Turbocharger failure often results from excessive heat and oil contamination, leading to reduced engine performance and increased emissions. Supercharger failure typically arises from belt slippage, worn bearings, or internal component damage, causing a noticeable drop in power and throttle response. Both failures demand prompt diagnosis and repair to prevent further engine damage and maintain optimal vehicle function.

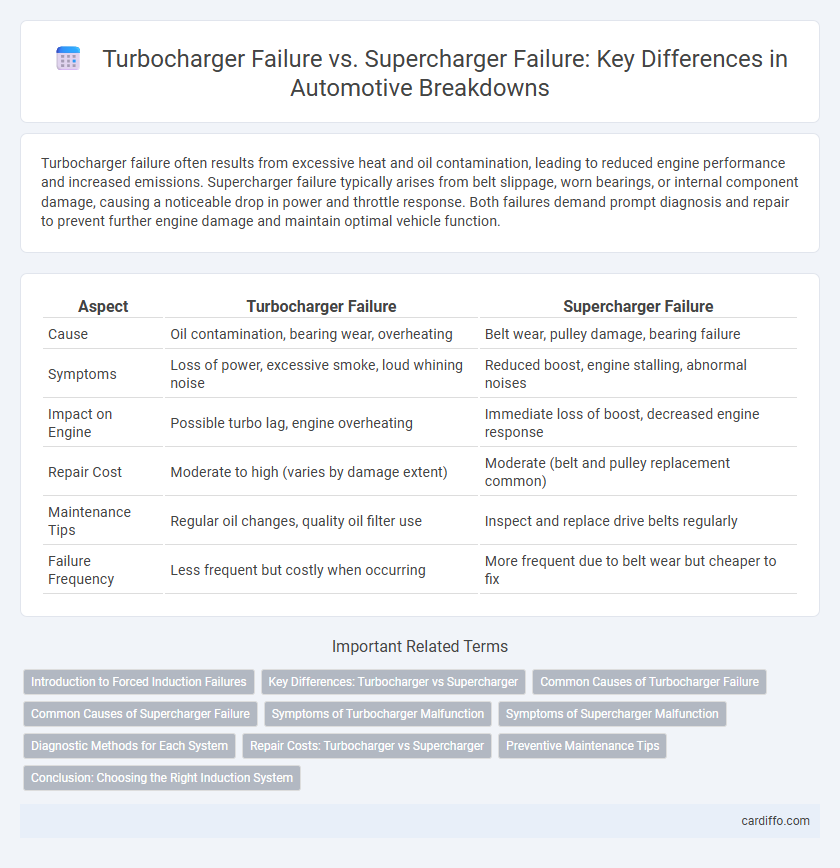

Table of Comparison

| Aspect | Turbocharger Failure | Supercharger Failure |

|---|---|---|

| Cause | Oil contamination, bearing wear, overheating | Belt wear, pulley damage, bearing failure |

| Symptoms | Loss of power, excessive smoke, loud whining noise | Reduced boost, engine stalling, abnormal noises |

| Impact on Engine | Possible turbo lag, engine overheating | Immediate loss of boost, decreased engine response |

| Repair Cost | Moderate to high (varies by damage extent) | Moderate (belt and pulley replacement common) |

| Maintenance Tips | Regular oil changes, quality oil filter use | Inspect and replace drive belts regularly |

| Failure Frequency | Less frequent but costly when occurring | More frequent due to belt wear but cheaper to fix |

Introduction to Forced Induction Failures

Turbocharger failure typically results from excessive heat and inadequate lubrication, causing turbine damage and reduced boost pressure, while supercharger failure often stems from belt wear or mechanical stress leading to loss of drive and insufficient air compression. Both forced induction failures impact engine performance, fuel efficiency, and emissions by disrupting the forced air intake system. Understanding the distinct failure modes of turbochargers and superchargers is critical for diagnosing forced induction breakdowns and maintaining optimal engine function.

