A vacuum leak occurs when unmetered air enters the engine's intake manifold, causing a lean air-fuel mixture and resulting in rough idling or stalling. An exhaust leak allows burnt gases to escape before reaching the muffler, leading to increased noise, decreased fuel efficiency, and potential emission failures. Differentiating between the two is crucial for accurate diagnosis, as vacuum leaks affect engine performance while exhaust leaks impact emission control and sound levels.

Table of Comparison

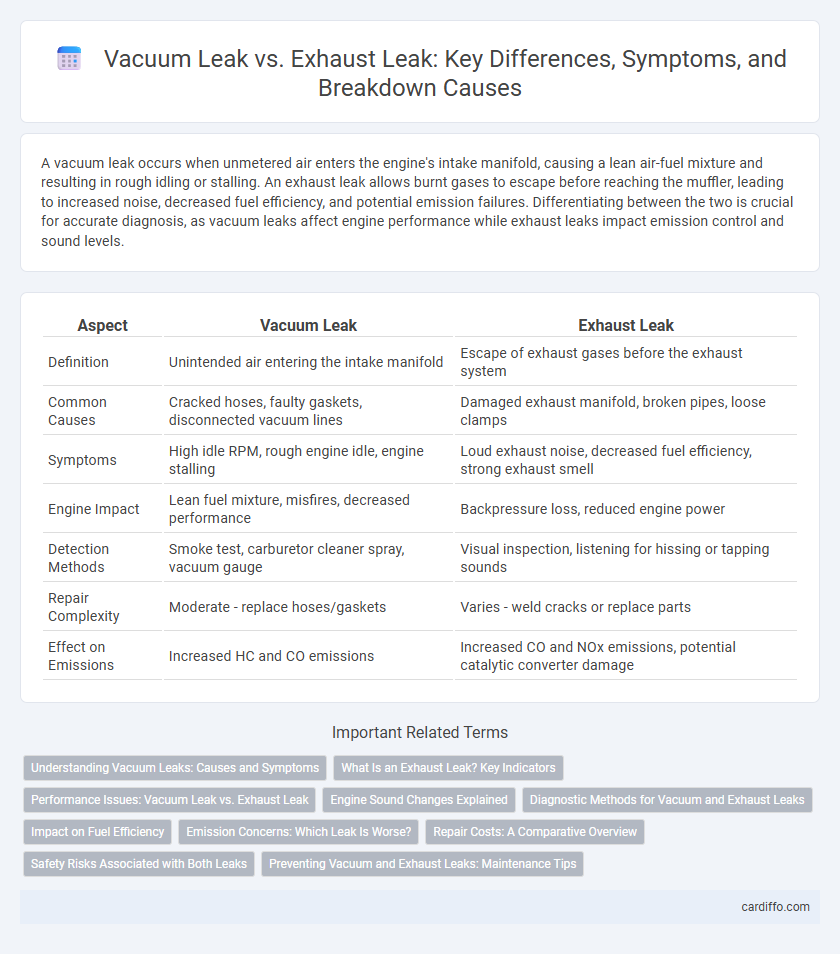

| Aspect | Vacuum Leak | Exhaust Leak |

|---|---|---|

| Definition | Unintended air entering the intake manifold | Escape of exhaust gases before the exhaust system |

| Common Causes | Cracked hoses, faulty gaskets, disconnected vacuum lines | Damaged exhaust manifold, broken pipes, loose clamps |

| Symptoms | High idle RPM, rough engine idle, engine stalling | Loud exhaust noise, decreased fuel efficiency, strong exhaust smell |

| Engine Impact | Lean fuel mixture, misfires, decreased performance | Backpressure loss, reduced engine power |

| Detection Methods | Smoke test, carburetor cleaner spray, vacuum gauge | Visual inspection, listening for hissing or tapping sounds |

| Repair Complexity | Moderate - replace hoses/gaskets | Varies - weld cracks or replace parts |

| Effect on Emissions | Increased HC and CO emissions | Increased CO and NOx emissions, potential catalytic converter damage |

Understanding Vacuum Leaks: Causes and Symptoms

Vacuum leaks occur when unmetered air enters the engine's intake manifold, disrupting the air-fuel mixture and causing rough idling, stalling, and poor acceleration. Common causes include cracked or disconnected vacuum hoses, faulty gaskets, and damaged intake manifold components. Diagnosing vacuum leaks involves inspecting hoses for damage, using a smoke machine, and monitoring engine performance for signs such as high or fluctuating idle speed.

