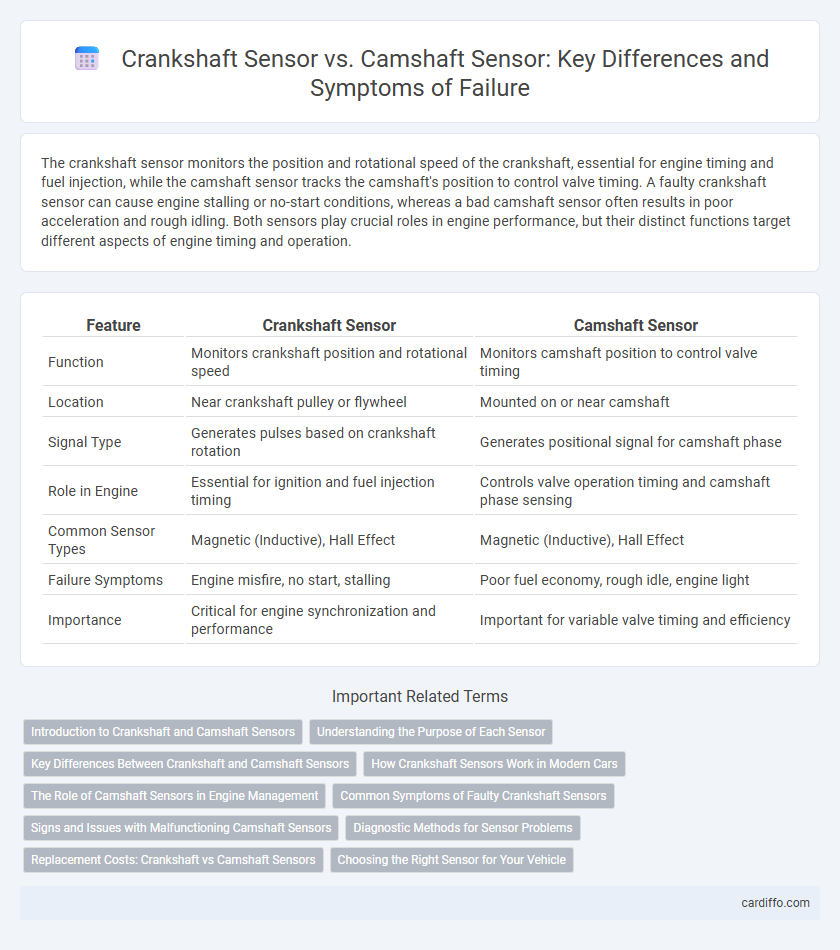

The crankshaft sensor monitors the position and rotational speed of the crankshaft, essential for engine timing and fuel injection, while the camshaft sensor tracks the camshaft's position to control valve timing. A faulty crankshaft sensor can cause engine stalling or no-start conditions, whereas a bad camshaft sensor often results in poor acceleration and rough idling. Both sensors play crucial roles in engine performance, but their distinct functions target different aspects of engine timing and operation.

Table of Comparison

| Feature | Crankshaft Sensor | Camshaft Sensor |

|---|---|---|

| Function | Monitors crankshaft position and rotational speed | Monitors camshaft position to control valve timing |

| Location | Near crankshaft pulley or flywheel | Mounted on or near camshaft |

| Signal Type | Generates pulses based on crankshaft rotation | Generates positional signal for camshaft phase |

| Role in Engine | Essential for ignition and fuel injection timing | Controls valve operation timing and camshaft phase sensing |

| Common Sensor Types | Magnetic (Inductive), Hall Effect | Magnetic (Inductive), Hall Effect |

| Failure Symptoms | Engine misfire, no start, stalling | Poor fuel economy, rough idle, engine light |

| Importance | Critical for engine synchronization and performance | Important for variable valve timing and efficiency |

Introduction to Crankshaft and Camshaft Sensors

Crankshaft sensors and camshaft sensors are critical components in modern engine management systems, providing real-time data on the position and rotational speed of the crankshaft and camshaft respectively. The crankshaft sensor monitors the crankshaft's rotation to control ignition timing, fuel injection, and engine synchronization, while the camshaft sensor tracks camshaft positioning to optimize valve timing and enhance engine performance. Accurate readings from both sensors ensure efficient engine operation, prevent misfires, and reduce emissions by coordinating fuel delivery and spark timing.