Key Differences: Turbocharger vs Supercharger

Turbocharger failure often results from excessive heat and oil supply issues, causing turbine damage and reduced boost pressure, whereas supercharger failure typically involves belt slippage or mechanical wear due to its direct connection to the engine crankshaft. Turbochargers rely on exhaust gases to spin the turbine, making them more susceptible to thermal stress, while superchargers provide immediate boost through a belt-driven compressor, leading to different failure modes. Understanding these distinct operational mechanisms is crucial for diagnosing and preventing breakdowns related to forced induction systems.

Common Causes of Turbocharger Failure

Common causes of turbocharger failure include oil contamination, insufficient lubrication, and excessive heat buildup, which damage the turbo's bearings and blades. Worn seals allow oil leaks, reducing efficiency and increasing the risk of engine damage. Debris ingestion and poor maintenance practices also significantly contribute to premature turbocharger breakdown.

Common Causes of Supercharger Failure

Common causes of supercharger failure include worn bearings, rotor damage, and oil starvation, which lead to decreased efficiency and potential engine damage. In contrast to turbochargers, superchargers rely on a direct belt-driven mechanism, making belt wear and misalignment critical factors in failure. Regular maintenance and proper lubrication are essential to prevent issues such as overheating and excessive wear in supercharger components.

Symptoms of Turbocharger Malfunction

Turbocharger failure symptoms include excessive exhaust smoke, reduced engine power, and unusual whining noises indicating bearing wear or shaft damage. A drop in boost pressure and increased oil consumption point to turbo seal leaks or compressor wheel damage. Unlike superchargers, turbo failures often produce delayed acceleration and visible smoke due to exhaust gas-driven mechanics.

Symptoms of Supercharger Malfunction

Symptoms of supercharger malfunction include reduced engine power, unusual whining or rattling noises from the engine bay, and excessive smoke from the exhaust. Drivers may also notice poor acceleration, engine misfires, or a decrease in fuel efficiency. These signs often indicate issues like a failing belt, damaged rotors, or oil contamination within the supercharger system.

Diagnostic Methods for Each System

Diagnostic methods for turbocharger failure often involve assessing boost pressure irregularities with a boost gauge, inspecting the turbine and compressor wheels for damage or excessive shaft play, and using a smoke test to detect oil leaks in the system. Supercharger failure diagnostics typically include checking belt tension and condition, measuring boost levels with a pressure sensor, and performing a visual inspection of the rotors for wear or damage. Both systems benefit from engine control unit (ECU) error code analysis to identify sensor malfunctions or airflow inconsistencies affecting forced induction performance.

Repair Costs: Turbocharger vs Supercharger

Turbocharger repair costs typically range from $1,000 to $2,500 due to their complex design and high-performance components. Supercharger repairs generally fall between $500 and $1,500, reflecting simpler mechanics and fewer parts. The higher cost of turbocharger repairs is often influenced by the need for specialized labor and replacement of costly turbines or intercoolers.

Preventive Maintenance Tips

Regular inspection of turbocharger bearings and oil supply system is vital to prevent turbocharger failure, as inadequate lubrication leads to overheating and wear. For superchargers, maintaining belt tension and checking for air leaks in the intake system helps avoid performance degradation and mechanical breakdowns. Implementing scheduled maintenance protocols, including cleaning and replacing filters, ensures optimal operation and extends the lifespan of both forced induction systems.

Conclusion: Choosing the Right Induction System

Turbocharger failure often results from high exhaust temperatures and turbine damage, whereas supercharger failure is linked to belt issues and mechanical wear. Selecting the right induction system depends on vehicle type, performance goals, and maintenance preferences. Turbochargers offer better fuel efficiency and power at high RPMs, while superchargers provide immediate boost and simpler mechanics.

Turbocharger failure vs supercharger failure Infographic

cardiffo.com

cardiffo.com