Catalytic converter efficiency primarily targets the reduction of harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides by facilitating chemical reactions that convert these pollutants into less harmful substances. Diesel particulate filter performance centers on capturing and removing fine particulate matter, particularly soot, from diesel exhaust to minimize airborne particle emissions. Both technologies are essential for emission control, yet catalytic converters are more effective for gaseous pollutants, while diesel particulate filters excel in reducing particulate emissions.

Table of Comparison

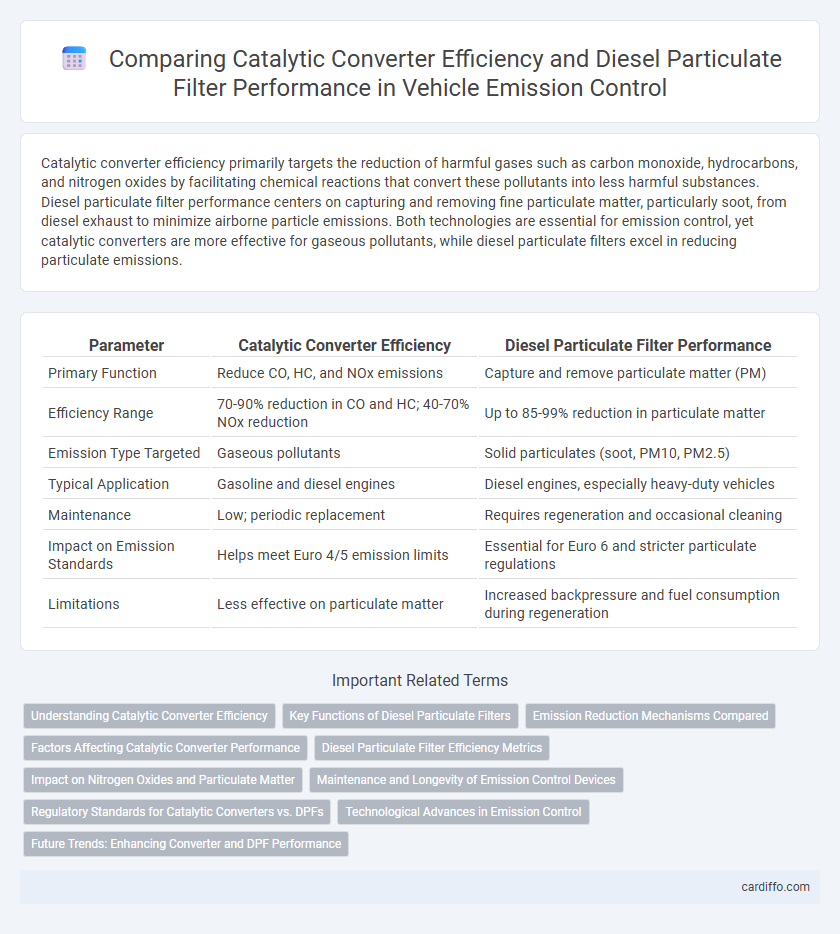

| Parameter | Catalytic Converter Efficiency | Diesel Particulate Filter Performance |

|---|---|---|

| Primary Function | Reduce CO, HC, and NOx emissions | Capture and remove particulate matter (PM) |

| Efficiency Range | 70-90% reduction in CO and HC; 40-70% NOx reduction | Up to 85-99% reduction in particulate matter |

| Emission Type Targeted | Gaseous pollutants | Solid particulates (soot, PM10, PM2.5) |

| Typical Application | Gasoline and diesel engines | Diesel engines, especially heavy-duty vehicles |

| Maintenance | Low; periodic replacement | Requires regeneration and occasional cleaning |

| Impact on Emission Standards | Helps meet Euro 4/5 emission limits | Essential for Euro 6 and stricter particulate regulations |

| Limitations | Less effective on particulate matter | Increased backpressure and fuel consumption during regeneration |

Understanding Catalytic Converter Efficiency

Catalytic converter efficiency is measured by its ability to convert harmful gases like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less toxic emissions such as carbon dioxide (CO2), water vapor, and nitrogen. Factors influencing this efficiency include catalyst composition, temperature range between 400degC and 800degC, and proper oxygen sensor feedback for optimal air-fuel mixture control. Understanding these parameters helps optimize emission reduction and meets stringent environmental regulations.

Key Functions of Diesel Particulate Filters

Diesel Particulate Filters (DPFs) are engineered to capture and remove particulate matter (PM) from diesel engine exhaust, reducing soot emissions significantly compared to catalytic converters. Unlike catalytic converters that primarily target carbon monoxide, hydrocarbons, and nitrogen oxides, DPFs focus on filtering ultrafine particles through a porous substrate. The key functions of DPFs include trapping soot, facilitating periodic regeneration to burn off accumulated particles, and maintaining optimal backpressure to ensure engine efficiency and reduced emissions.

