Exhaust Gas Recirculation (EGR) reduces nitrogen oxide emissions by recirculating a portion of the engine's exhaust gas back to the combustion chamber, lowering combustion temperatures. Positive Crankcase Ventilation (PCV) controls engine emissions by redirecting blow-by gases from the crankcase into the intake manifold for re-combustion, preventing harmful hydrocarbons from escaping into the atmosphere. Both EGR and PCV systems are crucial for meeting emission standards and improving air quality in modern vehicles.

Table of Comparison

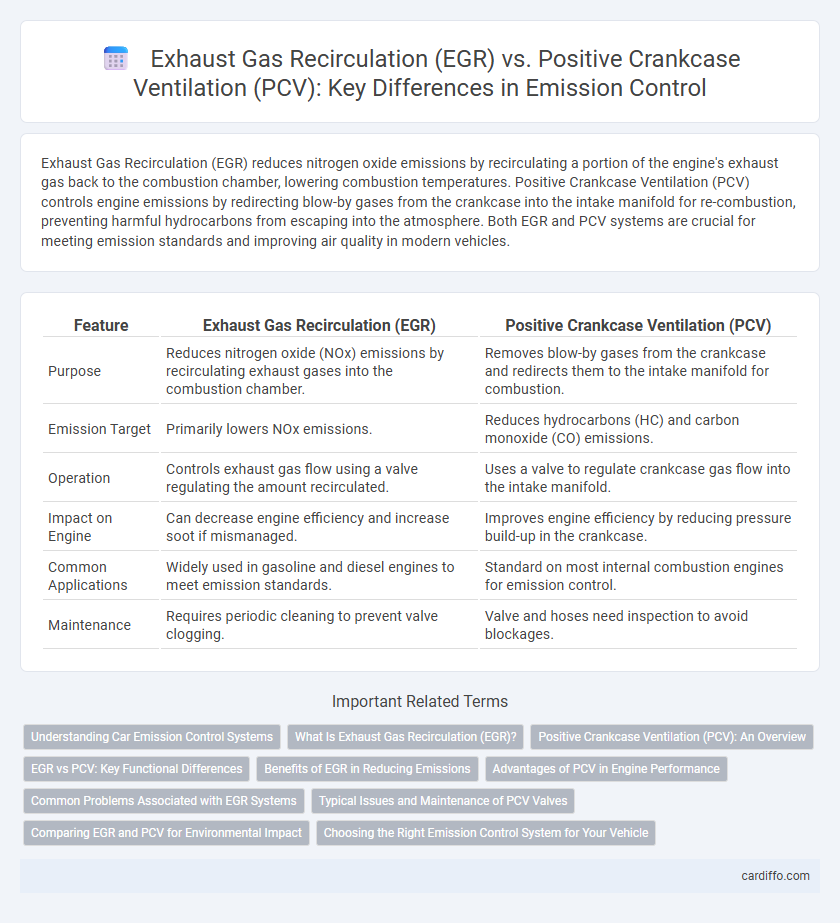

| Feature | Exhaust Gas Recirculation (EGR) | Positive Crankcase Ventilation (PCV) |

|---|---|---|

| Purpose | Reduces nitrogen oxide (NOx) emissions by recirculating exhaust gases into the combustion chamber. | Removes blow-by gases from the crankcase and redirects them to the intake manifold for combustion. |

| Emission Target | Primarily lowers NOx emissions. | Reduces hydrocarbons (HC) and carbon monoxide (CO) emissions. |

| Operation | Controls exhaust gas flow using a valve regulating the amount recirculated. | Uses a valve to regulate crankcase gas flow into the intake manifold. |

| Impact on Engine | Can decrease engine efficiency and increase soot if mismanaged. | Improves engine efficiency by reducing pressure build-up in the crankcase. |

| Common Applications | Widely used in gasoline and diesel engines to meet emission standards. | Standard on most internal combustion engines for emission control. |

| Maintenance | Requires periodic cleaning to prevent valve clogging. | Valve and hoses need inspection to avoid blockages. |

Understanding Car Emission Control Systems

Exhaust Gas Recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber, lowering combustion temperature and preventing NOx formation. Positive Crankcase Ventilation (PCV) controls blow-by gases by redirecting them from the crankcase into the intake manifold, minimizing hydrocarbon emissions and improving engine efficiency. Both EGR and PCV are critical components in car emission control systems, targeting different pollutants to comply with stringent environmental regulations.

