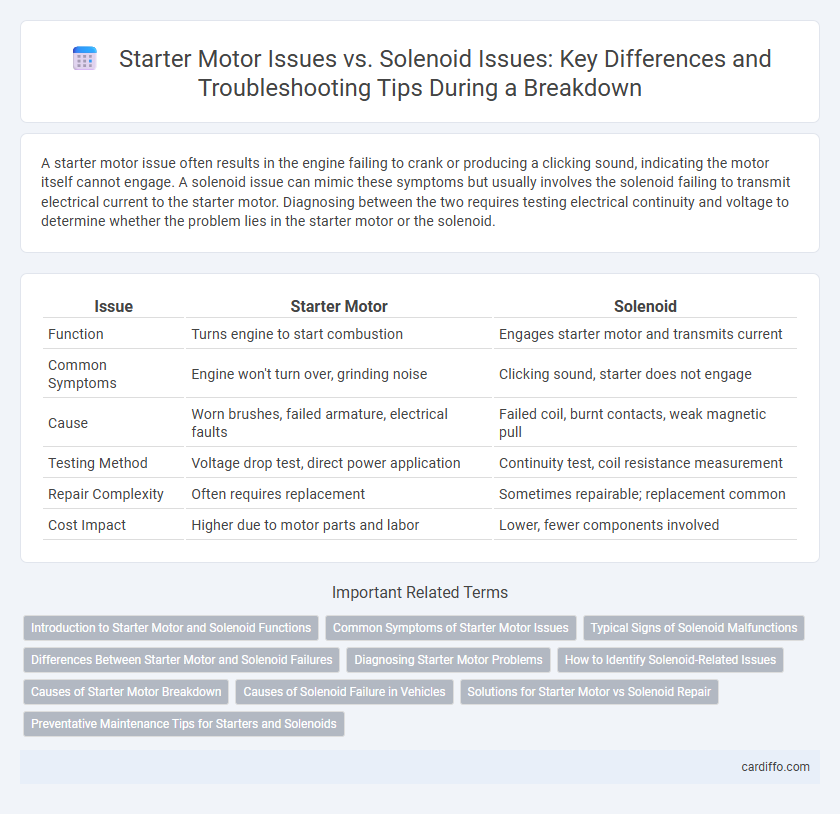

A starter motor issue often results in the engine failing to crank or producing a clicking sound, indicating the motor itself cannot engage. A solenoid issue can mimic these symptoms but usually involves the solenoid failing to transmit electrical current to the starter motor. Diagnosing between the two requires testing electrical continuity and voltage to determine whether the problem lies in the starter motor or the solenoid.

Table of Comparison

| Issue | Starter Motor | Solenoid |

|---|---|---|

| Function | Turns engine to start combustion | Engages starter motor and transmits current |

| Common Symptoms | Engine won't turn over, grinding noise | Clicking sound, starter does not engage |

| Cause | Worn brushes, failed armature, electrical faults | Failed coil, burnt contacts, weak magnetic pull |

| Testing Method | Voltage drop test, direct power application | Continuity test, coil resistance measurement |

| Repair Complexity | Often requires replacement | Sometimes repairable; replacement common |

| Cost Impact | Higher due to motor parts and labor | Lower, fewer components involved |

Introduction to Starter Motor and Solenoid Functions

The starter motor is responsible for cranking the engine by converting electrical energy into mechanical motion, initiating the combustion process. The solenoid acts as an electromagnetic switch that engages the starter motor's drive gear with the engine's flywheel, enabling power transfer. Proper functioning of both components is essential for reliable engine startup and avoiding breakdowns.

Common Symptoms of Starter Motor Issues

Common symptoms of starter motor issues include a clicking sound when turning the key, a slow or labored engine crank, and complete failure to start the engine despite a fully charged battery. Unlike solenoid problems, which often produce intermittent starting and electrical clicking noises, starter motor faults typically result in a consistent inability to engage the engine's flywheel. Diagnosing starter motor issues involves checking for voltage drop, worn brushes, or a faulty armature that disrupts power delivery during engine startup.

Typical Signs of Solenoid Malfunctions

Typical signs of solenoid malfunctions include a clicking sound when turning the key, failure of the starter motor to engage, and intermittent starting problems. A faulty solenoid may cause electrical connection issues, preventing power from reaching the starter motor despite a fully charged battery. Unlike starter motor failures, solenoid problems often manifest as sudden loss of electrical engagement without mechanical grinding or spinning noises.

Differences Between Starter Motor and Solenoid Failures

Starter motor failures typically present symptoms such as a complete lack of engine crank despite battery power, often due to internal mechanical wear or electrical faults within the motor itself. Solenoid failures, on the other hand, usually result in a clicking sound without engine turnover, caused by the solenoid's inability to engage the starter motor properly. Diagnosing whether the fault lies with the starter motor or the solenoid requires testing voltage continuity and mechanical engagement to pinpoint the exact source of starting issues.

Diagnosing Starter Motor Problems

Diagnosing starter motor problems requires distinguishing between starter motor issues and solenoid failures, as both impact engine ignition but exhibit different symptoms. A faulty starter motor often results in a clicking sound without engine turnover, while a solenoid issue may produce a single click or no sound at all, indicating electrical circuit problems. Testing voltage at the solenoid terminals and checking for continuity can accurately identify the root cause, ensuring targeted repairs or necessary starter motor replacements.

How to Identify Solenoid-Related Issues

Solenoid-related issues in a breakdown often manifest as a clicking sound when turning the key without the engine starting, indicating the solenoid fails to engage the starter motor properly. To identify solenoid problems, test for voltage at the solenoid terminals and check for continuity using a multimeter, ensuring the solenoid receives power but does not transmit it to the starter motor. Visual inspection for corrosion or loose connections around the solenoid also helps distinguish solenoid failures from starter motor issues, guiding accurate diagnosis.

Causes of Starter Motor Breakdown

Starter motor breakdown often results from electrical faults such as worn brushes, damaged armature, or a faulty commutator that impede the motor's function. Solenoid issues typically arise from coil failure, stuck plunger, or corroded contacts, which prevent engaging the starter motor properly. Identifying the root cause requires testing both the starter motor's mechanical components and the solenoid's electrical continuity for effective repair.

Causes of Solenoid Failure in Vehicles

Solenoid failure in vehicles commonly results from electrical issues like corroded terminals or a weak battery, preventing proper activation of the starter motor. Mechanical wear within the solenoid, such as damaged plunger springs or burnt contacts, also contributes to malfunction. Exposure to dirt, moisture, and extreme temperatures further accelerates solenoid deterioration, leading to breakdown and starter motor failure.

Solutions for Starter Motor vs Solenoid Repair

Starter motor issues typically require checking the motor's brushes, armature, and commutator for wear or damage, often necessitating replacement or professional rewinding to restore functionality. Solenoid problems usually involve faulty electrical connections or a burnt coil, which can be resolved by cleaning terminals or replacing the solenoid assembly. Accurate diagnosis between starter motor and solenoid faults ensures targeted repairs, minimizing downtime and repair costs.

Preventative Maintenance Tips for Starters and Solenoids

Regular inspection and cleaning of starter motor terminals and solenoid contacts prevent corrosion and ensure reliable electrical connections. Applying dielectric grease to solenoid terminals reduces moisture buildup and helps avoid premature failure. Testing starter torque and solenoid engagement during routine vehicle maintenance detects early wear and prevents sudden breakdowns.

Starter motor issue vs solenoid issue Infographic

cardiffo.com

cardiffo.com