Catalytic converters reduce harmful emissions by converting toxic gases like carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances such as carbon dioxide and nitrogen. Diesel particulate filters specifically target and trap soot particles from diesel exhaust, significantly decreasing particulate matter emissions and improving air quality. Both technologies play essential roles in meeting stringent emission standards and reducing environmental impact from vehicles.

Table of Comparison

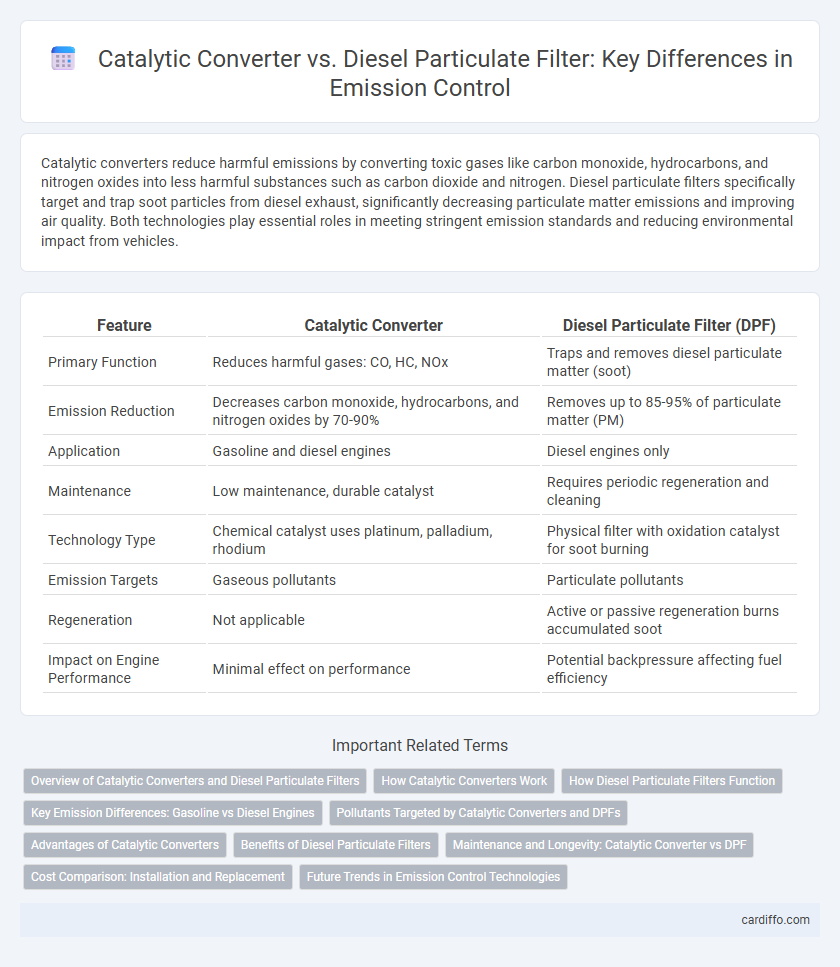

| Feature | Catalytic Converter | Diesel Particulate Filter (DPF) |

|---|---|---|

| Primary Function | Reduces harmful gases: CO, HC, NOx | Traps and removes diesel particulate matter (soot) |

| Emission Reduction | Decreases carbon monoxide, hydrocarbons, and nitrogen oxides by 70-90% | Removes up to 85-95% of particulate matter (PM) |

| Application | Gasoline and diesel engines | Diesel engines only |

| Maintenance | Low maintenance, durable catalyst | Requires periodic regeneration and cleaning |

| Technology Type | Chemical catalyst uses platinum, palladium, rhodium | Physical filter with oxidation catalyst for soot burning |

| Emission Targets | Gaseous pollutants | Particulate pollutants |

| Regeneration | Not applicable | Active or passive regeneration burns accumulated soot |

| Impact on Engine Performance | Minimal effect on performance | Potential backpressure affecting fuel efficiency |

Overview of Catalytic Converters and Diesel Particulate Filters

Catalytic converters reduce harmful exhaust gases like carbon monoxide, hydrocarbons, and nitrogen oxides by facilitating chemical reactions that convert them into less toxic substances, primarily carbon dioxide and nitrogen. Diesel particulate filters (DPFs) specifically target fine particulate matter, trapping soot and ash from diesel engine exhaust to prevent harmful emissions from entering the atmosphere. Both devices play crucial roles in vehicle emission control systems by addressing different pollutant types to meet stringent environmental regulations.

