DPF regeneration and SCR operation are critical processes for reducing diesel engine emissions, with DPF regeneration targeting the removal of particulate matter by burning off soot accumulated in the filter. SCR operation works by injecting urea-based DEF into the exhaust stream, converting nitrogen oxides (NOx) into harmless nitrogen and water through a catalytic reaction. Together, these technologies optimize emission control by tackling both particulate emissions and NOx pollutants to comply with stringent environmental standards.

Table of Comparison

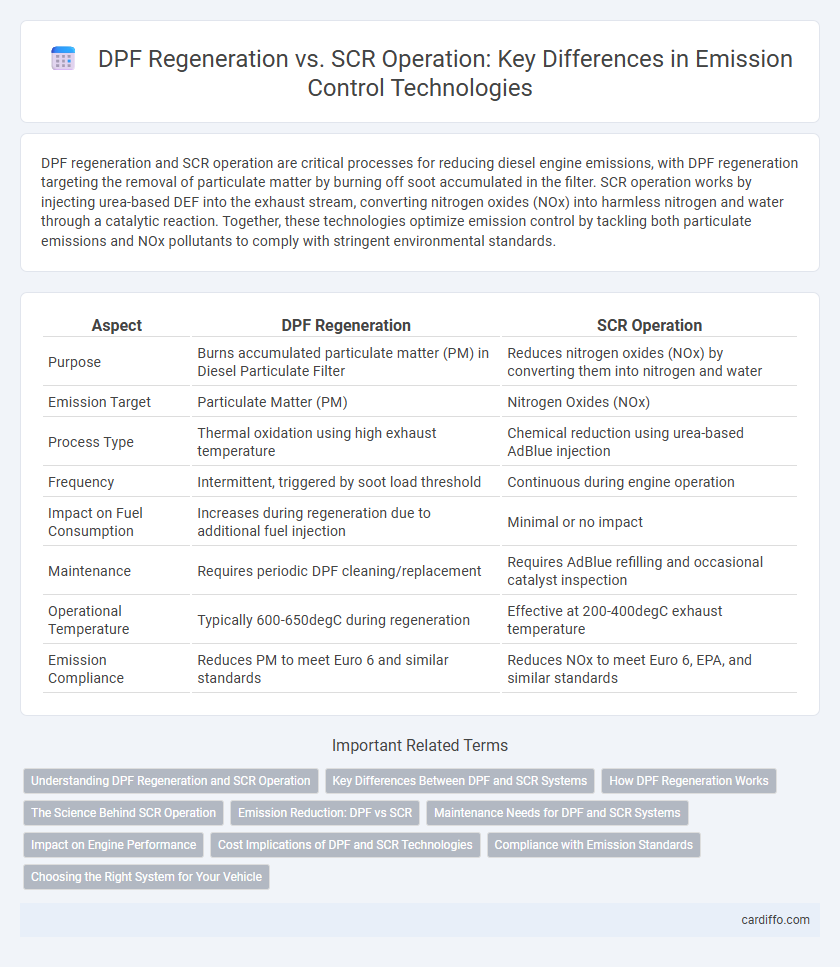

| Aspect | DPF Regeneration | SCR Operation |

|---|---|---|

| Purpose | Burns accumulated particulate matter (PM) in Diesel Particulate Filter | Reduces nitrogen oxides (NOx) by converting them into nitrogen and water |

| Emission Target | Particulate Matter (PM) | Nitrogen Oxides (NOx) |

| Process Type | Thermal oxidation using high exhaust temperature | Chemical reduction using urea-based AdBlue injection |

| Frequency | Intermittent, triggered by soot load threshold | Continuous during engine operation |

| Impact on Fuel Consumption | Increases during regeneration due to additional fuel injection | Minimal or no impact |

| Maintenance | Requires periodic DPF cleaning/replacement | Requires AdBlue refilling and occasional catalyst inspection |

| Operational Temperature | Typically 600-650degC during regeneration | Effective at 200-400degC exhaust temperature |

| Emission Compliance | Reduces PM to meet Euro 6 and similar standards | Reduces NOx to meet Euro 6, EPA, and similar standards |

Understanding DPF Regeneration and SCR Operation

DPF regeneration involves burning off accumulated soot particles in the Diesel Particulate Filter to reduce particulate emissions and maintain filter efficiency. SCR operation uses a catalyst and a reductant, typically urea-based Diesel Exhaust Fluid (DEF), to convert nitrogen oxides (NOx) emissions into harmless nitrogen and water vapor. Both technologies are critical for meeting stringent emission standards by targeting particulate matter and NOx pollutants in diesel engines.

