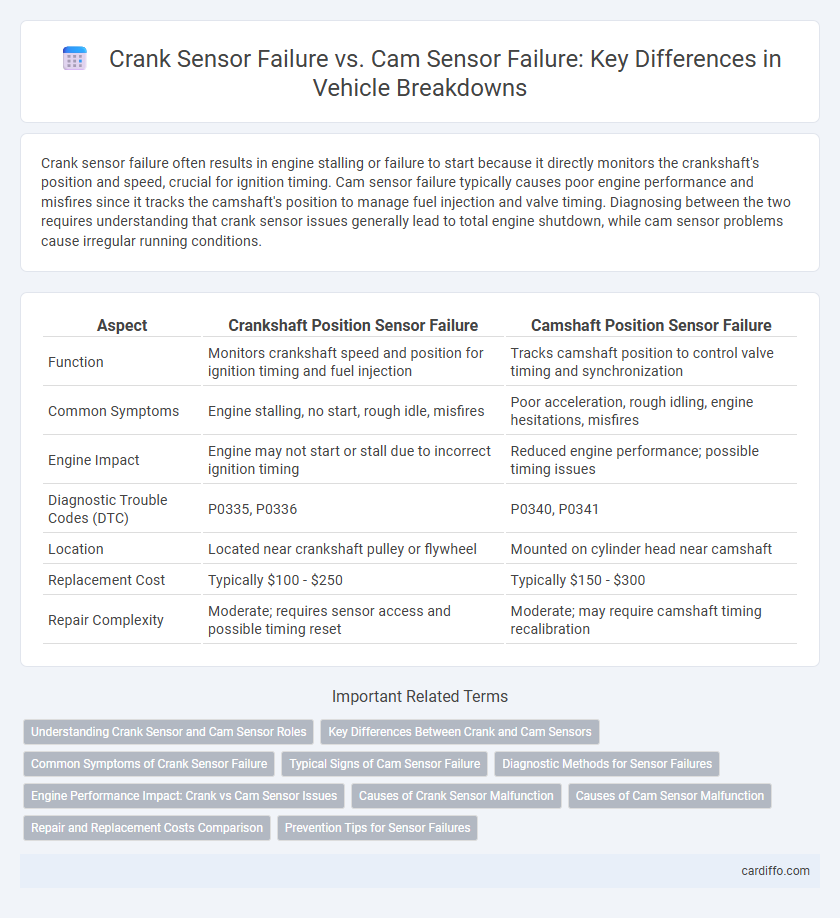

Crank sensor failure often results in engine stalling or failure to start because it directly monitors the crankshaft's position and speed, crucial for ignition timing. Cam sensor failure typically causes poor engine performance and misfires since it tracks the camshaft's position to manage fuel injection and valve timing. Diagnosing between the two requires understanding that crank sensor issues generally lead to total engine shutdown, while cam sensor problems cause irregular running conditions.

Table of Comparison

| Aspect | Crankshaft Position Sensor Failure | Camshaft Position Sensor Failure |

|---|---|---|

| Function | Monitors crankshaft speed and position for ignition timing and fuel injection | Tracks camshaft position to control valve timing and synchronization |

| Common Symptoms | Engine stalling, no start, rough idle, misfires | Poor acceleration, rough idling, engine hesitations, misfires |

| Engine Impact | Engine may not start or stall due to incorrect ignition timing | Reduced engine performance; possible timing issues |

| Diagnostic Trouble Codes (DTC) | P0335, P0336 | P0340, P0341 |

| Location | Located near crankshaft pulley or flywheel | Mounted on cylinder head near camshaft |

| Replacement Cost | Typically $100 - $250 | Typically $150 - $300 |

| Repair Complexity | Moderate; requires sensor access and possible timing reset | Moderate; may require camshaft timing recalibration |

Understanding Crank Sensor and Cam Sensor Roles

Crank sensors monitor the engine's crankshaft position and rotational speed, providing critical data for ignition timing and fuel injection to ensure efficient engine operation. Cam sensors detect the camshaft's position, synchronizing valve timing with the crankshaft for precise combustion control. Failure in either sensor disrupts engine timing, causing misfires, poor performance, or a no-start condition, but crank sensor failure more directly impacts engine crank and sensor data sequencing.

