Lean burn engines operate with a higher air-to-fuel ratio than stoichiometric engines, resulting in lower fuel consumption and reduced carbon monoxide and hydrocarbon emissions. Stoichiometric burn engines maintain an ideal air-to-fuel ratio that ensures complete combustion, typically resulting in lower nitrogen oxide emissions due to optimal catalyst performance. Choosing between lean burn and stoichiometric burn depends on balancing fuel efficiency with emission control requirements for specific applications.

Table of Comparison

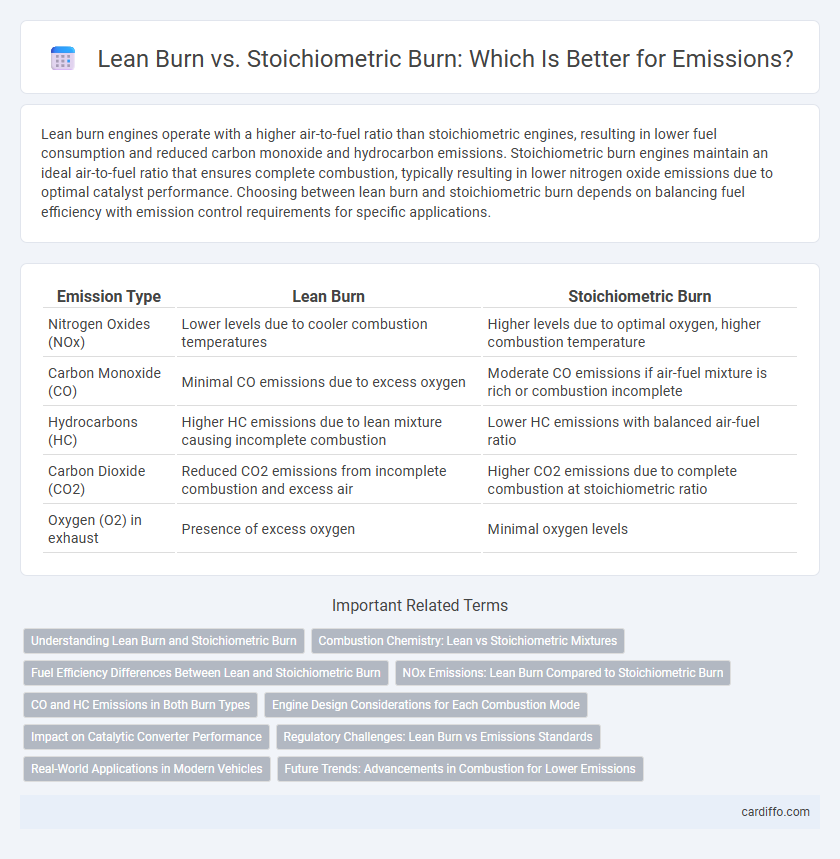

| Emission Type | Lean Burn | Stoichiometric Burn |

|---|---|---|

| Nitrogen Oxides (NOx) | Lower levels due to cooler combustion temperatures | Higher levels due to optimal oxygen, higher combustion temperature |

| Carbon Monoxide (CO) | Minimal CO emissions due to excess oxygen | Moderate CO emissions if air-fuel mixture is rich or combustion incomplete |

| Hydrocarbons (HC) | Higher HC emissions due to lean mixture causing incomplete combustion | Lower HC emissions with balanced air-fuel ratio |

| Carbon Dioxide (CO2) | Reduced CO2 emissions from incomplete combustion and excess air | Higher CO2 emissions due to complete combustion at stoichiometric ratio |

| Oxygen (O2) in exhaust | Presence of excess oxygen | Minimal oxygen levels |

Understanding Lean Burn and Stoichiometric Burn

Lean burn engines operate with an air-fuel mixture containing excess air, improving fuel efficiency and reducing carbon monoxide and hydrocarbon emissions by promoting more complete combustion. Stoichiometric burn maintains an ideal air-fuel ratio, approximately 14.7:1 for gasoline engines, ensuring complete combustion by balancing oxygen and fuel, which optimizes catalytic converter performance for minimizing nitrogen oxides and other pollutants. Understanding the differences between lean burn and stoichiometric burn is crucial for tailoring engine management strategies that meet emission regulations and enhance environmental sustainability.

Combustion Chemistry: Lean vs Stoichiometric Mixtures

Lean burn combustion utilizes an excess of air relative to the fuel, resulting in lower combustion temperatures and reduced nitrogen oxide (NOx) emissions compared to stoichiometric burn. Stoichiometric mixtures have exactly the right air-to-fuel ratio for complete combustion, maximizing energy output but producing higher levels of NOx due to higher flame temperatures. The chemistry of lean mixtures promotes a more oxidizing environment that limits carbon monoxide (CO) and unburned hydrocarbons, improving overall emission profiles in lean burn engines.

