Gasoline Direct Injection (GDI) engines typically produce higher particulate emissions compared to Port Fuel Injection (PFI) engines due to the direct spray of fuel into the combustion chamber, which can lead to incomplete combustion and increased soot formation. PFI engines generally emit lower particulate matter but may release higher levels of carbon monoxide and unburned hydrocarbons because of less precise fuel-air mixture control. Advances in GDI technology and after-treatment systems aim to reduce particulate emissions while maintaining fuel efficiency and performance advantages over PFI systems.

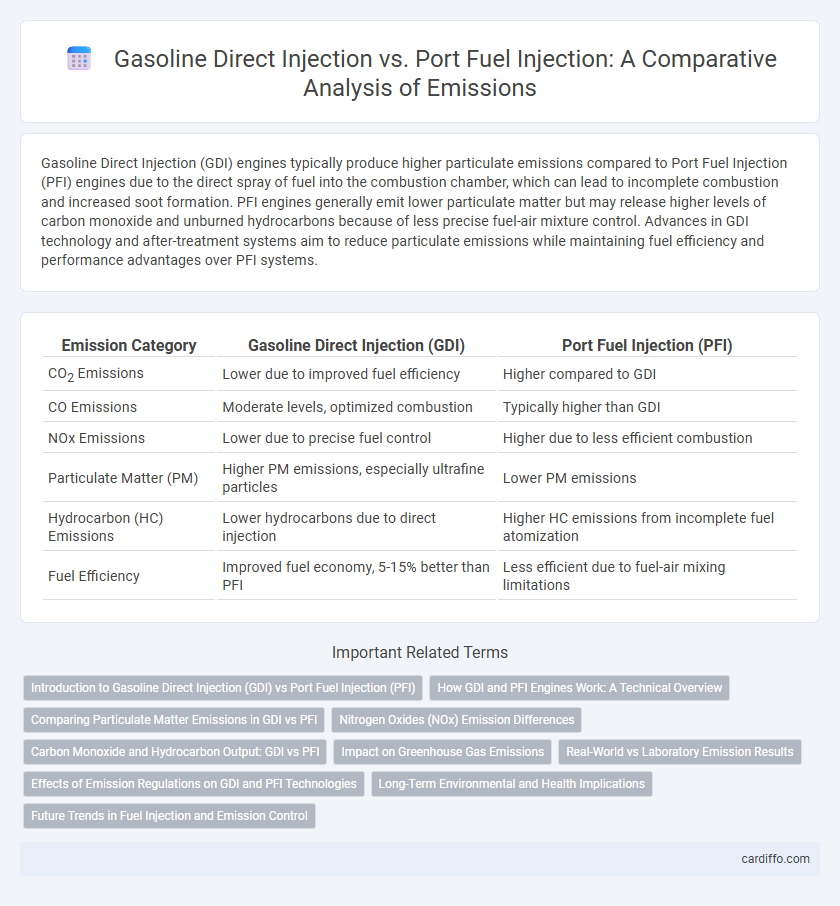

Table of Comparison

| Emission Category | Gasoline Direct Injection (GDI) | Port Fuel Injection (PFI) |

|---|---|---|

| CO2 Emissions | Lower due to improved fuel efficiency | Higher compared to GDI |

| CO Emissions | Moderate levels, optimized combustion | Typically higher than GDI |

| NOx Emissions | Lower due to precise fuel control | Higher due to less efficient combustion |

| Particulate Matter (PM) | Higher PM emissions, especially ultrafine particles | Lower PM emissions |

| Hydrocarbon (HC) Emissions | Lower hydrocarbons due to direct injection | Higher HC emissions from incomplete fuel atomization |

| Fuel Efficiency | Improved fuel economy, 5-15% better than PFI | Less efficient due to fuel-air mixing limitations |

Introduction to Gasoline Direct Injection (GDI) vs Port Fuel Injection (PFI)

Gasoline Direct Injection (GDI) delivers fuel directly into the combustion chamber, resulting in improved fuel atomization and higher combustion efficiency compared to Port Fuel Injection (PFI), which injects fuel into the intake port. GDI systems typically produce lower carbon dioxide (CO2) emissions due to better fuel economy but may increase particulate matter (PM) and nitrogen oxides (NOx) emissions relative to PFI. Understanding these distinctions is crucial for optimizing engine performance and meeting evolving emission standards.

How GDI and PFI Engines Work: A Technical Overview

Gasoline Direct Injection (GDI) engines inject fuel directly into the combustion chamber, allowing for precise fuel delivery and improved combustion efficiency, which often results in higher power output and better fuel economy. Port Fuel Injection (PFI) engines spray fuel into the intake manifold where it mixes with air before entering the combustion chamber, promoting more homogeneous air-fuel mixtures that can reduce certain particulate emissions but may lower overall efficiency compared to GDI systems. The distinct fuel delivery mechanisms in GDI and PFI engines influence emission profiles, with GDI typically producing higher particulate matter due to fuel spray atomization, while PFI shows advantages in minimizing hydrocarbon and carbon monoxide pollutants.