Key Differences Between Crank and Cam Sensors

Crank sensor failure primarily causes engine stalling or no start conditions due to its role in monitoring crankshaft position and speed, directly affecting ignition timing. Cam sensor failure often results in poor engine performance and misfires since it controls fuel injection timing by tracking the camshaft's position. Understanding these differences is crucial for accurate diagnosis and repair, as the crank sensor influences engine timing at startup, while the cam sensor manages timing during operation.

Common Symptoms of Crank Sensor Failure

Common symptoms of crank sensor failure include engine stalling, difficulty starting, and irregular idling. The crankshaft position sensor provides critical data for ignition timing and fuel injection, so its malfunction often triggers the check engine light and causes misfires. Unlike cam sensor issues, crank sensor failure typically results in a no-start condition or sudden engine shutdown.

Typical Signs of Cam Sensor Failure

Typical signs of cam sensor failure include engine misfires, rough idling, and difficulty starting the vehicle. Drivers may also notice a decrease in fuel efficiency and the illumination of the check engine light, often with error codes P0340 or P0341. Unlike crank sensor failure, cam sensor issues specifically affect timing and spark control, leading to uneven engine performance.

Diagnostic Methods for Sensor Failures

Diagnostic methods for crank sensor failure typically involve checking the sensor signal with an oscilloscope to detect irregular or absent pulses that affect engine timing and fuel injection. Cam sensor failure diagnostics focus on scanning the engine control unit (ECU) for trouble codes like P0340, and measuring sensor voltage output during engine cranking to identify inconsistent or no signal from the camshaft position. Both sensor failures can be further analyzed by inspecting wiring harnesses and connectors for damage or corrosion that could disrupt sensor communication with the ECU.

Engine Performance Impact: Crank vs Cam Sensor Issues

Crank sensor failure causes engine misfires, stalling, and difficulty starting by disrupting the engine's ignition timing and fuel injection synchronization. Cam sensor failure primarily affects valve timing, resulting in rough idling, reduced fuel efficiency, and increased emissions but usually allows the engine to run. Accurate sensor performance is critical for optimal engine operation, as the crank sensor directly influences crankshaft position data while the cam sensor provides camshaft position, both essential for precise engine timing.

Causes of Crank Sensor Malfunction

Crank sensor malfunction often results from wiring damage, electrical interference, or physical wear caused by heat and vibration within the engine compartment. Contaminants such as oil or metal debris can obstruct the sensor's magnetic field, leading to inaccurate signals. Faulty connectors or corrosion at the sensor terminals frequently contribute to intermittent crankshaft position data, causing engine performance issues.

Causes of Cam Sensor Malfunction

Cam sensor malfunction often results from factors such as wiring issues, sensor contamination, and mechanical wear. Exposure to dirt, oil, and engine debris can obstruct the sensor's ability to detect camshaft position accurately. Electrical faults like damaged connectors or short circuits frequently contribute to intermittent or complete sensor failure.

Repair and Replacement Costs Comparison

Crank sensor failure repair typically costs between $150 and $300, including parts and labor, while cam sensor replacement ranges from $200 to $400 due to more complex labor requirements. Crank sensors are usually easier to access, resulting in lower labor expenses compared to cam sensors that often require removal of engine components. Both sensor failures lead to engine performance issues, but replacement cost differences primarily stem from sensor location and installation complexity.

Prevention Tips for Sensor Failures

Regular maintenance and timely replacement of crankshaft and camshaft sensors are crucial to prevent sensor failures that can cause engine breakdowns. Keeping connectors clean and free of corrosion, along with routine inspections for wiring damage, enhances sensor reliability and engine performance. Using high-quality replacement parts and ensuring correct sensor installation helps avoid premature sensor issues and costly repairs.

Crank sensor failure vs cam sensor failure Infographic

cardiffo.com

cardiffo.com