OBD emission tests monitor a vehicle's onboard diagnostic system to detect emission-related malfunctions in real-time, offering a quick and cost-effective assessment of pollution control systems. Chassis dynamometer tests measure exhaust emissions under simulated driving conditions, providing a comprehensive evaluation of a vehicle's overall emissions performance and fuel efficiency. Both methods play crucial roles in ensuring vehicles comply with environmental standards and reduce harmful air pollutants.

Table of Comparison

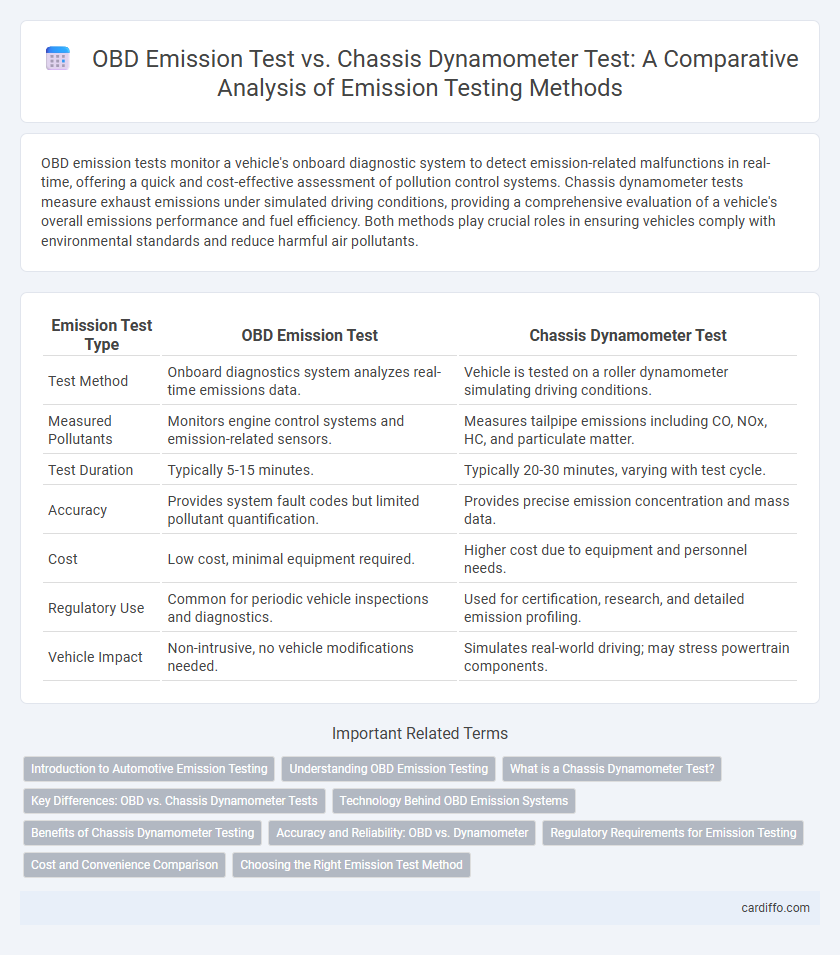

| Emission Test Type | OBD Emission Test | Chassis Dynamometer Test |

|---|---|---|

| Test Method | Onboard diagnostics system analyzes real-time emissions data. | Vehicle is tested on a roller dynamometer simulating driving conditions. |

| Measured Pollutants | Monitors engine control systems and emission-related sensors. | Measures tailpipe emissions including CO, NOx, HC, and particulate matter. |

| Test Duration | Typically 5-15 minutes. | Typically 20-30 minutes, varying with test cycle. |

| Accuracy | Provides system fault codes but limited pollutant quantification. | Provides precise emission concentration and mass data. |

| Cost | Low cost, minimal equipment required. | Higher cost due to equipment and personnel needs. |

| Regulatory Use | Common for periodic vehicle inspections and diagnostics. | Used for certification, research, and detailed emission profiling. |

| Vehicle Impact | Non-intrusive, no vehicle modifications needed. | Simulates real-world driving; may stress powertrain components. |

Introduction to Automotive Emission Testing

Automotive emission testing evaluates vehicle pollutants to ensure compliance with environmental regulations, with OBD emission tests monitoring the onboard diagnostics system for real-time emissions control. Chassis dynamometer tests measure exhaust gases under simulated driving conditions, providing precise quantification of pollutants like NOx, CO, and hydrocarbons. Both methods are essential for comprehensive emission assessments, supporting efforts to reduce air pollution and improve air quality.