What Is Exhaust Gas Recirculation (EGR)?

Exhaust Gas Recirculation (EGR) is an advanced emission control technology designed to reduce nitrogen oxide (NOx) emissions by recirculating a portion of an engine's exhaust gas back to the combustion chamber. This process lowers combustion temperatures, which inhibits the formation of harmful NOx pollutants. EGR systems are essential in meeting stringent emission standards and improving overall engine efficiency.

Positive Crankcase Ventilation (PCV): An Overview

Positive Crankcase Ventilation (PCV) is a crucial emission control system designed to reduce harmful pollutants by redirecting blow-by gases from the engine crankcase back into the combustion chamber for reburning. It significantly decreases hydrocarbon emissions and prevents oil contamination, enhancing engine efficiency and longevity. PCV systems contribute to compliance with stringent emission standards such as those set by the Environmental Protection Agency (EPA) and Euro 6 regulations.

EGR vs PCV: Key Functional Differences

Exhaust Gas Recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber to lower combustion temperatures. Positive Crankcase Ventilation (PCV) controls crankcase emissions by redirecting blow-by gases into the intake manifold for re-combustion, thus preventing the release of unburned hydrocarbons. EGR primarily targets NOx reduction, while PCV focuses on minimizing crankcase hydrocarbon emissions and pressure buildup.

Benefits of EGR in Reducing Emissions

Exhaust Gas Recirculation (EGR) significantly reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber, which lowers combustion temperatures and minimizes the formation of harmful pollutants. EGR improves engine efficiency and reduces smog-causing emissions compared to Positive Crankcase Ventilation (PCV), which primarily controls crankcase vapors but has limited impact on NOx reduction. This technology is critical in meeting stringent emission regulations and enhancing overall air quality.

Advantages of PCV in Engine Performance

Positive Crankcase Ventilation (PCV) improves engine performance by reducing harmful emissions and preventing oil contamination, which enhances overall engine efficiency and longevity. PCV systems decrease sludge buildup and maintain cleaner intake valves compared to Exhaust Gas Recirculation (EGR) systems, resulting in better combustion and lower maintenance costs. Additionally, PCV contributes to improved fuel economy by optimizing air-fuel mixture balance and reducing crankcase pressure.

Common Problems Associated with EGR Systems

Common problems associated with Exhaust Gas Recirculation (EGR) systems include valve clogging due to carbon buildup, which restricts exhaust flow and reduces engine efficiency. EGR cooler leaks can lead to coolant contamination and engine overheating, causing severe mechanical damage. Faulty EGR valves often trigger engine performance issues like rough idling, reduced fuel economy, and increased emissions, necessitating timely inspection and maintenance.

Typical Issues and Maintenance of PCV Valves

PCV valves often face clogging and sludge buildup due to oil vapor and combustion byproducts, impairing their function and leading to increased emissions and engine performance issues. Regular inspection and cleaning or timely replacement of PCV valves are essential to prevent vacuum leaks, rough idling, and potential engine damage. Maintaining a properly functioning PCV system helps reduce crankcase pressure and minimizes harmful hydrocarbon emissions, ensuring compliance with emission standards.

Comparing EGR and PCV for Environmental Impact

Exhaust Gas Recirculation (EGR) reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber, lowering combustion temperature and thus controlling smog formation. Positive Crankcase Ventilation (PCV) minimizes hydrocarbon emissions by redirecting blow-by gases from the crankcase into the intake manifold for re-burn, preventing the release of unburned fuel vapors into the atmosphere. Both systems contribute to emission reduction, with EGR primarily targeting NOx control and PCV focusing on the reduction of volatile organic compounds (VOCs).

Choosing the Right Emission Control System for Your Vehicle

Exhaust Gas Recirculation (EGR) reduces nitrogen oxide emissions by recirculating a portion of exhaust gases back into the combustion chamber, optimizing combustion temperature and efficiency. Positive Crankcase Ventilation (PCV) controls emissions by redirecting blow-by gases from the crankcase into the intake manifold, preventing harmful hydrocarbons from escaping into the atmosphere. Selecting the appropriate system depends on your vehicle's engine type, operational conditions, and emission reduction priorities, with EGR ideal for NOx control and PCV focusing on minimizing crankcase emissions.

Exhaust Gas Recirculation (EGR) vs Positive Crankcase Ventilation (PCV) Infographic

cardiffo.com

cardiffo.com