Direct injection emissions typically contain higher levels of particulate matter and nitrogen oxides compared to port injection emissions due to the precise timing and location of fuel delivery inside the combustion chamber. Port injection produces more homogeneous air-fuel mixtures, resulting in lower soot and unburned hydrocarbons but may generate higher carbon monoxide levels under certain conditions. Advances in emission control technologies are bridging the gap between these systems, optimizing combustion efficiency while minimizing harmful pollutants.

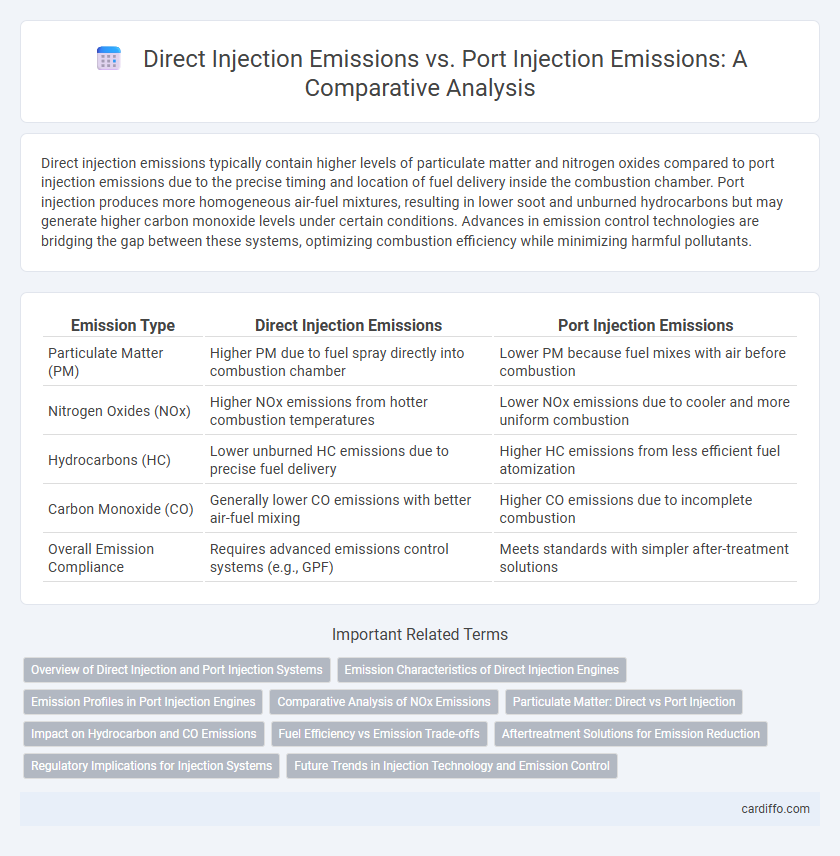

Table of Comparison

| Emission Type | Direct Injection Emissions | Port Injection Emissions |

|---|---|---|

| Particulate Matter (PM) | Higher PM due to fuel spray directly into combustion chamber | Lower PM because fuel mixes with air before combustion |

| Nitrogen Oxides (NOx) | Higher NOx emissions from hotter combustion temperatures | Lower NOx emissions due to cooler and more uniform combustion |

| Hydrocarbons (HC) | Lower unburned HC emissions due to precise fuel delivery | Higher HC emissions from less efficient fuel atomization |

| Carbon Monoxide (CO) | Generally lower CO emissions with better air-fuel mixing | Higher CO emissions due to incomplete combustion |

| Overall Emission Compliance | Requires advanced emissions control systems (e.g., GPF) | Meets standards with simpler after-treatment solutions |

Overview of Direct Injection and Port Injection Systems

Direct injection systems deliver fuel directly into the combustion chamber, enhancing fuel atomization and combustion efficiency, resulting in lower CO2 emissions but potentially higher particulate matter and NOx emissions. Port injection systems inject fuel into the intake manifold, promoting better air-fuel mixing and reducing particulate emissions, though generally producing higher CO2 levels compared to direct injection. Modern engines often combine both systems to optimize performance and emissions by balancing combustion efficiency and pollutant control.