Understanding OBD Emission Testing

On-Board Diagnostics (OBD) emission testing monitors a vehicle's emission control system by reading data from the vehicle's computer to detect malfunctions that impact emissions. Unlike chassis dynamometer tests, which physically measure exhaust gases under simulated driving conditions, OBD testing evaluates system readiness and sensor performance in real-time. This method provides a quicker, more cost-effective way to ensure compliance with emission standards and identify issues before they lead to higher pollutant outputs.

What is a Chassis Dynamometer Test?

A Chassis Dynamometer Test measures vehicle emissions by simulating real-world driving conditions while the vehicle remains stationary on rollers. This test evaluates the exhaust output of the entire vehicle, including the engine, transmission, and emission control systems under various speeds and loads. It provides comprehensive data on pollutants like CO, NOx, and hydrocarbons, offering a detailed assessment beyond standard OBD emission tests.

Key Differences: OBD vs. Chassis Dynamometer Tests

OBD emission tests analyze real-time data directly from a vehicle's onboard diagnostic system, detecting malfunctions in emission control components, while chassis dynamometer tests measure actual tailpipe emissions under simulated driving conditions on a test rig. OBD tests are faster, less expensive, and identify specific system faults, whereas chassis dynamometer tests provide comprehensive measurement of pollutants like CO, NOx, and HC emissions across various driving cycles. Emission regulations increasingly rely on OBD for routine screening, but chassis dynamometer testing remains essential for in-depth evaluations and regulatory compliance verification.

Technology Behind OBD Emission Systems

OBD emission systems rely on onboard sensors and diagnostic modules to continuously monitor vehicle emissions and engine performance in real-time, detecting pollutants like hydrocarbons, carbon monoxide, and nitrogen oxides. This technology utilizes data from the engine control unit (ECU) to identify malfunctions affecting emission control components, enabling immediate alerts and ensuring compliance with emission standards. In contrast, chassis dynamometer tests measure exhaust gases physically under controlled conditions, providing a direct but less continuous assessment of a vehicle's pollution output.

Benefits of Chassis Dynamometer Testing

Chassis dynamometer testing offers precise emission measurement by simulating real-world driving conditions, capturing comprehensive data across various engine loads and speeds that OBD emission tests might miss. This method detects transient emissions and fuel consumption more accurately, ensuring compliance with stricter environmental standards. Enhanced diagnostics through chassis dynamometer tests reduce false negatives, improving overall vehicle emission control and air quality management.

Accuracy and Reliability: OBD vs. Dynamometer

OBD emission tests offer precise real-time monitoring of a vehicle's onboard systems, ensuring accurate detection of emissions-related faults and compliance with regulations. Chassis dynamometer tests provide reliable measurements of actual tailpipe emissions under simulated driving conditions, capturing comprehensive pollutant data across various speeds and loads. While OBD tests excel in identifying malfunctions quickly, dynamometer tests deliver more exact emissions quantification, making both methods complementary for comprehensive emission evaluation.

Regulatory Requirements for Emission Testing

OBD emission tests are mandated by regulatory agencies such as the EPA and CARB to monitor real-time vehicle emissions and ensure compliance with set emission standards throughout the vehicle's operational life. Chassis dynamometer tests are required under regulations to measure exhaust emissions under controlled driving conditions, simulating real-world performance for pollutants like CO, NOx, and particulate matter. Regulatory frameworks prioritize OBD systems for continuous onboard monitoring, while dynamometer tests provide comprehensive emissions data for certification and compliance verification.

Cost and Convenience Comparison

OBD emission tests are generally more cost-effective and convenient, requiring only a vehicle's onboard diagnostics system to evaluate emissions, which reduces the need for specialized equipment. Chassis dynamometer tests involve expensive machinery and longer setup times, increasing overall testing costs and complexity. The OBD test's quick, less resource-intensive process provides significant savings for both testing facilities and vehicle owners.

Choosing the Right Emission Test Method

Choosing the right emission test method depends on the vehicle type and regulatory requirements. OBD emission tests monitor real-time data directly from the vehicle's engine control unit, offering quick diagnostics for modern cars. Chassis dynamometer tests simulate real driving conditions by measuring exhaust emissions under various loads, providing comprehensive data but requiring specialized equipment and testing facilities.

OBD emission test vs Chassis dynamometer test Infographic

cardiffo.com

cardiffo.com