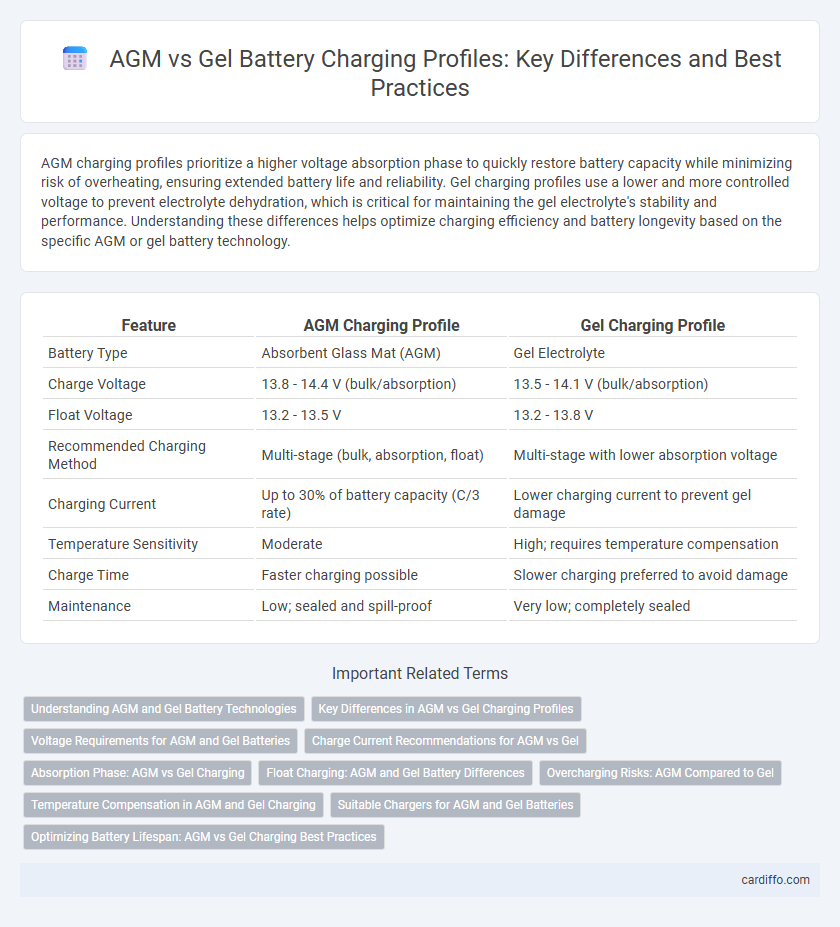

AGM charging profiles prioritize a higher voltage absorption phase to quickly restore battery capacity while minimizing risk of overheating, ensuring extended battery life and reliability. Gel charging profiles use a lower and more controlled voltage to prevent electrolyte dehydration, which is critical for maintaining the gel electrolyte's stability and performance. Understanding these differences helps optimize charging efficiency and battery longevity based on the specific AGM or gel battery technology.

Table of Comparison

| Feature | AGM Charging Profile | Gel Charging Profile |

|---|---|---|

| Battery Type | Absorbent Glass Mat (AGM) | Gel Electrolyte |

| Charge Voltage | 13.8 - 14.4 V (bulk/absorption) | 13.5 - 14.1 V (bulk/absorption) |

| Float Voltage | 13.2 - 13.5 V | 13.2 - 13.8 V |

| Recommended Charging Method | Multi-stage (bulk, absorption, float) | Multi-stage with lower absorption voltage |

| Charging Current | Up to 30% of battery capacity (C/3 rate) | Lower charging current to prevent gel damage |

| Temperature Sensitivity | Moderate | High; requires temperature compensation |

| Charge Time | Faster charging possible | Slower charging preferred to avoid damage |

| Maintenance | Low; sealed and spill-proof | Very low; completely sealed |

Understanding AGM and Gel Battery Technologies

AGM (Absorbent Glass Mat) batteries feature a charging profile that prioritizes a higher charging voltage and faster recharge times due to their low internal resistance and enhanced electrolyte absorption. Gel batteries use a charging profile with lower voltage and slower charging rates to prevent damage to the silica-based gel electrolyte, ensuring longer battery life and stability. Understanding the distinct charging requirements of AGM and Gel technologies optimizes performance and longevity across various applications such as solar energy systems and deep cycle usage.

