OBD-II emission testing monitors a vehicle's onboard diagnostics system to detect emission-related malfunctions in real time, providing a quicker and more accurate assessment of pollutant levels. IM240 emission testing involves a dynamometer test that measures tailpipe emissions during a simulated driving cycle, offering a detailed evaluation of a vehicle's exhaust gases under various operating conditions. OBD-II testing is generally favored for its efficiency and ability to identify specific emission control system failures, while IM240 remains valuable for comprehensive emissions analysis in older or non-OBD-II compliant vehicles.

Table of Comparison

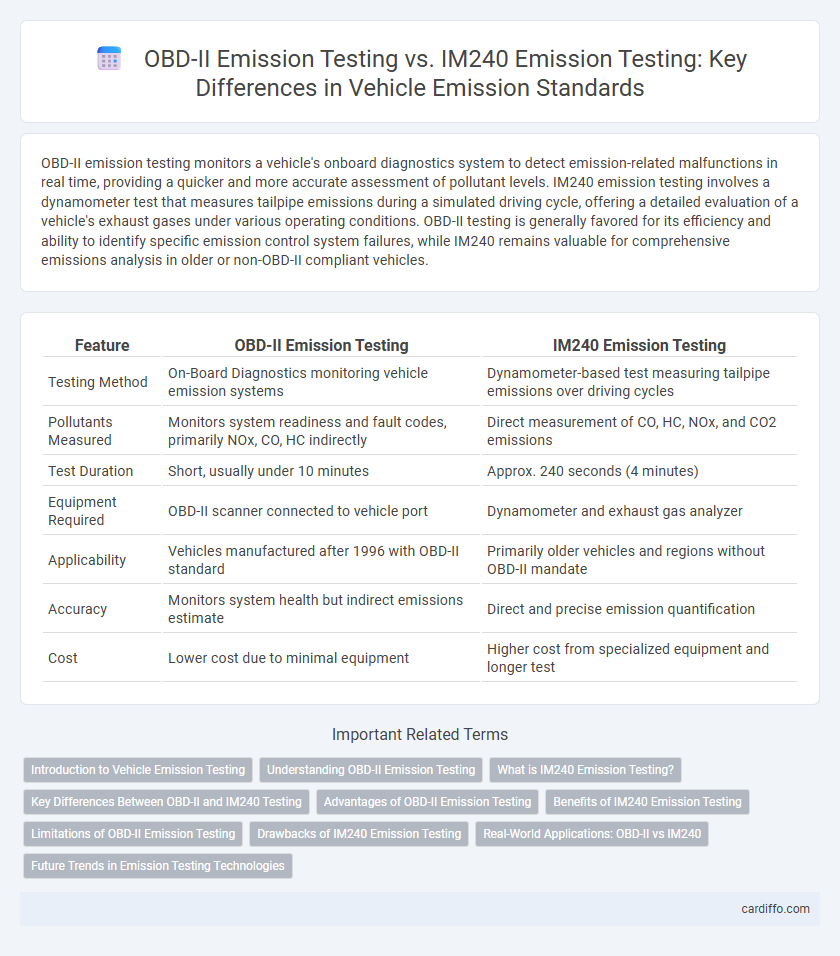

| Feature | OBD-II Emission Testing | IM240 Emission Testing |

|---|---|---|

| Testing Method | On-Board Diagnostics monitoring vehicle emission systems | Dynamometer-based test measuring tailpipe emissions over driving cycles |

| Pollutants Measured | Monitors system readiness and fault codes, primarily NOx, CO, HC indirectly | Direct measurement of CO, HC, NOx, and CO2 emissions |

| Test Duration | Short, usually under 10 minutes | Approx. 240 seconds (4 minutes) |

| Equipment Required | OBD-II scanner connected to vehicle port | Dynamometer and exhaust gas analyzer |

| Applicability | Vehicles manufactured after 1996 with OBD-II standard | Primarily older vehicles and regions without OBD-II mandate |

| Accuracy | Monitors system health but indirect emissions estimate | Direct and precise emission quantification |

| Cost | Lower cost due to minimal equipment | Higher cost from specialized equipment and longer test |

Introduction to Vehicle Emission Testing

OBD-II emission testing monitors a vehicle's onboard diagnostic system to detect emission control malfunctions that impact pollutants like CO, NOx, and hydrocarbons, ensuring compliance with environmental standards. IM240 emission testing measures actual tailpipe emissions over a 240-second driving cycle, capturing real-world pollutant output during acceleration, deceleration, and idle phases. Both tests play critical roles in reducing vehicular emissions, with OBD-II focused on system diagnostics and IM240 providing direct emissions measurement.

