Starter motor failure prevents the engine from turning over due to a faulty electrical motor, often causing a clicking sound or complete silence when attempting to start the vehicle. Ignition switch failure disrupts the electrical connection needed to power the starter motor and accessories, resulting in the vehicle not starting or the dashboard lights failing to illuminate. Diagnosing the issue requires distinguishing between a dead starter motor and an unresponsive ignition switch to ensure accurate repairs and avoid unnecessary part replacements.

Table of Comparison

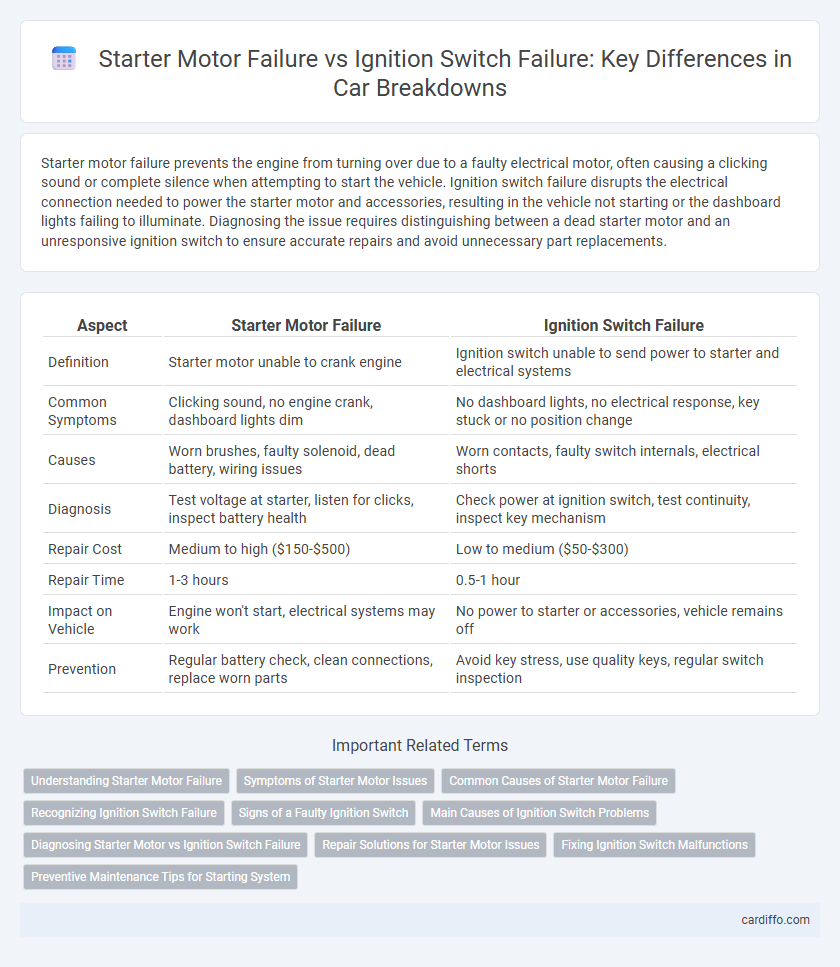

| Aspect | Starter Motor Failure | Ignition Switch Failure |

|---|---|---|

| Definition | Starter motor unable to crank engine | Ignition switch unable to send power to starter and electrical systems |

| Common Symptoms | Clicking sound, no engine crank, dashboard lights dim | No dashboard lights, no electrical response, key stuck or no position change |

| Causes | Worn brushes, faulty solenoid, dead battery, wiring issues | Worn contacts, faulty switch internals, electrical shorts |

| Diagnosis | Test voltage at starter, listen for clicks, inspect battery health | Check power at ignition switch, test continuity, inspect key mechanism |

| Repair Cost | Medium to high ($150-$500) | Low to medium ($50-$300) |

| Repair Time | 1-3 hours | 0.5-1 hour |

| Impact on Vehicle | Engine won't start, electrical systems may work | No power to starter or accessories, vehicle remains off |

| Prevention | Regular battery check, clean connections, replace worn parts | Avoid key stress, use quality keys, regular switch inspection |

Understanding Starter Motor Failure

Starter motor failure occurs when the electrical component responsible for cranking the engine does not engage or turn, often caused by worn brushes, a faulty solenoid, or poor electrical connections. Symptoms include a clicking noise when turning the key, no engine turnover, or intermittent starting issues, distinguishing it from ignition switch failure, which affects the electrical flow through the ignition circuit but may still allow dashboard lights to illuminate. Diagnosing starter motor failure requires checking battery voltage, solenoid function, and starter motor continuity to confirm the malfunction and rule out ignition-related problems.