Emission Reduction Mechanisms Compared

Catalytic converters reduce emissions primarily by converting harmful gases such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less harmful substances like carbon dioxide (CO2), water vapor, and nitrogen through oxidation and reduction reactions. Diesel particulate filters (DPFs) capture and oxidize particulate matter (PM), specifically soot, by trapping these particles in a porous filter substrate and periodically regenerating through high-temperature combustion. While catalytic converters target gaseous pollutants, DPFs are specialized in reducing particulate emissions, making both essential for comprehensive emission control in diesel engines.

Factors Affecting Catalytic Converter Performance

Catalytic converter efficiency is primarily influenced by factors such as exhaust gas temperature, oxygen sensor accuracy, and catalyst material quality, which directly impact the conversion of harmful gases like CO, NOx, and hydrocarbons into less toxic emissions. In contrast, diesel particulate filter performance depends heavily on soot loading, regeneration efficiency, and back pressure effects within the exhaust system. Optimizing catalytic converter performance requires precise control of exhaust conditions and regular maintenance to prevent catalyst poisoning and ensure maximum pollutant conversion.

Diesel Particulate Filter Efficiency Metrics

Diesel Particulate Filter (DPF) efficiency is primarily measured by its ability to capture particulate matter (PM) from diesel exhaust, typically achieving filtration efficiencies exceeding 85-99% for PM mass. Critical metrics include PM mass reduction, pressure drop across the filter, and regeneration frequency, which directly impact engine performance and emission levels. These parameters optimize the DPF's effectiveness in reducing black carbon and ultrafine particles, surpassing catalytic converter capabilities in particulate removal.

Impact on Nitrogen Oxides and Particulate Matter

Catalytic converters primarily reduce nitrogen oxides (NOx) emissions by converting them into nitrogen and oxygen through redox reactions, achieving up to 90% NOx reduction under optimal conditions. Diesel particulate filters (DPFs) trap particulate matter (PM), including soot and ash, with filtration efficiencies exceeding 85%, significantly lowering PM emissions from diesel engines. Combining catalytic converters with DPFs enhances overall emission control by simultaneously targeting NOx and particulate matter, thereby improving air quality and meeting stringent environmental regulations.

Maintenance and Longevity of Emission Control Devices

Catalytic converter efficiency depends heavily on regular maintenance to prevent catalyst poisoning and ensure optimal chemical reactions for reducing NOx and CO emissions, while diesel particulate filter (DPF) performance requires periodic regeneration or cleaning to remove trapped soot and maintain backpressure within engine specifications. Neglecting maintenance can significantly reduce the longevity of both devices, with catalytic converters suffering from decreased conversion rates and DPFs facing clogging risks that increase fuel consumption and emissions. Implementing timely inspections and tailored service intervals based on engine operation conditions enhances the durability and sustained emission control effectiveness of these critical emission control devices.

Regulatory Standards for Catalytic Converters vs. DPFs

Catalytic converters must meet stringent regulatory standards such as Euro 6 and Tier 3, targeting reductions in nitrogen oxides (NOx) and carbon monoxide (CO) emissions through oxidation and reduction reactions. Diesel particulate filters (DPFs) are regulated primarily under the same frameworks but emphasize capturing and oxidizing particulate matter (PM) to comply with limits on soot and fine particle emissions. Compliance with these standards ensures both catalytic converters and DPFs significantly reduce harmful pollutants, but DPF performance is crucial for controlling diesel particulate emissions, which catalytic converters cannot address effectively.

Technological Advances in Emission Control

Catalytic converters have improved significantly in converting harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic substances, achieving conversion efficiencies above 90% under optimal conditions. Diesel particulate filters (DPFs) excel at trapping fine particulate matter, reducing particulate emissions by over 85%, utilizing advances in filter media and regeneration technologies to maintain high performance. Recent technological innovations combine enhanced substrate materials and electronic monitoring systems, boosting overall emission control by integrating catalytic conversion with particulate filtration for comprehensive pollution reduction.

Future Trends: Enhancing Converter and DPF Performance

Advancements in catalytic converter efficiency are focusing on nanostructured catalysts and temperature-resistant materials to improve the reduction of nitrogen oxides and hydrocarbons. Diesel particulate filters (DPFs) are evolving with enhanced filtration media and regeneration techniques to capture ultrafine soot particles more effectively while reducing backpressure. Future trends emphasize integrating smart sensors and real-time monitoring systems to optimize the synergy between catalytic converters and DPFs, significantly lowering emissions in diesel engines.

Catalytic Converter Efficiency vs Diesel Particulate Filter Performance Infographic

cardiffo.com

cardiffo.com