Key Differences Between DPF and SCR Systems

DPF regeneration involves the periodic burning of accumulated soot particles within the Diesel Particulate Filter to reduce particulate matter emissions, whereas SCR operation uses a urea-based reductant to convert nitrogen oxides (NOx) into harmless nitrogen and water vapor. DPF systems primarily target particulate matter reduction, while SCR systems focus on minimizing NOx emissions, each employing distinct aftertreatment processes. Understanding these key differences is critical for optimizing diesel engine emission controls and complying with stringent environmental regulations.

How DPF Regeneration Works

DPF regeneration is a process that removes accumulated soot particles from the Diesel Particulate Filter by raising the filter temperature to typically above 600degC, allowing the trapped particulates to oxidize into less harmful gases. This combustion of soot is either passive, occurring during normal exhaust temperatures, or active, where additional fuel is injected to increase exhaust temperature for effective regeneration. Proper DPF regeneration ensures reduced particulate emissions, enhances filter longevity, and maintains optimal engine performance.

The Science Behind SCR Operation

Selective Catalytic Reduction (SCR) operation relies on a chemical process in which a urea-based diesel exhaust fluid (DEF) is injected into the exhaust stream, converting nitrogen oxides (NOx) into harmless nitrogen and water vapor through catalytic reactions. The SCR catalyst typically consists of materials like titanium dioxide, vanadium pentoxide, and tungsten trioxide, which facilitate the reduction of NOx at temperatures between 200degC and 450degC. This process significantly reduces harmful emissions, ensuring compliance with stringent environmental regulations and improving air quality.

Emission Reduction: DPF vs SCR

Diesel Particulate Filters (DPF) effectively reduce particulate matter emissions by capturing soot and periodically regenerating through high-temperature oxidation. Selective Catalytic Reduction (SCR) systems target nitrogen oxide (NOx) emissions, converting them into nitrogen and water using a urea-based reductant. Combining DPF and SCR technologies optimizes overall emission reduction, addressing both particulate and NOx pollutants to meet stringent environmental standards.

Maintenance Needs for DPF and SCR Systems

DPF regeneration requires periodic ash cleaning and filter replacement due to soot accumulation, impacting maintenance frequency and costs. SCR systems demand continuous replenishment of DEF (Diesel Exhaust Fluid) and regular monitoring of catalyst efficiency to prevent ammonia slip and maintain NOx reduction. Preventive maintenance for DPF centers on thermal management and pressure sensors, while SCR focuses on injector function and DEF quality control.

Impact on Engine Performance

DPF regeneration temporarily increases exhaust backpressure, which can reduce engine efficiency and fuel economy during the process. SCR operation optimizes NOx reduction without significantly affecting engine performance, as it functions downstream in the exhaust system. Balancing DPF regeneration frequency and SCR catalyst activity is crucial for maintaining optimal engine power and emissions compliance.

Cost Implications of DPF and SCR Technologies

DPF regeneration involves periodic fuel consumption spikes to burn off soot deposits, resulting in increased operational costs due to higher fuel usage and potential maintenance needs. SCR operation requires the continuous supply of diesel exhaust fluid (DEF), adding expenses for fluid purchase and system maintenance but typically offers improved fuel efficiency and lower overall NOx emissions. Evaluating cost implications involves balancing DPF's fuel penalties and maintenance expenses against SCR's fluid and system costs within emission control strategies.

Compliance with Emission Standards

DPF regeneration reduces particulate matter (PM) by burning accumulated soot, ensuring diesel engines meet stringent PM emission limits under Euro 6 and EPA standards. SCR operation focuses on reducing nitrogen oxides (NOx) through selective catalytic reduction using urea-based DEF, achieving compliance with NOx thresholds set by regulations like Euro VI and Tier 4 Final. Combining DPF and SCR technologies enables vehicles to meet comprehensive emission standards by effectively controlling both PM and NOx pollutants.

Choosing the Right System for Your Vehicle

DPF regeneration and SCR operation serve distinct roles in vehicle emission control, with DPF targeting particulate matter and SCR focusing on nitrogen oxides reduction. Choosing the right system depends on vehicle type, engine configuration, and emission standards compliance, as DPF suits diesel engines with high soot output while SCR excels in reducing NOx in heavy-duty applications. Optimizing fuel efficiency and maintenance schedules aligns with selecting the system that ensures regulatory adherence and durability under specific driving conditions.

DPF Regeneration vs SCR Operation Infographic

cardiffo.com

cardiffo.com