Particulate filters capture soot and fine particles from diesel exhaust, significantly reducing airborne black carbon emissions, while catalytic converters chemically transform harmful gases like carbon monoxide, nitrogen oxides, and hydrocarbons into less toxic substances such as carbon dioxide and water vapor. Both technologies play crucial roles in lowering vehicle emissions, with particulate filters primarily targeting solid pollutants and catalytic converters focusing on gaseous contaminants. Integrating these systems ensures comprehensive emission control, improving air quality and complying with stringent environmental regulations.

Table of Comparison

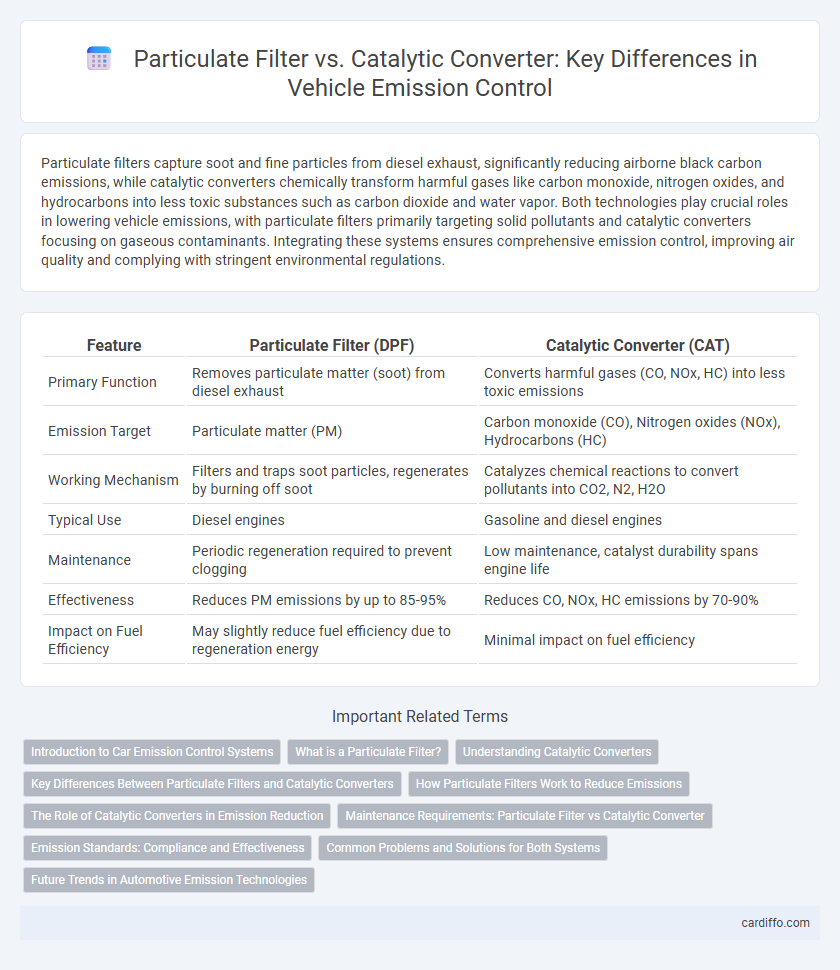

| Feature | Particulate Filter (DPF) | Catalytic Converter (CAT) |

|---|---|---|

| Primary Function | Removes particulate matter (soot) from diesel exhaust | Converts harmful gases (CO, NOx, HC) into less toxic emissions |

| Emission Target | Particulate matter (PM) | Carbon monoxide (CO), Nitrogen oxides (NOx), Hydrocarbons (HC) |

| Working Mechanism | Filters and traps soot particles, regenerates by burning off soot | Catalyzes chemical reactions to convert pollutants into CO2, N2, H2O |

| Typical Use | Diesel engines | Gasoline and diesel engines |

| Maintenance | Periodic regeneration required to prevent clogging | Low maintenance, catalyst durability spans engine life |

| Effectiveness | Reduces PM emissions by up to 85-95% | Reduces CO, NOx, HC emissions by 70-90% |

| Impact on Fuel Efficiency | May slightly reduce fuel efficiency due to regeneration energy | Minimal impact on fuel efficiency |

Introduction to Car Emission Control Systems

Particulate filters capture and reduce soot particles from diesel engines, significantly lowering harmful particulate emissions. Catalytic converters chemically convert toxic gases like carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances such as carbon dioxide and nitrogen. These emission control systems are essential for meeting stringent environmental regulations and improving air quality in urban areas.