Symptoms of Starter Motor Issues

Symptoms of starter motor failure include a clicking noise when turning the key, a slow or sluggish engine crank, and complete engine non-start. The starter motor may also produce a grinding sound or fail to engage the flywheel properly. These issues contrast with ignition switch failure, which often results in intermittent power loss or dashboard warning lights without the characteristic cranking problems.

Common Causes of Starter Motor Failure

Starter motor failure typically results from worn brushes, a faulty solenoid, or electrical issues such as corroded wiring or a dead battery. Mechanical problems like a seized motor or damaged pinion gear can also cause the starter to malfunction. Regular maintenance and timely inspection of these components help prevent sudden breakdowns caused by starter motor failure.

Recognizing Ignition Switch Failure

Recognizing ignition switch failure involves identifying symptoms such as dim dashboard lights, intermittent power loss, and inability to start the engine despite a fully charged battery. Unlike starter motor failure, which often produces a clicking noise or complete silence during ignition attempts, ignition switch problems disrupt electrical flow to multiple systems simultaneously. Diagnosing ignition switch issues early can prevent further electrical failures and costly repairs.

Signs of a Faulty Ignition Switch

Signs of a faulty ignition switch include difficulty turning the key, intermittent loss of electrical power, and the engine failing to start despite a fully charged battery. Flickering dashboard lights and the stalling of the engine while driving are also common indicators of ignition switch malfunction. Diagnosing these symptoms early can prevent complete breakdown and costly repairs.

Main Causes of Ignition Switch Problems

Ignition switch problems primarily arise from worn electrical contacts, corrosion, and mechanical wear due to frequent use or exposure to moisture. Faulty wiring and poor connections inside the ignition cylinder can disrupt power flow to the starter motor, causing engine starting failures. Over time, accumulation of dirt and debris inside the ignition switch also leads to intermittent or complete ignition failure, distinguishing it from typical starter motor breakdowns.

Diagnosing Starter Motor vs Ignition Switch Failure

Diagnosing starter motor failure versus ignition switch failure requires careful assessment of symptoms and tests. A faulty starter motor often results in a clicking noise or no response when turning the key, while ignition switch failure may cause electrical accessories to malfunction without starting the engine. Using a multimeter to check voltage at the starter and ignition switch continuity helps isolate the exact source of the breakdown.

Repair Solutions for Starter Motor Issues

Repair solutions for starter motor issues typically involve inspecting and replacing faulty components such as the solenoid, brushes, or armature. Cleaning corrosion from electrical connections and ensuring proper battery voltage can restore starter function effectively. In some cases, a complete starter motor replacement is necessary to resolve persistent failure symptoms.

Fixing Ignition Switch Malfunctions

Fixing ignition switch malfunctions involves diagnosing electrical faults that prevent the starter motor from receiving power, often requiring inspection of wiring and replacement of the switch itself. Unlike starter motor failure, which demands motor repair or replacement, ignition switch issues demand targeted attention to the electrical contacts and connections within the switch assembly. Proper repair restores the vehicle's ability to start without draining the battery or causing intermittent power loss.

Preventive Maintenance Tips for Starting System

Preventive maintenance for starting system issues emphasizes regular inspection of the starter motor and ignition switch to detect early signs of wear or corrosion. Cleaning connectors, tightening electrical connections, and testing voltage levels help prevent starter motor failure and ignition switch malfunction. Implementing scheduled lubrication and using dielectric grease on terminals can extend component lifespan and improve system reliability.

Starter motor failure vs ignition switch failure Infographic

cardiffo.com

cardiffo.com