Oxidative catalysts primarily target carbon monoxide (CO) and hydrocarbons (HC) by promoting their oxidation into carbon dioxide (CO2) and water, effectively reducing harmful emissions from petrol engines. Three-way catalysts combine oxidation and reduction reactions, simultaneously converting CO, HC, and nitrogen oxides (NOx) into less harmful substances, making them essential for meeting stringent emission standards. The advanced design of three-way catalysts allows for better control of multiple pollutants, increasing overall engine efficiency and environmental compliance.

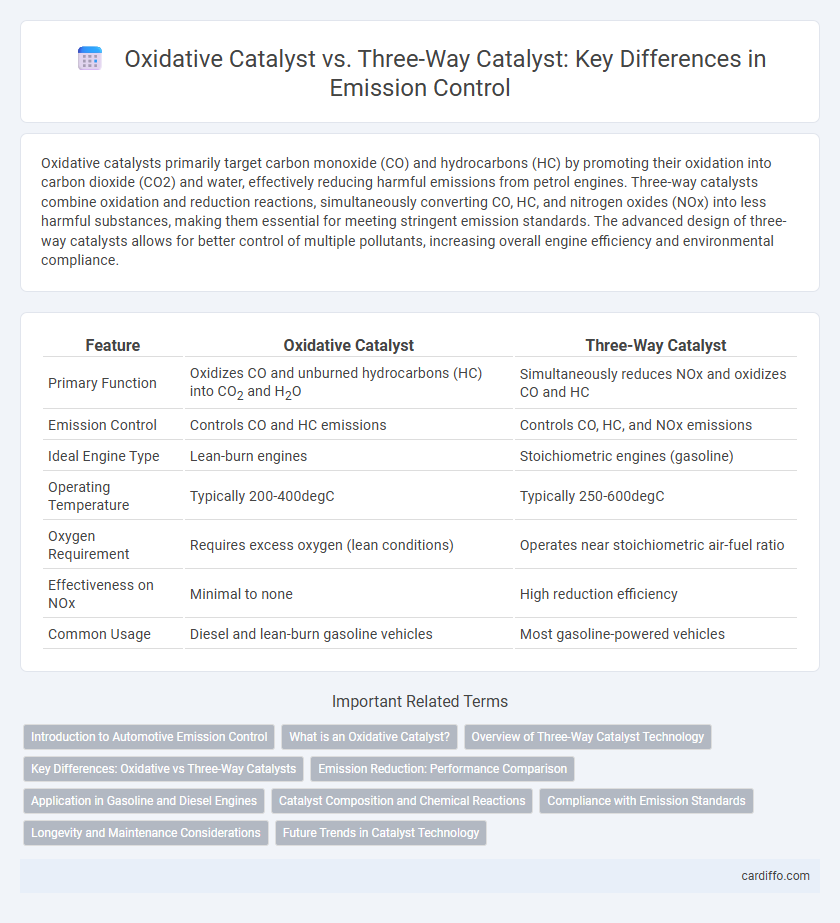

Table of Comparison

| Feature | Oxidative Catalyst | Three-Way Catalyst |

|---|---|---|

| Primary Function | Oxidizes CO and unburned hydrocarbons (HC) into CO2 and H2O | Simultaneously reduces NOx and oxidizes CO and HC |

| Emission Control | Controls CO and HC emissions | Controls CO, HC, and NOx emissions |

| Ideal Engine Type | Lean-burn engines | Stoichiometric engines (gasoline) |

| Operating Temperature | Typically 200-400degC | Typically 250-600degC |

| Oxygen Requirement | Requires excess oxygen (lean conditions) | Operates near stoichiometric air-fuel ratio |

| Effectiveness on NOx | Minimal to none | High reduction efficiency |

| Common Usage | Diesel and lean-burn gasoline vehicles | Most gasoline-powered vehicles |

Introduction to Automotive Emission Control

Oxidative catalysts primarily reduce hydrocarbon (HC) and carbon monoxide (CO) emissions by promoting their oxidation into carbon dioxide (CO2) and water (H2O). Three-way catalysts (TWCs) simultaneously control HC, CO, and nitrogen oxides (NOx) by facilitating oxidation and reduction reactions under stoichiometric air-fuel conditions. TWCs are essential in modern gasoline engines for comprehensive emission control and compliance with stringent environmental regulations.

What is an Oxidative Catalyst?

An oxidative catalyst is a device used in vehicle exhaust systems to convert harmful carbon monoxide (CO) and unburned hydrocarbons (HC) into less harmful carbon dioxide (CO2) and water vapor (H2O) through oxidation reactions. Unlike three-way catalysts that simultaneously reduce nitrogen oxides (NOx), oxidative catalysts focus solely on oxidation processes, making them essential in diesel engines and older gasoline engines with lean burn conditions. These catalysts typically use precious metals like platinum and palladium to enhance the oxidation efficiency and reduce tailpipe emissions.