Understanding OBD-II Emission Testing

OBD-II emission testing monitors real-time data from a vehicle's onboard diagnostics system to detect malfunctions affecting emissions control, providing immediate detection of issues related to the engine, catalytic converter, and oxygen sensors. Unlike the IM240 test, which measures tailpipe emissions during a simulated driving cycle, OBD-II testing checks the status of emission-related components and readiness monitors stored in the vehicle's computer. This approach enhances early detection of emission problems, leading to more effective diagnostics and repairs to reduce pollutants.

What is IM240 Emission Testing?

IM240 emission testing is a comprehensive vehicle emissions inspection method that measures pollutants using a 240-second driving cycle on a dynamometer, simulating urban driving conditions. It evaluates emissions of hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) to ensure compliance with stricter air quality standards. This test is more rigorous than OBD-II emission testing because it directly measures tailpipe emissions rather than just monitoring the vehicle's onboard diagnostic system.

Key Differences Between OBD-II and IM240 Testing

OBD-II emission testing monitors real-time data from a vehicle's onboard computer to detect emissions-related malfunctions, while IM240 testing measures actual exhaust emissions during a standardized 240-second driving cycle on a dynamometer. OBD-II tests are quicker, less expensive, and can identify specific system faults before they result in high emissions, whereas IM240 provides direct quantification of pollutant outputs like CO, HC, and NOx under controlled conditions. The key difference lies in OBD-II's diagnostic approach targeting system readiness and fault codes versus IM240's direct measurement of tailpipe emissions.

Advantages of OBD-II Emission Testing

OBD-II emission testing provides real-time monitoring of vehicle emissions systems, enabling quicker and more accurate detection of malfunctions compared to the IM240 dynamometer test. The system continuously records diagnostic trouble codes, which helps reduce the guesswork involved in identifying emission-related problems and lowers the likelihood of false positives. OBD-II tests are also less time-consuming and require less specialized equipment, making them more cost-effective and convenient for both technicians and vehicle owners.

Benefits of IM240 Emission Testing

IM240 emission testing offers enhanced accuracy by measuring vehicle emissions under a wider range of driving conditions, including acceleration and deceleration phases, which better simulate real-world driving. This method detects a broader spectrum of pollutants, such as hydrocarbons, carbon monoxide, and nitrogen oxides, leading to more comprehensive emissions control and environmental protection. Regulatory agencies increasingly favor IM240 for its ability to identify vehicles with emission control system failures that OBD-II testing might miss.

Limitations of OBD-II Emission Testing

OBD-II emission testing primarily monitors drivetrain components and detects emissions-related malfunctions through onboard sensors, but it cannot measure actual tailpipe emissions or capture all types of pollutants like hydrocarbons and carbon monoxide. This limitation makes OBD-II less comprehensive compared to IM240 testing, which physically measures gas concentrations during simulated driving conditions. Consequently, OBD-II may miss certain emission violations that only direct exhaust analysis can identify.

Drawbacks of IM240 Emission Testing

IM240 emission testing presents several drawbacks, including longer test durations and increased complexity compared to OBD-II emission testing, which can lead to higher costs and reduced efficiency at inspection centers. The IM240 test relies on a dynamometer and simulates city and highway driving cycles, making it less adaptable to real-world driving conditions than OBD-II monitors that continuously track vehicle performance. Limited applicability to modern vehicles and higher technician training requirements further reduce IM240's practicality in current emission testing programs.

Real-World Applications: OBD-II vs IM240

OBD-II emission testing monitors real-time engine performance by analyzing data from the vehicle's onboard diagnostic system, ensuring continuous emission control during actual driving conditions. IM240 testing relies on a controlled dynamometer setup measuring emissions during specific steady-state and transient driving cycles, which may not fully capture everyday vehicle behavior. Real-world applications favor OBD-II testing for its comprehensive and ongoing diagnostics, enabling quicker detection and repair of emission-related issues on modern vehicles.

Future Trends in Emission Testing Technologies

OBD-II emission testing leverages advanced onboard diagnostics to provide real-time data on vehicle emissions, enhancing accuracy and efficiency compared to the IM240 transient test that relies on dynamometer simulation. Future trends in emission testing technologies are shifting towards integrating remote sensing and wireless data transmission to enable continuous monitoring and predictive maintenance. Advances in machine learning algorithms and enhanced sensor calibration are expected to further reduce testing time while improving detection of emission irregularities.

OBD-II Emission Testing vs IM240 Emission Testing Infographic

cardiffo.com

cardiffo.com