How Catalytic Converters Work

Catalytic converters reduce harmful vehicle emissions by converting toxic gases such as carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances like carbon dioxide, water vapor, and nitrogen through redox reactions. These devices contain a ceramic or metallic honeycomb structure coated with precious metals such as platinum, palladium, and rhodium that act as catalysts to accelerate chemical reactions without being consumed. By facilitating oxidation and reduction processes, catalytic converters play a crucial role in meeting stringent emission standards and improving air quality.

How Diesel Particulate Filters Function

Diesel Particulate Filters (DPFs) trap and remove soot particles from diesel engine exhaust by filtering out particulate matter through a porous ceramic substrate. During regeneration, accumulated particulates are burned off at high temperatures, converting them into harmless gases like carbon dioxide, thus preventing harmful emissions from entering the atmosphere. Unlike catalytic converters, which primarily target gaseous pollutants, DPFs specifically reduce solid particle emissions, significantly improving air quality and meeting stringent emission standards.

Key Emission Differences: Gasoline vs Diesel Engines

Catalytic converters primarily reduce harmful gases like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) from gasoline engines, while diesel particulate filters (DPFs) target the removal of fine particulate matter (PM) and soot emissions unique to diesel engines. Gasoline engines emit lower particulate matter but higher volatile organic compounds (VOCs), whereas diesel engines produce significantly more PM and NOx, necessitating specialized filtration with DPF technology. Emission regulations for diesel engines emphasize particulate and NOx control, with DPFs playing a critical role in meeting stringent environmental standards.

Pollutants Targeted by Catalytic Converters and DPFs

Catalytic converters primarily target carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) by converting them into less harmful gases like carbon dioxide (CO2), nitrogen (N2), and water vapor (H2O). Diesel particulate filters (DPFs) specialize in capturing and removing particulate matter (PM) or soot from diesel exhaust, significantly reducing fine particles that contribute to air pollution and respiratory problems. While catalytic converters focus on gases, DPFs are essential for controlling solid pollutant emissions specific to diesel engines.

Advantages of Catalytic Converters

Catalytic converters efficiently reduce harmful emissions by converting carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic gases such as carbon dioxide and nitrogen. They require less maintenance compared to diesel particulate filters and are effective across a wide range of engine types, including gasoline and diesel engines. Their ability to promote cleaner exhaust gases significantly contributes to improved air quality and compliance with stringent emission regulations.

Benefits of Diesel Particulate Filters

Diesel Particulate Filters (DPFs) significantly reduce harmful particulate matter emissions from diesel engines by capturing and oxidizing soot particles, improving air quality and public health outcomes. Unlike catalytic converters, which primarily target gaseous pollutants such as carbon monoxide and nitrogen oxides, DPFs directly target ultrafine particulate emissions responsible for respiratory issues and environmental pollution. Implementation of DPF technology aligns with stringent emission standards like Euro 6 and EPA regulations, making it essential for modern diesel engine compliance and sustainability efforts.

Maintenance and Longevity: Catalytic Converter vs DPF

Catalytic converters typically require less frequent maintenance and can last over 100,000 miles, while diesel particulate filters (DPF) demand regular cleaning or regeneration to prevent clogging and maintain efficiency. Failure to properly maintain a DPF can lead to increased backpressure, reduced fuel economy, and costly replacements, often occurring between 80,000 to 120,000 miles. Both components are critical for reducing harmful emissions, but the DPF's sensitivity to soot buildup necessitates more diligent upkeep for optimal longevity.

Cost Comparison: Installation and Replacement

Catalytic converters typically cost between $945 and $1,500 for installation and replacement, while diesel particulate filters (DPFs) range from $1,500 to $4,000, making DPFs significantly more expensive due to their complex design and regeneration technology. Labor costs for both systems vary by vehicle make and model, but DPFs generally require more frequent maintenance and specialized servicing, increasing overall expenses. Investing in a catalytic converter offers a lower upfront cost, whereas DPFs incur higher installation and replacement costs aligned with stricter diesel emission standards.

Future Trends in Emission Control Technologies

Future trends in emission control technologies emphasize the integration of advanced catalytic converters with diesel particulate filters (DPFs) to achieve ultra-low emissions in both gasoline and diesel engines. Innovations in catalyst formulations and DPF materials aim to enhance pollutant conversion efficiency while reducing backpressure and fuel consumption. Emerging hybrid systems combining selective catalytic reduction (SCR) with DPFs are projected to meet increasingly stringent global emission standards.

Catalytic Converter vs Diesel Particulate Filter Infographic

cardiffo.com

cardiffo.com