Overview of Three-Way Catalyst Technology

Three-way catalyst technology simultaneously reduces nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC) by facilitating oxidation and reduction reactions within the exhaust stream. Unlike oxidative catalysts that primarily oxidize CO and HC, three-way catalysts use a ceramic or metallic substrate coated with precious metals like platinum, palladium, and rhodium to achieve all three reactions under stoichiometric combustion conditions. This integrated approach significantly enhances emission control efficiency in gasoline engines, making it the standard technology for meeting stringent emissions regulations worldwide.

Key Differences: Oxidative vs Three-Way Catalysts

Oxidative catalysts primarily reduce carbon monoxide (CO) and hydrocarbons (HC) by converting them into carbon dioxide (CO2) and water, operating effectively in oxygen-rich environments. Three-way catalysts simultaneously reduce nitrogen oxides (NOx) while oxidizing CO and HC, requiring precise control of the air-fuel ratio for optimal performance. The key difference lies in their functionality: oxidative catalysts target only oxidation reactions, whereas three-way catalysts manage both oxidation and reduction processes to address a broader range of emissions.

Emission Reduction: Performance Comparison

Oxidative catalysts primarily reduce carbon monoxide (CO) and hydrocarbons (HC) emissions by converting them into carbon dioxide (CO2) and water, making them effective for lean-burn engines but less efficient at nitrogen oxides (NOx) removal. Three-way catalysts (TWCs) simultaneously reduce CO, HC, and NOx emissions through oxidation and reduction reactions, which enhances overall emission control performance, especially under stoichiometric combustion conditions. The superior emission reduction capability of TWCs makes them the preferred choice in gasoline engines to meet stringent environmental regulations.

Application in Gasoline and Diesel Engines

Oxidative catalysts are primarily used in diesel engines to reduce carbon monoxide and hydrocarbons by promoting oxidation reactions, while three-way catalysts are essential in gasoline engines for simultaneously controlling carbon monoxide, hydrocarbons, and nitrogen oxides through oxidation and reduction reactions. Diesel engines benefit from oxidative catalysts due to their lean burn operation, which produces higher oxygen levels, whereas gasoline engines require three-way catalysts to manage stoichiometric air-fuel ratios effectively. The distinct catalytic properties enable optimized emission control tailored to the differing combustion and exhaust conditions of gasoline and diesel powertrains.

Catalyst Composition and Chemical Reactions

Oxidative catalysts primarily consist of noble metals such as platinum and palladium that promote the oxidation of carbon monoxide (CO) and hydrocarbons (HC) into carbon dioxide (CO2) and water (H2O). In contrast, three-way catalysts contain a combination of platinum, palladium, and rhodium, enabling simultaneous oxidation of CO and HC along with the reduction of nitrogen oxides (NOx) into nitrogen (N2) and oxygen (O2). The distinct catalyst composition and chemical reactions allow three-way catalysts to manage a broader range of emissions in stoichiometric combustion engines.

Compliance with Emission Standards

Oxidative catalysts primarily reduce carbon monoxide (CO) and hydrocarbons (HC) by converting them into carbon dioxide (CO2) and water but are less effective in controlling nitrogen oxides (NOx), limiting their compliance with stringent emission standards like Euro 6 and Tier 3. Three-way catalysts simultaneously reduce CO, HC, and NOx through redox reactions, enabling full compliance with modern emission regulations for gasoline engines. Regulatory bodies favor three-way catalysts for their ability to meet low emission limits, ensuring better environmental and health outcomes.

Longevity and Maintenance Considerations

Oxidative catalysts generally exhibit longer operational life due to their simpler design and less susceptibility to contamination, reducing the frequency of maintenance interventions. Three-way catalysts require precise control of air-fuel mixture and periodic inspections to maintain efficiency, as their complex function managing CO, HC, and NOx emissions increases vulnerability to degradation over time. Regular monitoring and timely replacement of three-way catalysts are essential for sustained emission control performance, especially in vehicles with advanced engine management systems.

Future Trends in Catalyst Technology

Future trends in emission control highlight advancements in oxidative catalyst materials that enhance selective oxidation of pollutants, improving efficiency under lean-burn engine conditions. Three-way catalysts continue to evolve with innovations in precious metal loading reduction and integration of advanced sensor feedback for real-time emission optimization. Research prioritizes durability improvements and cost-effective manufacturing techniques to meet stringent global regulations and future electric-hybrid powertrain applications.

Oxidative catalyst vs Three-way catalyst Infographic

cardiffo.com

cardiffo.com