Selective Catalytic Reduction (SCR) reduces nitrogen oxide emissions by injecting a urea-based solution into exhaust gases, converting harmful NOx into harmless nitrogen and water. Exhaust Gas Recirculation (EGR) lowers NOx by recirculating a portion of exhaust gases into the combustion chamber, reducing combustion temperature. SCR generally achieves higher NOx reduction efficiency, while EGR offers simpler integration but may increase particulate emissions.

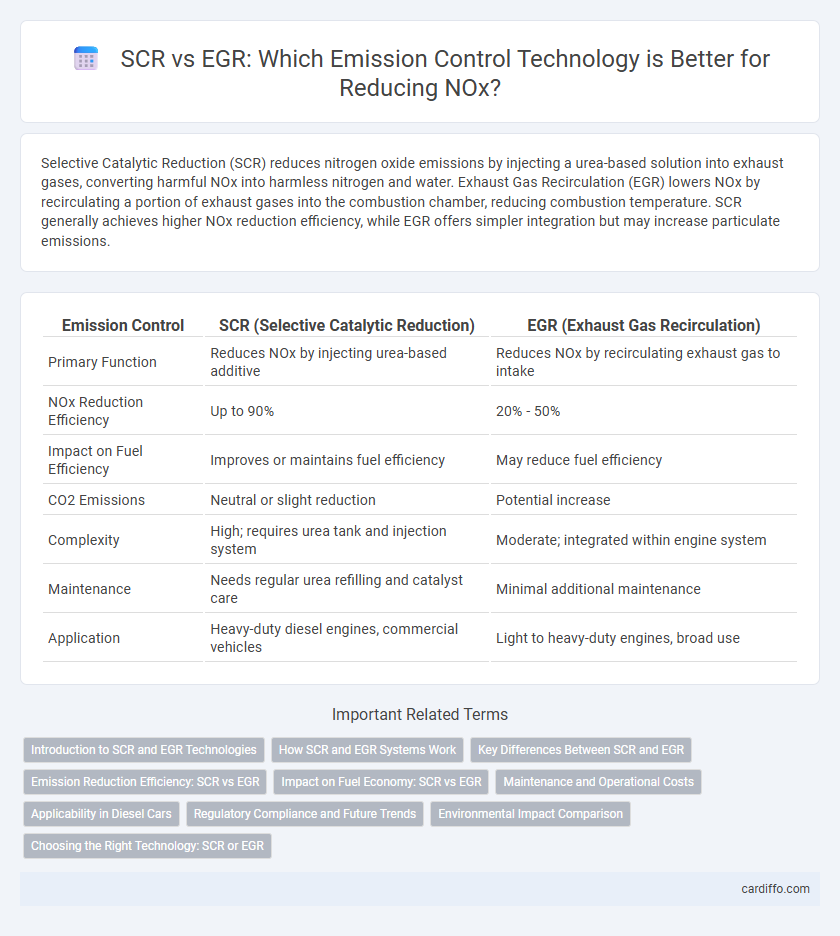

Table of Comparison

| Emission Control | SCR (Selective Catalytic Reduction) | EGR (Exhaust Gas Recirculation) |

|---|---|---|

| Primary Function | Reduces NOx by injecting urea-based additive | Reduces NOx by recirculating exhaust gas to intake |

| NOx Reduction Efficiency | Up to 90% | 20% - 50% |

| Impact on Fuel Efficiency | Improves or maintains fuel efficiency | May reduce fuel efficiency |

| CO2 Emissions | Neutral or slight reduction | Potential increase |

| Complexity | High; requires urea tank and injection system | Moderate; integrated within engine system |

| Maintenance | Needs regular urea refilling and catalyst care | Minimal additional maintenance |

| Application | Heavy-duty diesel engines, commercial vehicles | Light to heavy-duty engines, broad use |

Introduction to SCR and EGR Technologies

Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) are advanced emission control technologies primarily used to reduce nitrogen oxides (NOx) in diesel engines. SCR systems inject urea-based diesel exhaust fluid into the exhaust stream, converting NOx into nitrogen and water through a catalytic reaction. EGR recirculates a portion of exhaust gases back into the combustion chamber, lowering combustion temperatures and thereby reducing NOx formation at the source.

How SCR and EGR Systems Work

Selective Catalytic Reduction (SCR) reduces nitrogen oxides (NOx) by injecting a urea-based solution into exhaust gases, converting NOx into harmless nitrogen and water through a catalytic process. Exhaust Gas Recirculation (EGR) lowers combustion temperatures by recirculating a portion of exhaust gases back into the engine's intake, decreasing NOx formation at the source. SCR systems target post-combustion emission treatment, while EGR modifies combustion chemistry to minimize pollutant generation.

