOx to form nitrogen and water. This process significantly lowers NOx emissions, helping diesel engines meet stringent emission standards without increasing particulate matter levels.

Maintenance Requirements: DPF vs SCR Systems

Diesel Particulate Filters (DPF) require periodic regeneration to burn off accumulated soot, often triggered automatically by the engine control unit but sometimes needing manual intervention or specific driving conditions to complete the cycle. Selective Catalytic Reduction (SCR) systems demand continuous dosing of Diesel Exhaust Fluid (DEF) and regular refills, along with maintenance of NOx sensors and catalyst components to ensure optimal function. Compared to DPFs, SCR maintenance emphasizes fluid management and sensor reliability, while DPF systems focus more on periodic ash removal and filter integrity checks to maintain emission standards.

Impact on Environmental Compliance and Emission Standards

Particulate Filter Regeneration effectively reduces particulate matter emissions by trapping and burning soot within diesel particulate filters, ensuring compliance with strict particulate emission standards like Euro 6. Selective Catalytic Reduction (SCR) targets nitrogen oxides (NOx) by converting them into nitrogen and water through a chemical reaction with urea-based AdBlue, significantly lowering NOx emissions to meet stringent regulations such as EPA Tier 4 and Euro 6d. Combining both technologies enables vehicles to comply with comprehensive emission standards by addressing multiple pollutants simultaneously, enhancing environmental performance and regulatory adherence.

Particulate Filter Regeneration vs Selective Catalytic Reduction Infographic

cardiffo.com

cardiffo.com