Comparing Particulate Matter Emissions in GDI vs PFI

Gasoline Direct Injection (GDI) engines produce significantly higher particulate matter (PM) emissions compared to Port Fuel Injection (PFI) systems due to the direct spray of fuel into the combustion chamber, which leads to incomplete fuel atomization and increased soot formation. Studies indicate that GDI engines can emit up to 10 times more PM than PFI engines, contributing to elevated urban air pollution and health risks. Efforts to reduce PM emissions from GDI engines focus on advanced fuel injection strategies and particulate filters to meet stricter emission standards.

Nitrogen Oxides (NOx) Emission Differences

Gasoline Direct Injection (GDI) engines typically produce higher Nitrogen Oxides (NOx) emissions compared to Port Fuel Injection (PFI) engines due to higher combustion temperatures and localized lean zones within the combustion chamber. The stratified charge and precise fuel delivery in GDI systems contribute to increased formation of NOx during combustion. Advanced aftertreatment systems and combustion strategies are essential to mitigate NOx emissions in GDI engines to meet stringent emission standards.

Carbon Monoxide and Hydrocarbon Output: GDI vs PFI

Gasoline Direct Injection (GDI) engines typically produce lower carbon monoxide (CO) emissions compared to Port Fuel Injection (PFI) systems due to more precise fuel delivery and improved combustion efficiency. However, GDI engines often emit higher levels of hydrocarbons (HC), especially particulate-bound HC, resulting from incomplete fuel vaporization in the combustion chamber. Studies indicate that while GDI reduces CO output by up to 30%, HC emissions can increase by approximately 20-40% relative to PFI engines under similar operating conditions.

Impact on Greenhouse Gas Emissions

Gasoline Direct Injection (GDI) engines typically produce lower carbon dioxide (CO2) emissions compared to Port Fuel Injection (PFI) engines due to more precise fuel delivery and improved combustion efficiency. However, GDI systems often emit higher levels of particulate matter (PM) and nitrogen oxides (NOx), which contribute significantly to air pollution and have indirect effects on greenhouse gas forcing. PFI engines, while generally emitting higher CO2, tend to produce fewer particulates and NOx, resulting in a different overall environmental impact profile regarding greenhouse gas emissions.

Real-World vs Laboratory Emission Results

Gasoline Direct Injection (GDI) engines typically exhibit higher real-world particulate matter (PM) emissions compared to Port Fuel Injection (PFI) systems, despite laboratory tests often showing lower nitrogen oxides (NOx) and carbon monoxide (CO) emissions for GDI. Real-world driving conditions reveal that GDI engines produce significantly more ultrafine particles due to incomplete fuel atomization and wall wetting, which are less detectable during standardized lab testing cycles. Portable Emission Measurement Systems (PEMS) have highlighted these discrepancies, emphasizing the need for updated regulatory protocols to address real-world particulate emissions from GDI vehicles.

Effects of Emission Regulations on GDI and PFI Technologies

Emission regulations have driven significant advancements in both Gasoline Direct Injection (GDI) and Port Fuel Injection (PFI) technologies, aiming to reduce particulate matter and nitrogen oxides (NOx) emissions. Stricter standards have prompted GDI systems to incorporate enhanced particulate filters and improved combustion control to meet low emission targets, while PFI engines benefit from their inherently lower particulate emissions but face challenges in optimizing fuel efficiency under new regulatory frameworks. Regulatory pressure encourages ongoing innovation in injection timing, fuel atomization, and emission after-treatment systems to minimize environmental impact and comply with tightening emission limits.

Long-Term Environmental and Health Implications

Gasoline Direct Injection (GDI) engines typically produce higher levels of particulate matter (PM) and nitrogen oxides (NOx) compared to Port Fuel Injection (PFI) systems, contributing to increased respiratory and cardiovascular health risks over time. Long-term exposure to GDI emissions is linked to elevated incidences of asthma, chronic bronchitis, and other pulmonary diseases due to finer PM size and higher NOx concentrations. In contrast, PFI engines emit lower PM but generally higher carbon monoxide, presenting a different but comparatively reduced long-term environmental and health burden.

Future Trends in Fuel Injection and Emission Control

Gasoline Direct Injection (GDI) emissions typically contain higher levels of particulate matter compared to Port Fuel Injection (PFI), prompting innovation in filtration and combustion control technologies. Future trends emphasize integrating advanced gasoline particulate filters (GPFs) with hybrid systems to reduce both carbon dioxide and particulate emissions. Emerging fuel injection strategies, combined with real-time emission monitoring and adaptive engine controls, aim to meet stricter global emission standards while enhancing fuel efficiency.

Gasoline Direct Injection Emissions vs Port Fuel Injection Emissions Infographic

cardiffo.com

cardiffo.com