Fuel Efficiency Differences Between Lean and Stoichiometric Burn

Lean burn engines operate with excess air, enhancing fuel efficiency by promoting more complete combustion and reducing fuel consumption compared to stoichiometric burn engines, which rely on a precise air-fuel ratio. The lean burn approach results in lower fuel usage and reduced emissions of hydrocarbons and carbon monoxide, while stoichiometric combustion optimizes catalytic converter performance but typically consumes more fuel. Consequently, lean burn technology is favored in applications where maximizing fuel economy and lowering specific emissions are critical.

NOx Emissions: Lean Burn Compared to Stoichiometric Burn

Lean burn engines operate with excess air, resulting in higher combustion temperatures that increase thermal NOx formation compared to stoichiometric burn engines, which maintain an ideal air-fuel ratio for complete combustion. Although lean burn reduces hydrocarbon and CO emissions, NOx emissions typically rise due to the oxygen-rich environment promoting nitrogen oxidation. Advanced after-treatment systems like selective catalytic reduction are often required in lean burn engines to mitigate these elevated NOx levels effectively.

CO and HC Emissions in Both Burn Types

Lean burn engines operate with excess air, resulting in lower carbon monoxide (CO) and hydrocarbon (HC) emissions compared to stoichiometric burn engines, which use a precise air-fuel ratio that promotes complete combustion but can increase CO and HC under certain conditions. Stoichiometric combustion typically achieves better catalytic converter efficiency, reducing CO and HC emissions post-combustion, whereas lean burn combustion inherently produces fewer CO and HC emissions due to its oxygen-rich environment. Emission control strategies must balance lean burn's lower raw emissions with stoichiometric burn's optimal catalyst performance to minimize overall CO and HC outputs.

Engine Design Considerations for Each Combustion Mode

Lean burn engines operate with excess air, enhancing fuel efficiency and lowering emissions of hydrocarbons and carbon monoxide by promoting complete combustion, but they require advanced engine controls and combustion chamber designs to manage higher combustion temperatures and prevent NOx formation. Stoichiometric burn engines maintain an ideal air-fuel ratio near 14.7:1, allowing for efficient catalytic converter operation and simpler engine management systems, yet they tend to produce higher levels of CO and unburned hydrocarbons under certain operating conditions. Engine design considerations for lean burn include optimized intake flow, precise fuel injection, and enhanced cooling systems, while stoichiometric designs emphasize robust catalytic converters and fuel system reliability to ensure balanced emissions and performance.

Impact on Catalytic Converter Performance

Lean burn engines operate with excess air, resulting in lower combustion temperatures and reduced NOx emissions but can challenge catalytic converter efficiency due to insufficient unburned hydrocarbons needed for catalyst regeneration. Stoichiometric burn maintains an optimal air-fuel ratio (around 14.7:1), ensuring complete combustion that provides balanced emissions for catalytic converters, promoting optimal oxidation and reduction reactions. The catalytic converter's ability to reduce pollutants depends significantly on maintaining stoichiometric conditions, as lean burn can lead to oxygen-rich exhaust that impairs catalyst function.

Regulatory Challenges: Lean Burn vs Emissions Standards

Lean burn engines produce lower nitrogen oxide (NOx) emissions due to excess air, but their elevated levels of unburned hydrocarbons (HC) and carbon monoxide (CO) complicate compliance with stringent emissions standards. Stoichiometric burn engines achieve complete combustion at an air-fuel ratio of 14.7:1, enabling effective catalytic converter operation to reduce NOx, HC, and CO emissions, aligning more readily with regulatory limits. Strict emission regulations such as Euro 6 and EPA Tier 3 require advanced after-treatment systems for lean burn engines, increasing development costs and regulatory challenges.

Real-World Applications in Modern Vehicles

Lean burn engines operate with excess air, resulting in lower emissions of carbon monoxide and hydrocarbons, making them ideal for modern gasoline direct injection vehicles aiming for higher fuel efficiency. Stoichiometric burn maintains an ideal air-to-fuel ratio of 14.7:1, ensuring optimal performance of three-way catalytic converters in controlling NOx, CO, and HC emissions, commonly used in conventional gasoline engines. Real-world applications balance these combustion strategies to meet stringent emission standards while optimizing fuel economy and engine performance in diverse driving conditions.

Future Trends: Advancements in Combustion for Lower Emissions

Future trends in combustion focus on enhancing Lean Burn technology due to its ability to significantly reduce nitrogen oxide (NOx) and carbon monoxide (CO) emissions compared to stoichiometric burn. Innovations in advanced sensors and real-time engine control systems enable precise air-fuel ratio adjustments, optimizing lean burn conditions for maximum efficiency and minimal pollutants. Ongoing research in catalytic converter materials and combustion chamber design further supports lower emissions, positioning lean burn as a critical component in achieving stringent future environmental regulations.

Lean Burn vs Stoichiometric Burn Infographic

cardiffo.com

cardiffo.com