Closed-loop emission control systems continuously monitor and adjust exhaust outputs using feedback sensors, ensuring precise regulation and reduced pollutant levels. Open-loop systems operate without real-time feedback, relying on preset parameters that may lead to higher emissions under varying conditions. Implementing closed-loop technology enhances emission efficiency and compliance with environmental standards.

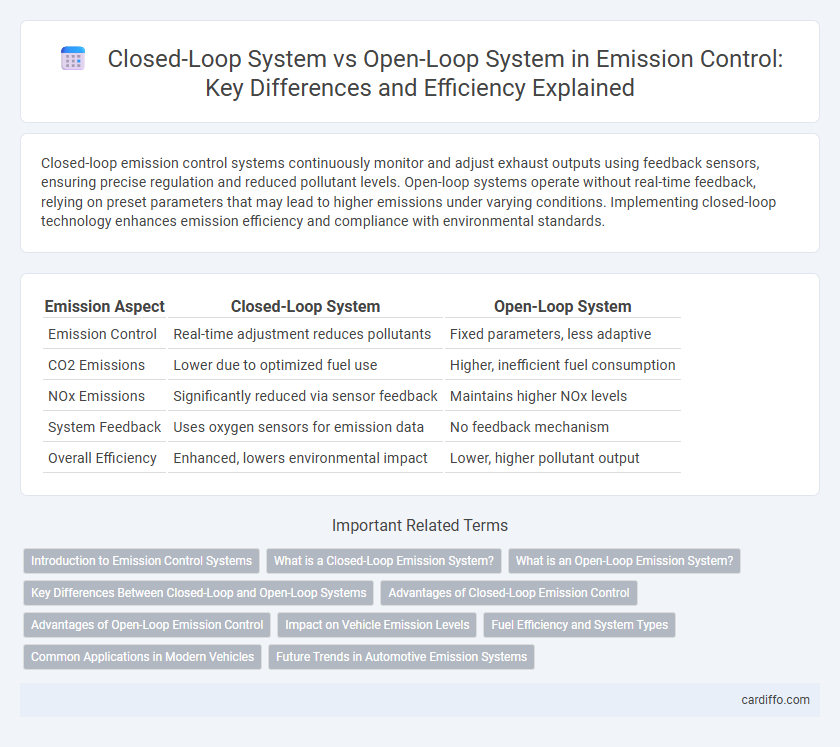

Table of Comparison

| Emission Aspect | Closed-Loop System | Open-Loop System |

|---|---|---|

| Emission Control | Real-time adjustment reduces pollutants | Fixed parameters, less adaptive |

| CO2 Emissions | Lower due to optimized fuel use | Higher, inefficient fuel consumption |

| NOx Emissions | Significantly reduced via sensor feedback | Maintains higher NOx levels |

| System Feedback | Uses oxygen sensors for emission data | No feedback mechanism |

| Overall Efficiency | Enhanced, lowers environmental impact | Lower, higher pollutant output |

Introduction to Emission Control Systems

Closed-loop emission control systems utilize real-time feedback from sensors to continuously adjust fuel injection and air-fuel ratios, significantly reducing harmful exhaust emissions. In contrast, open-loop systems operate without feedback, relying on preset parameters that can lead to less efficient emission control and higher pollutant output. Advanced closed-loop systems integrate oxygen sensors and electronic control units, optimizing combustion and minimizing emissions of nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC).

What is a Closed-Loop Emission System?

A closed-loop emission system continuously monitors exhaust gases using oxygen sensors to adjust the air-fuel mixture in real time, ensuring optimal combustion and minimizing harmful emissions. This system contrasts with open-loop systems that operate without feedback control, often leading to less efficient emission regulation. Closed-loop systems enhance fuel efficiency and reduce pollutants by maintaining balanced engine performance based on real-time sensor data.

What is an Open-Loop Emission System?

An open-loop emission system releases exhaust gases directly into the environment without recirculating or treating them for pollutants. This system lacks feedback control mechanisms to adjust emissions in real-time, resulting in higher levels of unregulated pollutants such as nitrogen oxides (NOx) and hydrocarbons. Open-loop systems are commonly found in older engines and industrial processes where emission standards are less stringent or controls are minimal.

Key Differences Between Closed-Loop and Open-Loop Systems

Closed-loop systems continuously monitor emissions through real-time feedback controls, allowing automatic adjustments to optimize performance and reduce pollutants efficiently. In contrast, open-loop systems operate without feedback, relying on preset parameters, which can result in less precise emission control and higher variability. The key difference lies in the feedback mechanism, with closed-loop systems offering greater accuracy and adaptability in emission management compared to the fixed, less responsive nature of open-loop systems.

Advantages of Closed-Loop Emission Control

Closed-loop emission control systems provide real-time monitoring and adjustment of exhaust gases, significantly reducing pollutants such as CO, NOx, and unburned hydrocarbons compared to open-loop systems. These systems utilize oxygen sensors and feedback loops to optimize air-fuel ratios, ensuring more efficient combustion and lower emissions under varying engine loads and environmental conditions. Enhanced fuel efficiency and compliance with stringent environmental regulations are key advantages driving the adoption of closed-loop emission control technologies in automotive and industrial applications.

Advantages of Open-Loop Emission Control

Open-loop emission control systems offer advantages such as lower complexity and cost compared to closed-loop systems, making them suitable for applications with less stringent emission requirements. They provide immediate response without reliance on feedback sensors, reducing delay in control actions. Open-loop systems are also more robust in harsh environments where sensor accuracy or durability may be compromised.

Impact on Vehicle Emission Levels

Closed-loop systems continuously monitor and adjust the air-fuel mixture using oxygen sensors, significantly reducing vehicle emission levels by optimizing combustion efficiency. Open-loop systems operate without real-time feedback, often resulting in richer fuel mixtures and higher emissions of hydrocarbons and carbon monoxide. Emission control regulations increasingly favor closed-loop technology due to its superior ability to minimize pollutant output and improve fuel economy.

Fuel Efficiency and System Types

Closed-loop systems use real-time feedback from sensors to continuously adjust fuel injection, optimizing fuel efficiency and reducing emissions compared to open-loop systems that operate on preset parameters without sensor input. Open-loop systems lack the ability to adjust fuel delivery based on engine operating conditions, resulting in less precise combustion control and higher fuel consumption. Advanced closed-loop systems, such as those using oxygen sensors and electronic control units (ECUs), significantly enhance fuel economy and minimize pollutant output by maintaining optimal air-fuel ratios.

Common Applications in Modern Vehicles

Closed-loop emission control systems are widely used in modern vehicles to continuously monitor and adjust the air-fuel mixture, optimizing combustion efficiency and reducing harmful pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides. Open-loop systems, still found in some older or less complex vehicles, operate without feedback from oxygen sensors, leading to less precise emission control and higher pollutant output. Advanced vehicles commonly employ closed-loop systems combined with catalytic converters and onboard diagnostics to meet stringent emission regulations and improve fuel economy.

Future Trends in Automotive Emission Systems

Future trends in automotive emission systems emphasize the shift from open-loop to closed-loop systems due to the latter's superior ability to continuously monitor and adjust fuel-air mixtures for optimal combustion and minimal emissions. Advanced sensors coupled with real-time data analytics enhance closed-loop control, significantly reducing nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM) emissions. Integration of artificial intelligence and machine learning algorithms promises further improvements in emission reduction, efficiency, and compliance with stringent global environmental regulations.

Closed-Loop System vs Open-Loop System Infographic

cardiffo.com

cardiffo.com