Emission Characteristics of Direct Injection Engines

Direct injection engines exhibit distinct emission characteristics, producing lower carbon monoxide (CO) and hydrocarbon (HC) emissions due to precise fuel delivery directly into the combustion chamber. However, these engines tend to generate higher particulate matter (PM) and nitrogen oxides (NOx) emissions compared to port injection systems, necessitating advanced after-treatment technologies like particulate filters and selective catalytic reduction. Optimizing injection timing and pressure in direct injection systems is crucial for minimizing the formation of soot and NOx, thereby improving overall emission performance.

Emission Profiles in Port Injection Engines

Port injection engines exhibit lower particulate matter (PM) emissions compared to direct injection engines due to better fuel-air mixing before combustion. Nitrogen oxides (NOx) emissions in port injection systems tend to be higher under certain conditions because of less precise fuel metering than direct injection. Hydrocarbon (HC) emissions may increase slightly in port injection engines, stemming from fuel wall-wetting and incomplete combustion.

Comparative Analysis of NOx Emissions

Direct injection engines produce higher levels of nitrogen oxides (NOx) compared to port injection engines due to the concentrated fuel spray and higher combustion temperatures in the combustion chamber. Port injection reduces NOx emissions by promoting better air-fuel mixing and lower peak temperatures during combustion. Studies indicate that NOx emissions from direct injection systems can be 20-40% greater than those from port injection setups under similar operating conditions.

Particulate Matter: Direct vs Port Injection

Direct injection engines produce higher levels of particulate matter (PM) compared to port injection systems due to the concentrated fuel spray and incomplete combustion within the cylinder. Particulate emissions from direct injection can contain a significant fraction of black carbon and ultrafine particles, which contribute to air pollution and respiratory issues. Port injection engines mix fuel with intake air before entering the combustion chamber, reducing PM formation through better vaporization and more homogeneous combustion.

Impact on Hydrocarbon and CO Emissions

Direct injection engines typically produce higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to port injection engines due to incomplete fuel atomization and wall wetting within the combustion chamber. Port injection systems mix fuel with intake air, promoting more homogeneous combustion, which results in lower HC and CO emissions. Advances in direct injection technology, such as optimized injector design and combustion chamber geometry, aim to reduce these emissions but challenges remain in meeting stringent environmental standards.

Fuel Efficiency vs Emission Trade-offs

Direct injection engines improve fuel efficiency by injecting fuel directly into the combustion chamber, allowing for precise fuel control and higher compression ratios that boost power output. However, this method tends to increase particulate matter and nitrogen oxide (NOx) emissions due to localized rich combustion zones. In contrast, port injection reduces particulate emissions by premixing fuel and air before combustion but sacrifices some fuel efficiency and power, creating a trade-off between lower emissions and optimal fuel consumption.

Aftertreatment Solutions for Emission Reduction

Direct injection emissions typically contain higher levels of particulate matter and unburned hydrocarbons compared to port injection emissions, necessitating advanced aftertreatment solutions like diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems for effective reduction. Port injection emissions, characterized by relatively lower particulate content, still benefit from three-way catalysts and oxidation catalysts to minimize NOx and CO emissions. Optimizing aftertreatment strategies tailored to injection methods significantly enhances compliance with stringent emission standards and improves overall air quality.

Regulatory Implications for Injection Systems

Direct injection emissions exhibit higher particulate matter and nitrogen oxide levels compared to port injection, prompting stricter regulatory scrutiny on particulate filters and catalytic converters. Regulatory bodies increasingly mandate advanced emission control technologies for direct injection systems to meet Euro 6 and EPA Tier 3 standards. Compliance challenges drive automotive manufacturers to optimize fuel injection strategies and integrate exhaust after-treatment systems to reduce regulatory non-compliance risks.

Future Trends in Injection Technology and Emission Control

Direct injection (DI) technology offers improved fuel atomization and precise control over injection timing, resulting in lower CO2 emissions compared to port fuel injection (PFI). Future trends emphasize advanced DI systems integrated with optimized combustion strategies and particulate filters to address NOx and particulate matter challenges. Innovations in injection pressure, multiple injection events, and fuel atomization are critical for meeting tighter emission regulations and improving engine efficiency.

Direct injection emissions vs port injection emissions Infographic

cardiffo.com

cardiffo.com