What Is an Exhaust Leak? Key Indicators

An exhaust leak occurs when gases escape from the exhaust system before reaching the tailpipe, often due to damaged gaskets, cracked pipes, or loose connections. Key indicators of an exhaust leak include a loud hissing or tapping noise, decreased fuel efficiency, and a strong smell of exhaust fumes inside the vehicle. Early detection is crucial to prevent harmful emissions and potential engine performance issues.

Performance Issues: Vacuum Leak vs. Exhaust Leak

A vacuum leak disrupts the air-fuel mixture by allowing unmetered air into the engine, causing rough idling, hesitation, and reduced fuel efficiency. In contrast, an exhaust leak leads to decreased backpressure, resulting in loss of engine power, poor acceleration, and increased emissions. Both leaks degrade overall vehicle performance but affect engine operation through different mechanisms within the intake and exhaust systems.

Engine Sound Changes Explained

A vacuum leak causes a higher-pitched, hissing sound due to unmetered air entering the intake manifold, leading to rough idling and decreased engine performance. An exhaust leak produces a louder, rumbling or tapping noise near the exhaust manifold or muffler, often accompanied by reduced fuel efficiency and potential emission failures. Identifying the distinct engine sound changes helps diagnose the source quickly, ensuring proper repair and preventing further damage.

Diagnostic Methods for Vacuum and Exhaust Leaks

Diagnostic methods for vacuum leaks involve using a smoke machine to introduce smoke into the intake manifold, allowing visible detection of escaping air. Exhaust leaks are typically diagnosed by listening for unusual sounds near the exhaust manifold or pipes, and using exhaust gas analyzers to measure abnormal emissions. Pressure testing can also differentiate leaks by identifying drops in vacuum or exhaust system pressure.

Impact on Fuel Efficiency

A vacuum leak causes unmetered air to enter the engine, leading to a lean air-fuel mixture that decreases combustion efficiency and increases fuel consumption. An exhaust leak can disrupt oxygen sensor readings, resulting in improper fuel injection adjustments and reduced fuel economy. Both types of leaks negatively impact engine performance but differ in how they affect the fuel management system.

Emission Concerns: Which Leak Is Worse?

A vacuum leak disrupts the air-fuel mixture, causing incomplete combustion and higher hydrocarbon emissions, which can trigger the check engine light and fail emissions tests. An exhaust leak, on the other hand, allows unburned gases to escape prematurely, increasing harmful pollutants like carbon monoxide and nitrogen oxides released into the atmosphere. From an emission control perspective, exhaust leaks generally pose a greater environmental hazard due to the direct release of toxic exhaust gases before proper treatment by catalytic converters.

Repair Costs: A Comparative Overview

Repair costs for vacuum leaks typically range from $100 to $250, depending on the severity and location of the leak, while exhaust leak repairs can cost between $150 and $350 or more due to the complexity of exhaust system components. Vacuum leaks often require gasket replacements or hose repairs, which are less labor-intensive compared to exhaust leaks that might involve muffler, manifold, or pipe replacements. Understanding these cost differences helps prioritize repairs based on budget constraints and vehicle performance needs.

Safety Risks Associated with Both Leaks

Vacuum leaks can lead to engine misfires and increased emissions, posing health risks due to the potential release of harmful gases into the cabin. Exhaust leaks risk exposure to toxic carbon monoxide, which can cause dizziness, headaches, or even fatal poisoning if inhaled in confined spaces. Both leaks compromise vehicle safety by reducing engine performance and increasing the likelihood of mechanical failure during operation.

Preventing Vacuum and Exhaust Leaks: Maintenance Tips

Preventing vacuum and exhaust leaks requires regular inspection of hoses, gaskets, and seals to identify cracks or wear before failure occurs. Use quality replacement parts and ensure proper torque specifications during installation to maintain airtight connections. Routine engine tune-ups and monitoring for unusual noises or changes in performance can detect leaks early, minimizing damage and maintaining fuel efficiency.

Vacuum leak vs exhaust leak Infographic

cardiffo.com

cardiffo.com