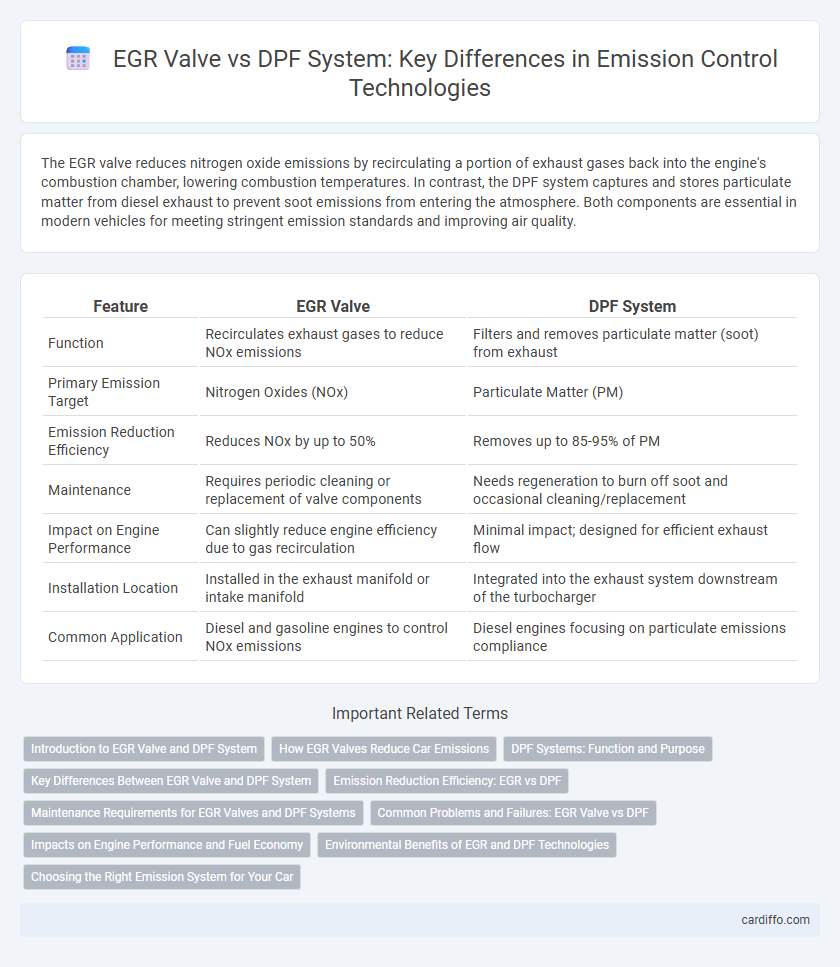

The EGR valve reduces nitrogen oxide emissions by recirculating a portion of exhaust gases back into the engine's combustion chamber, lowering combustion temperatures. In contrast, the DPF system captures and stores particulate matter from diesel exhaust to prevent soot emissions from entering the atmosphere. Both components are essential in modern vehicles for meeting stringent emission standards and improving air quality.

Table of Comparison

| Feature | EGR Valve | DPF System |

|---|---|---|

| Function | Recirculates exhaust gases to reduce NOx emissions | Filters and removes particulate matter (soot) from exhaust |

| Primary Emission Target | Nitrogen Oxides (NOx) | Particulate Matter (PM) |

| Emission Reduction Efficiency | Reduces NOx by up to 50% | Removes up to 85-95% of PM |

| Maintenance | Requires periodic cleaning or replacement of valve components | Needs regeneration to burn off soot and occasional cleaning/replacement |

| Impact on Engine Performance | Can slightly reduce engine efficiency due to gas recirculation | Minimal impact; designed for efficient exhaust flow |

| Installation Location | Installed in the exhaust manifold or intake manifold | Integrated into the exhaust system downstream of the turbocharger |

| Common Application | Diesel and gasoline engines to control NOx emissions | Diesel engines focusing on particulate emissions compliance |

Introduction to EGR Valve and DPF System

The Exhaust Gas Recirculation (EGR) valve reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine cylinders, lowering combustion temperature. The Diesel Particulate Filter (DPF) system captures and stores soot particles from diesel engine exhaust, preventing particulate matter from being released into the atmosphere. Both technologies play crucial roles in meeting stringent emission standards and improving air quality through targeted exhaust gas treatment.