What is a Particulate Filter?

A particulate filter is an advanced emission control device designed to capture and remove fine particulate matter (PM) from exhaust gases, primarily in diesel engines. It traps soot and other solid pollutants through a porous ceramic or metallic honeycomb structure, reducing harmful emissions and improving air quality. Unlike catalytic converters that primarily target gaseous pollutants, particulate filters focus on eliminating solid particles, significantly lowering overall engine pollution.

Understanding Catalytic Converters

Catalytic converters transform harmful exhaust gases like carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic substances such as carbon dioxide, nitrogen, and water vapor through oxidation and reduction reactions. These devices contain precious metals like platinum, palladium, and rhodium that act as catalysts to accelerate chemical reactions without being consumed. Unlike particulate filters, which trap solid particles, catalytic converters primarily target gaseous pollutants to reduce vehicle emissions efficiently.

Key Differences Between Particulate Filters and Catalytic Converters

Particulate filters primarily capture and remove solid particles from diesel exhaust, significantly reducing soot emissions. Catalytic converters facilitate chemical reactions to convert harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances such as carbon dioxide and nitrogen. Unlike particulate filters, which target particulate matter, catalytic converters focus on gaseous pollutants, making each device essential for comprehensive emission control in modern vehicles.

How Particulate Filters Work to Reduce Emissions

Particulate filters reduce emissions by capturing and storing soot particles from diesel exhaust, preventing them from entering the atmosphere. These filters use a porous ceramic or metallic substrate that traps particulate matter, which is later burned off during regeneration cycles to clean the filter. This process significantly lowers harmful black carbon emissions, improving air quality and meeting stringent environmental regulations.

The Role of Catalytic Converters in Emission Reduction

Catalytic converters play a critical role in emission reduction by converting harmful pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful gases like carbon dioxide, nitrogen, and water vapor through chemical reactions facilitated by precious metals like platinum, palladium, and rhodium. Unlike particulate filters that trap solid particles and soot, catalytic converters target gaseous emissions, significantly lowering smog-causing substances and improving air quality. Their efficiency in reducing toxic gases makes them indispensable components in modern vehicles to meet stringent emissions regulations worldwide.

Maintenance Requirements: Particulate Filter vs Catalytic Converter

Particulate filters require regular regeneration or cleaning to prevent clogging from trapped soot particles, ensuring optimal performance and longevity. Catalytic converters demand less frequent maintenance but must be protected from contamination by oil or antifreeze, which can impair their ability to convert harmful emissions. Proper upkeep of both components is essential for maintaining emissions control and vehicle efficiency.

Emission Standards: Compliance and Effectiveness

Particulate filters and catalytic converters play crucial roles in meeting emission standards by targeting different pollutants; particulate filters effectively reduce soot and fine particles from diesel engines, while catalytic converters primarily convert harmful gases like carbon monoxide, nitrogen oxides, and hydrocarbons into less toxic emissions. Compliance with strict regulations such as Euro 6 and Tier 3 relies on the combined use of both technologies to ensure comprehensive emission reduction. Studies show that integrating particulate filters with advanced catalytic converters significantly enhances overall emission control, ensuring vehicles meet or exceed current environmental standards.

Common Problems and Solutions for Both Systems

Particulate filters often face clogging from soot accumulation, requiring regular regeneration processes or manual cleaning to restore efficiency, while catalytic converters typically suffer from poisoning due to contaminants like lead or sulfur, which can be mitigated by using high-quality fuel and timely catalyst replacement. Both systems are prone to damage from thermal stress, necessitating monitoring exhaust temperatures and ensuring proper engine tuning to prevent overheating. Implementing routine inspections and maintaining optimal combustion conditions are effective solutions to maximize the lifespan and performance of particulate filters and catalytic converters.

Future Trends in Automotive Emission Technologies

Particulate filters and catalytic converters are evolving to meet stringent future emission standards, with particulate filters becoming more advanced to capture ultrafine particles in gasoline and diesel engines. Innovations in catalytic converter materials, such as the use of rare-earth metals and improved catalyst formulations, aim to enhance conversion efficiency and reduce precious metal dependency. Emerging hybrid systems integrate both technologies with real-time monitoring and adaptive controls, enabling vehicles to achieve lower emissions and comply with upcoming Euro 7 and global environmental regulations.

Particulate Filter vs Catalytic Converter Infographic

cardiffo.com

cardiffo.com