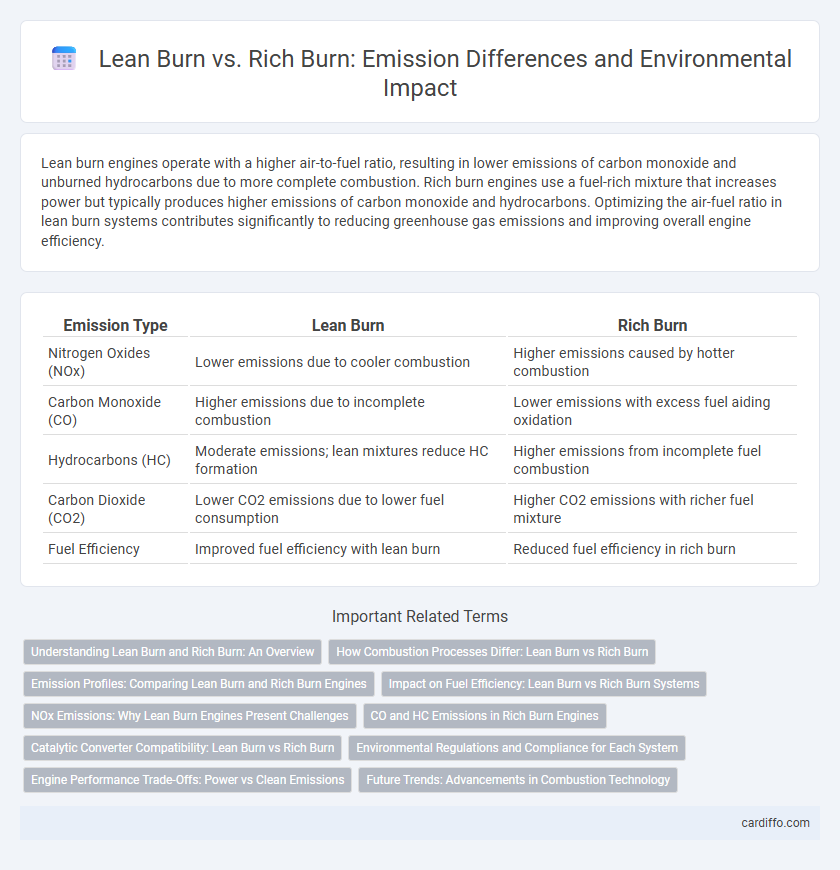

Lean burn engines operate with a higher air-to-fuel ratio, resulting in lower emissions of carbon monoxide and unburned hydrocarbons due to more complete combustion. Rich burn engines use a fuel-rich mixture that increases power but typically produces higher emissions of carbon monoxide and hydrocarbons. Optimizing the air-fuel ratio in lean burn systems contributes significantly to reducing greenhouse gas emissions and improving overall engine efficiency.

Table of Comparison

| Emission Type | Lean Burn | Rich Burn |

|---|---|---|

| Nitrogen Oxides (NOx) | Lower emissions due to cooler combustion | Higher emissions caused by hotter combustion |

| Carbon Monoxide (CO) | Higher emissions due to incomplete combustion | Lower emissions with excess fuel aiding oxidation |

| Hydrocarbons (HC) | Moderate emissions; lean mixtures reduce HC formation | Higher emissions from incomplete fuel combustion |

| Carbon Dioxide (CO2) | Lower CO2 emissions due to lower fuel consumption | Higher CO2 emissions with richer fuel mixture |

| Fuel Efficiency | Improved fuel efficiency with lean burn | Reduced fuel efficiency in rich burn |

Understanding Lean Burn and Rich Burn: An Overview

Lean burn engines operate with an excess of air relative to fuel, resulting in lower fuel consumption and reduced emissions of carbon monoxide and hydrocarbons. Rich burn engines use a higher fuel-to-air ratio, producing greater power but increasing emissions of carbon monoxide and unburned hydrocarbons. Understanding the trade-offs between lean burn's fuel efficiency and reduced emissions versus rich burn's higher power output is critical for optimizing engine performance and environmental impact.

How Combustion Processes Differ: Lean Burn vs Rich Burn

Lean burn combustion operates with an excess of air, maintaining an air-fuel ratio greater than stoichiometric, which results in lower emissions of carbon monoxide and hydrocarbons due to more complete oxidation. Rich burn combustion uses a fuel-heavy mixture with an air-fuel ratio below stoichiometric, producing higher power output but increasing emissions of carbon monoxide, hydrocarbons, and particulate matter due to incomplete combustion. The fundamental difference lies in the air-fuel mixture ratio, directly impacting combustion efficiency, temperature, and pollutant formation.

