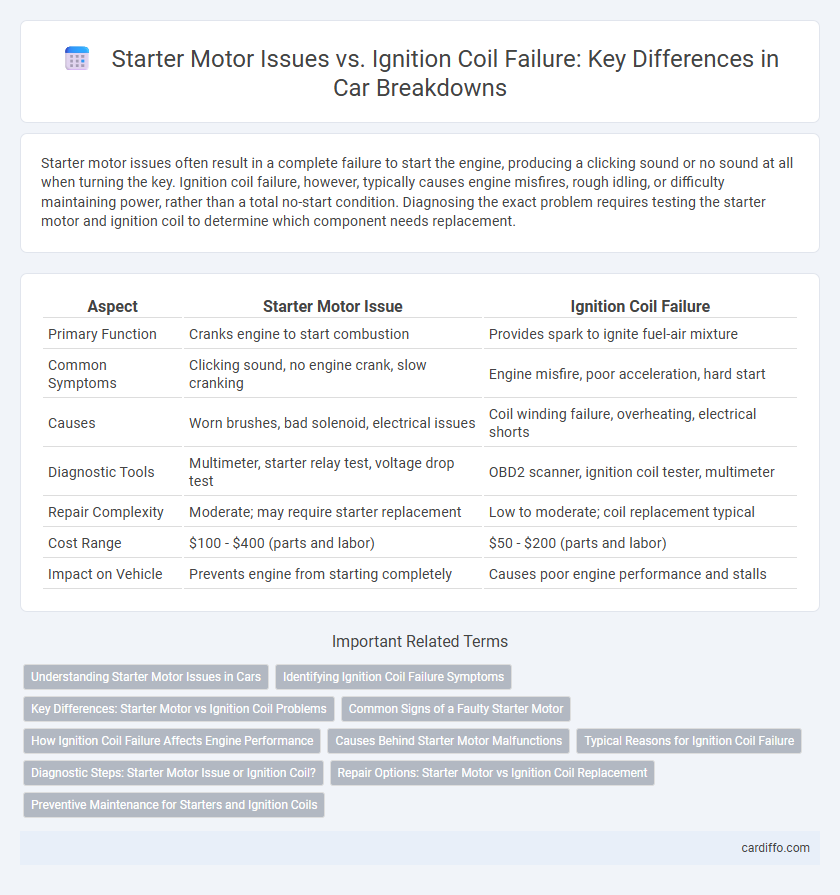

Starter motor issues often result in a complete failure to start the engine, producing a clicking sound or no sound at all when turning the key. Ignition coil failure, however, typically causes engine misfires, rough idling, or difficulty maintaining power, rather than a total no-start condition. Diagnosing the exact problem requires testing the starter motor and ignition coil to determine which component needs replacement.

Table of Comparison

| Aspect | Starter Motor Issue | Ignition Coil Failure |

|---|---|---|

| Primary Function | Cranks engine to start combustion | Provides spark to ignite fuel-air mixture |

| Common Symptoms | Clicking sound, no engine crank, slow cranking | Engine misfire, poor acceleration, hard start |

| Causes | Worn brushes, bad solenoid, electrical issues | Coil winding failure, overheating, electrical shorts |

| Diagnostic Tools | Multimeter, starter relay test, voltage drop test | OBD2 scanner, ignition coil tester, multimeter |

| Repair Complexity | Moderate; may require starter replacement | Low to moderate; coil replacement typical |

| Cost Range | $100 - $400 (parts and labor) | $50 - $200 (parts and labor) |

| Impact on Vehicle | Prevents engine from starting completely | Causes poor engine performance and stalls |

Understanding Starter Motor Issues in Cars

Starter motor issues in cars often manifest as a clicking sound or complete failure to crank the engine, distinguishing them from ignition coil failures that cause misfires and poor engine performance. Diagnosing starter motor faults involves checking the battery voltage, inspecting electrical connections, and testing the solenoid function to ensure proper power delivery. Timely repair or replacement of a faulty starter motor prevents extended downtime and avoids being stranded due to an engine that won't start.