Understanding the Purpose of Each Sensor

Crankshaft sensors monitor the position and rotational speed of the crankshaft, providing critical data for engine timing and fuel injection control. Camshaft sensors track the position of the camshaft to synchronize the opening and closing of engine valves with piston movement. Together, these sensors ensure precise ignition timing and optimal engine performance by coordinating the engine's internal mechanical functions.

Key Differences Between Crankshaft and Camshaft Sensors

Crankshaft sensors monitor the position and rotational speed of the crankshaft to ensure precise ignition timing and fuel injection, while camshaft sensors track the camshaft's position to control valve timing and engine cycle phase. Crankshaft sensors typically produce signals based on a toothed wheel attached to the crankshaft, whereas camshaft sensors rely on a reluctor wheel or magnetic pickup. Accurate synchronization from both sensors is critical for engine performance and preventing breakdowns due to misfires or timing errors.

How Crankshaft Sensors Work in Modern Cars

Crankshaft sensors in modern cars use magnetic or Hall effect technology to monitor the position and rotational speed of the crankshaft, providing real-time data to the engine control unit (ECU) for precise ignition timing and fuel injection. This sensor generates electrical signals as the crankshaft rotates, allowing the ECU to synchronize engine functions and optimize performance. Accurate crankshaft sensor readings are essential for preventing engine misfires, stalling, and breakdowns.

The Role of Camshaft Sensors in Engine Management

Camshaft sensors monitor the position and rotational speed of the camshaft, providing critical data to the engine control unit (ECU) for precise fuel injection timing and ignition control. Accurate camshaft sensor signals ensure optimal valve timing, improving engine performance and fuel efficiency while reducing emissions. Malfunctioning camshaft sensors can lead to engine misfires, poor acceleration, and increased fuel consumption.

Common Symptoms of Faulty Crankshaft Sensors

Faulty crankshaft sensors commonly cause engine stalling, misfires, and difficulty starting due to inaccurate engine speed and position data. These symptoms arise because the sensor fails to send proper signals to the engine control unit, disrupting fuel injection and ignition timing. Unlike camshaft sensors, which primarily affect valve timing, crankshaft sensor issues directly impact overall engine performance and operation.

Signs and Issues with Malfunctioning Camshaft Sensors

Malfunctioning camshaft sensors often cause engine misfires, rough idling, and poor acceleration, indicating irregular timing signal data to the ECU. Common signs include difficulty starting the engine, stalling, and reduced fuel efficiency due to incorrect fuel injection timing. These sensor failures can trigger the check engine light and disrupt synchronization between the crankshaft and camshaft sensors, leading to engine breakdown.

Diagnostic Methods for Sensor Problems

Diagnostic methods for crankshaft and camshaft sensor problems commonly include using an OBD-II scanner to check for error codes related to sensor malfunctions. Technicians also measure sensor voltage and resistance with a multimeter to verify signal integrity and sensor functionality. Oscilloscope testing provides a detailed waveform analysis, identifying irregularities in sensor output signals crucial for accurate engine timing diagnosis.

Replacement Costs: Crankshaft vs Camshaft Sensors

Replacement costs for crankshaft sensors typically range from $100 to $250, including parts and labor, while camshaft sensor replacements usually cost between $120 and $300 due to differences in sensor complexity and vehicle accessibility. Crankshaft sensors are often less expensive to replace because they are more accessible and have simpler designs compared to camshaft sensors, which may require additional disassembly. Labor fees can significantly impact the total cost, especially if the camshaft sensor is located deep within the engine assembly.

Choosing the Right Sensor for Your Vehicle

Choosing the right sensor for your vehicle depends on the engine type and diagnostic requirements, as the crankshaft sensor monitors the position and rotational speed of the crankshaft to ensure optimal ignition timing, while the camshaft sensor tracks the camshaft's position to control fuel injection and valve timing. High-precision crankshaft sensors are essential for accurate engine timing and preventing breakdowns caused by misfires or poor performance. For vehicles with variable valve timing, a reliable camshaft sensor ensures smooth engine operation and helps avoid costly repairs by providing critical data to the engine control unit (ECU).

Crankshaft sensor vs camshaft sensor Infographic

cardiffo.com

cardiffo.com