Key Differences Between SCR and EGR

Selective Catalytic Reduction (SCR) reduces nitrogen oxide (NOx) emissions by injecting a urea-based solution into exhaust gases, converting harmful NOx into nitrogen and water through a catalytic reaction. Exhaust Gas Recirculation (EGR) lowers NOx formation by recirculating a portion of the exhaust gas back into the engine cylinders, reducing combustion temperature and oxygen availability. SCR is external to the engine and more effective at high-load conditions, while EGR is integrated within the engine and primarily reduces NOx during low to medium engine loads.

Emission Reduction Efficiency: SCR vs EGR

Selective Catalytic Reduction (SCR) achieves higher emission reduction efficiency by converting up to 90% of nitrogen oxides (NOx) into harmless nitrogen and water using a urea-based reductant. Exhaust Gas Recirculation (EGR) lowers NOx emissions by recirculating a portion of exhaust gases back into the engine combustion chamber, typically reducing NOx by 20-50%, which is less effective than SCR systems. SCR systems are widely preferred in heavy-duty diesel engines for superior NOx control and compliance with stringent emission standards such as Euro VI and EPA Tier 4.

Impact on Fuel Economy: SCR vs EGR

Selective Catalytic Reduction (SCR) systems improve fuel economy by optimizing combustion efficiency and reducing fuel consumption through precise control of nitrogen oxides (NOx) emissions. Exhaust Gas Recirculation (EGR) often decreases fuel economy because it recirculates exhaust gases, reducing combustion temperature and engine efficiency. Studies indicate SCR-equipped vehicles typically achieve better miles per gallon (MPG) compared to those using EGR technology.

Maintenance and Operational Costs

Selective Catalytic Reduction (SCR) systems incur higher initial installation and reagent costs but typically offer lower maintenance expenses due to fewer component wear issues compared to Exhaust Gas Recirculation (EGR) systems. EGR systems require frequent cleaning and replacement of valves and coolers due to soot and particulate buildup, increasing operational downtime and labor costs. Over the long term, SCR's need for urea replenishment is offset by reduced engine efficiency losses and lower maintenance frequency, making it more cost-effective in high-mileage applications.

Applicability in Diesel Cars

Selective Catalytic Reduction (SCR) systems effectively reduce nitrogen oxide (NOx) emissions in diesel cars by injecting a urea-based solution into the exhaust stream, making them highly applicable for vehicles with higher engine loads and long-distance driving. Exhaust Gas Recirculation (EGR) recirculates a portion of exhaust gases back into the engine cylinders, lowering combustion temperatures and NOx formation, which suits smaller, urban-focused diesel cars. SCR generally offers better NOx reduction efficiency and fuel economy improvement, while EGR is favored for cost-effectiveness and simplicity in lighter-duty diesel vehicles.

Regulatory Compliance and Future Trends

Selective Catalytic Reduction (SCR) technology consistently meets stringent emission standards by effectively reducing nitrogen oxides (NOx) through urea-based chemical reactions, positioning it as a preferred solution for regulatory compliance in heavy-duty vehicles. Exhaust Gas Recirculation (EGR) lowers NOx emissions by recirculating a portion of exhaust gas back into the engine, but faces limitations with increasingly strict future regulations targeting lower particulate matter and greenhouse gases. Emerging trends suggest a combined SCR-EGR approach supplemented by advanced sensors and AI for real-time emissions control, aligning with progressive governmental policies emphasizing zero-emission targets and sustainability.

Environmental Impact Comparison

Selective Catalytic Reduction (SCR) systems significantly reduce nitrogen oxide (NOx) emissions by converting them into nitrogen and water using ammonia, resulting in lower environmental pollution compared to Exhaust Gas Recirculation (EGR). EGR lowers NOx by recirculating a portion of exhaust gases back into the combustion chamber, which can increase particulate matter and carbon dioxide emissions, potentially impacting air quality and climate change more negatively. SCR's ability to achieve higher NOx reduction efficiency with lower secondary emissions makes it a more environmentally favorable technology in meeting stringent emission standards.

Choosing the Right Technology: SCR or EGR

Selective Catalytic Reduction (SCR) offers superior nitrogen oxide (NOx) reduction by injecting urea-based agents directly into exhaust streams, achieving up to 90% NOx reduction in heavy-duty vehicles. Exhaust Gas Recirculation (EGR) lowers combustion temperatures by recirculating a portion of exhaust gases back into the engine, reducing NOx emissions effectively at lower costs but with potential trade-offs in fuel efficiency. The choice between SCR and EGR depends on regulatory requirements, operational costs, and desired emission reduction levels for diesel engines.

SCR vs EGR Infographic

cardiffo.com

cardiffo.com