How EGR Valves Reduce Car Emissions

EGR valves reduce car emissions by recirculating a portion of the exhaust gases back into the engine's combustion chamber, lowering combustion temperatures and reducing the formation of nitrogen oxides (NOx). This process decreases the amount of harmful pollutants released into the atmosphere, improving overall emission control. Unlike Diesel Particulate Filters (DPF) that trap particulate matter, EGR valves specifically target NOx emissions, contributing to cleaner exhaust gases.

DPF Systems: Function and Purpose

DPF systems trap and remove particulate matter from diesel exhaust gases, significantly reducing harmful emissions. These filters capture soot particles and periodically regenerate by burning off accumulated ash to maintain efficiency. By lowering particulate emissions, DPF systems help vehicles comply with stringent environmental regulations and improve air quality.

Key Differences Between EGR Valve and DPF System

The EGR (Exhaust Gas Recirculation) valve reduces nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the engine's intake, lowering combustion temperatures. In contrast, the DPF (Diesel Particulate Filter) system captures and removes particulate matter (soot) from diesel engine exhaust, preventing it from entering the atmosphere. While the EGR valve targets gaseous pollutants, the DPF system primarily addresses solid particulate emissions, making them complementary components in modern emission control strategies.

Emission Reduction Efficiency: EGR vs DPF

EGR valves reduce nitrogen oxide (NOx) emissions by recirculating exhaust gases into the combustion chamber, lowering combustion temperatures and thus decreasing NOx formation. DPF systems focus on capturing and oxidizing particulate matter (PM) from diesel exhaust, significantly reducing soot emissions that contribute to air pollution. While EGR targets gaseous emissions like NOx effectively, DPF excels in minimizing solid particle emissions, making them complementary technologies for comprehensive emission reduction.

Maintenance Requirements for EGR Valves and DPF Systems

EGR valves require regular cleaning to prevent carbon buildup that can lead to reduced engine performance and increased emissions, typically every 30,000 to 50,000 miles depending on driving conditions. DPF systems demand periodic regeneration cycles to burn off accumulated soot, with some vehicles needing manual intervention or additive refills to maintain filter efficiency. Neglecting maintenance in either EGR valves or DPF systems results in higher emissions, potential engine damage, and costly repairs.

Common Problems and Failures: EGR Valve vs DPF

EGR valves often face issues such as clogging from carbon deposits, leading to reduced engine performance and increased emissions. DPF systems commonly encounter problems like soot buildup, causing blockages that trigger regeneration cycles and potential engine warning lights. Both components require regular maintenance to prevent failures that can compromise emission control and vehicle efficiency.

Impacts on Engine Performance and Fuel Economy

EGR valves reduce nitrogen oxide emissions by recirculating exhaust gases into the combustion chamber, which can slightly lower engine power and fuel efficiency due to cooler combustion temperatures. DPF systems capture and burn soot particles from exhaust, maintaining emission standards but may cause increased backpressure, potentially reducing engine performance and increasing fuel consumption. Balancing EGR and DPF functionality is crucial for optimizing both emissions control and maintaining fuel economy in modern diesel engines.

Environmental Benefits of EGR and DPF Technologies

EGR valves reduce nitrogen oxide (NOx) emissions by recirculating a portion of exhaust gases back into the combustion chamber, lowering combustion temperatures and preventing the formation of harmful pollutants. DPF systems capture and oxidize particulate matter (PM) in diesel exhaust, significantly decreasing soot and fine particle emissions that contribute to air pollution and respiratory issues. Both technologies are critical for compliance with stringent emission regulations and play complementary roles in improving air quality and reducing environmental impact from diesel engines.

Choosing the Right Emission System for Your Car

Selecting the appropriate emission system depends on your vehicle's engine type and driving conditions, with EGR valves effectively reducing nitrogen oxide emissions by recirculating exhaust gases in gasoline and diesel engines. Diesel Particulate Filters (DPF) are essential for diesel engines, capturing soot and particulate matter to meet stringent emission standards. Evaluating your car's emission needs and maintenance preferences ensures optimal performance and compliance with environmental regulations.

EGR Valve vs DPF System Infographic

cardiffo.com

cardiffo.com