Identifying Ignition Coil Failure Symptoms

Ignition coil failure symptoms often include engine misfires, rough idling, and difficulty starting, which differ from starter motor issues that usually present as a clicking sound or complete failure to crank. Unlike starter motor faults, ignition coil problems can trigger the check engine light and cause poor fuel economy due to incomplete combustion. Detecting these signs early helps prevent further engine damage and ensures timely replacement of the faulty ignition coil.

Key Differences: Starter Motor vs Ignition Coil Problems

Starter motor issues primarily cause engine crank failure and clicking sounds during ignition attempts, indicating mechanical or electrical faults in the motor or battery connections. Ignition coil failure leads to misfires, poor engine performance, and difficulty starting due to insufficient spark generation for combustion. While starter motor problems affect the engine's ability to turn over, ignition coil failures impact spark delivery critical for fuel ignition.

Common Signs of a Faulty Starter Motor

Common signs of a faulty starter motor include a clicking noise when turning the key, a grinding sound, or the engine failing to crank despite sufficient battery power. Unlike ignition coil failure, which often causes misfires and poor engine performance, starter motor issues prevent the engine from starting altogether. Inspecting the starter motor connections and voltage can help diagnose this problem accurately.

How Ignition Coil Failure Affects Engine Performance

Ignition coil failure causes weak or inconsistent spark generation, leading to misfires, rough idling, and reduced power output in the engine. Unlike starter motor issues that prevent engine cranking, ignition coil problems directly impact combustion efficiency and fuel economy. Diagnosing ignition coil faults involves checking spark plug misfiring patterns and engine codes for cylinder-specific errors.

Causes Behind Starter Motor Malfunctions

Starter motor malfunctions commonly arise from worn-out brushes, a faulty solenoid, or electrical connection problems such as corroded terminals or loose wiring. Insufficient battery voltage and a defective ignition switch can also impede the starter motor's ability to engage properly. Unlike ignition coil failures that disrupt spark production, starter motor issues primarily hinder the mechanical cranking of the engine.

Typical Reasons for Ignition Coil Failure

Ignition coil failure commonly occurs due to overheating caused by prolonged engine operation or a faulty cooling system, leading to insulation breakdown. Exposure to moisture and oil contamination can also degrade the coil's electrical components, resulting in intermittent sparks or complete ignition loss. Furthermore, prolonged exposure to voltage fluctuations or a weak battery can cause excessive current through the ignition coil, accelerating its wear and eventual failure.

Diagnostic Steps: Starter Motor Issue or Ignition Coil?

To diagnose a starter motor issue, first check for a clicking sound when turning the key and test battery voltage to ensure adequate power; inspect starter relay and connections for corrosion. For ignition coil failure, assess engine misfires, rough idling, and use an OBD-II scanner to detect coil-related error codes, while also measuring coil resistance with a multimeter. Differentiating these issues involves isolating electrical faults in the starter circuit versus ignition timing problems linked to coil functionality.

Repair Options: Starter Motor vs Ignition Coil Replacement

Repair options for a starter motor issue typically involve either refurbishing or completely replacing the starter motor to restore engine crank functionality. Ignition coil failure repair usually requires coil replacement to ensure proper spark generation and optimal combustion. Selecting between starter motor repair and ignition coil replacement depends on diagnostic tests pinpointing the exact cause of the no-start condition or engine misfire.

Preventive Maintenance for Starters and Ignition Coils

Regular inspection and cleaning of starter motors help prevent common issues like worn brushes or faulty solenoids, extending their lifespan and ensuring reliable engine starts. Ignition coils benefit from routine testing for resistance and insulation integrity, reducing the risk of misfires and engine performance problems. Implementing scheduled preventive maintenance minimizes breakdowns, enhances vehicle reliability, and lowers repair costs associated with starter motor and ignition coil failures.

Starter motor issue vs ignition coil failure Infographic

cardiffo.com

cardiffo.com