Emission Profiles: Comparing Lean Burn and Rich Burn Engines

Lean burn engines produce lower carbon monoxide (CO) and hydrocarbon (HC) emissions due to more complete combustion with excess air, resulting in reduced particulate matter formation. Rich burn engines, running with a fuel-rich mixture, generate higher CO and HC emissions but typically lower nitrogen oxides (NOx) because of cooler combustion temperatures. The trade-off between these emission profiles makes lean burn engines preferable for minimizing overall pollutant output in modern emission control strategies.

Impact on Fuel Efficiency: Lean Burn vs Rich Burn Systems

Lean burn systems operate with excess air, promoting more complete combustion and significantly enhancing fuel efficiency by reducing fuel consumption. Rich burn systems use a higher fuel-to-air ratio, resulting in higher emissions and lower fuel efficiency due to incomplete combustion and increased fuel wastage. Optimizing engine performance through lean burn technology can reduce fuel costs and emissions, providing a more sustainable solution for combustion engines.

NOx Emissions: Why Lean Burn Engines Present Challenges

Lean burn engines operate with excess air, which lowers combustion temperatures but leads to higher oxygen content in the exhaust, complicating NOx emissions control. Although lean combustion reduces CO and HC pollutants, the high oxygen environment limits the efficiency of traditional three-way catalysts for NOx reduction. Consequently, advanced aftertreatment technologies like lean NOx traps or selective catalytic reduction are required to meet stringent emission standards.

CO and HC Emissions in Rich Burn Engines

Rich burn engines typically produce higher carbon monoxide (CO) and hydrocarbon (HC) emissions compared to lean burn engines due to incomplete combustion caused by excess fuel. The elevated fuel-to-air ratio in rich burn conditions limits oxygen availability, resulting in unoxidized hydrocarbons and carbon monoxide remaining in the exhaust. Emission control technologies such as catalytic converters are often necessary to reduce these pollutants in rich burn engine exhaust streams.

Catalytic Converter Compatibility: Lean Burn vs Rich Burn

Catalytic converter compatibility varies significantly between lean burn and rich burn engines, with rich burn engines generally producing exhaust gases that are more conducive to efficient catalytic converter operation due to higher concentrations of carbon monoxide and unburned hydrocarbons. Lean burn engines emit lower levels of these pollutants but higher levels of nitrogen oxides (NOx), requiring advanced three-way catalytic converters or selective catalytic reduction systems to effectively reduce emissions. The choice of catalytic converter technology must align with the engine's air-fuel ratio to optimize pollutant conversion and meet stringent emission standards.

Environmental Regulations and Compliance for Each System

Lean burn engines operate with excess air, significantly reducing nitrogen oxide (NOx) emissions to meet stringent environmental regulations such as Euro 6 and Tier 3 standards. Rich burn engines produce higher hydrocarbon and carbon monoxide emissions, requiring advanced catalytic converters to comply with emissions limits imposed by the Environmental Protection Agency (EPA) and similar regulatory bodies. Compliance strategies for lean burn systems emphasize precise air-fuel ratio control, while rich burn engines rely heavily on after-treatment technologies to achieve legal emission thresholds.

Engine Performance Trade-Offs: Power vs Clean Emissions

Lean burn engines optimize air-to-fuel ratios by using excess air, resulting in improved fuel efficiency and lower NOx and CO emissions but often at the cost of reduced peak power output. Rich burn engines run with excess fuel, providing higher power and better throttle response while producing increased levels of hydrocarbons and carbon monoxide pollutants. Balancing engine performance requires managing the trade-off between maximizing power and minimizing harmful emissions, with lean burn favoring cleaner exhaust and rich burn prioritizing engine responsiveness and power.

Future Trends: Advancements in Combustion Technology

Future trends in combustion technology emphasize lean burn systems, which enhance fuel efficiency and significantly reduce nitrogen oxide (NOx) emissions compared to rich burn engines. Advancements in precise fuel-air mixture control and improved ignition systems enable lean burn engines to operate with lower excess air, optimizing combustion and minimizing pollutants. Emerging technologies such as variable valve timing and advanced sensor integration further support the transition toward cleaner, more efficient lean burn combustion processes.

Lean Burn vs Rich Burn Infographic

cardiffo.com

cardiffo.com