Key Differences in AGM vs Gel Charging Profiles

AGM batteries require a higher charging voltage, typically around 14.4-14.6V, to ensure full charge and prevent sulfation, while gel batteries need a lower, more controlled voltage of approximately 14.1-14.3V to avoid gas buildup and electrolyte drying. Gel charging profiles feature longer absorption times with reduced current to protect the gel electrolyte, contrasting with AGM profiles that allow faster charge rates due to better internal gas recombination. Temperature compensation differs as well, with AGM batteries tolerating wider temperature ranges, whereas gel batteries demand more precise voltage adjustments to maintain longevity and performance.

Voltage Requirements for AGM and Gel Batteries

AGM batteries require a charging voltage typically between 14.4V to 14.7V during the bulk phase to ensure proper absorption and avoid overcharging, while gel batteries demand a slightly lower voltage range around 14.1V to 14.4V to prevent gel electrolyte damage. Maintaining these specific voltage limits optimizes battery life and performance by preventing excessive gassing in AGM types and avoiding dehydration in gel batteries. Proper charger settings aligned with these profiles are essential for preserving capacity and extending the service life of both AGM and gel batteries.

Charge Current Recommendations for AGM vs Gel

AGM batteries typically require a higher charge current, around 10-30% of their capacity, to achieve optimal charging without overheating. Gel batteries demand a lower and more controlled charge current, often limited to 10-15% of their capacity, to prevent electrolyte damage and ensure longevity. Following manufacturer-specific charge current recommendations is essential to maintain battery health and performance for both AGM and Gel types.

Absorption Phase: AGM vs Gel Charging

The absorption phase for AGM batteries typically involves a higher voltage of around 14.4-14.6 volts, ensuring rapid and efficient charging while preventing overcharging and thermal runaway. Gel batteries require a lower absorption voltage, usually between 14.1-14.3 volts, to protect the delicate silica-based electrolyte and avoid permanent damage from excessive gassing. Maintaining the correct absorption voltage is critical for optimizing battery lifespan and performance in both AGM and Gel battery types.

Float Charging: AGM and Gel Battery Differences

AGM batteries require a float voltage typically between 13.5 to 13.8 volts to maintain full charge without overcharging, while gel batteries need a lower float voltage around 13.2 to 13.4 volts to prevent electrolyte drying and damage. The distinct float charging requirements arise from the different electrolyte immobilization methods, where AGM uses absorbed glass mat separators and gel batteries use a silica-based gel. Proper float charging ensures extended battery life and optimal performance by avoiding overvoltage stress unique to each battery technology.

Overcharging Risks: AGM Compared to Gel

AGM batteries exhibit higher sensitivity to overcharging due to their sealed design and thin-plate construction, which can cause electrolyte loss and reduced lifespan if charged improperly. Gel batteries have a lower risk of overcharging damage because their silica-based electrolyte gel resists stratification and gas escape, maintaining stability under varied charging conditions. Proper charger settings tailored to the specific charging profile of AGM or Gel batteries are crucial to mitigate overcharging risks and optimize battery performance.

Temperature Compensation in AGM and Gel Charging

AGM batteries require temperature-compensated charging profiles to prevent overcharging and extend battery life, adjusting voltage based on ambient temperature changes typically around -5 mV/degC per cell. Gel batteries also need temperature compensation, but their charging voltage is generally lower and more sensitive to temperature fluctuations, often regulated near -4 mV/degC per cell to avoid electrolyte damage. Proper temperature compensation in both AGM and Gel charging profiles ensures optimal performance, enhances battery longevity, and reduces the risk of thermal runaway or capacity loss.

Suitable Chargers for AGM and Gel Batteries

Suitable chargers for AGM batteries feature controlled voltage and current settings with multi-stage charging profiles tailored to prevent overcharging and sulfation, typically including bulk, absorption, and float stages. Gel batteries require chargers with lower voltage limits and temperature compensation to accommodate their sensitivity to overcharging and thermal stress, ensuring the gel electrolyte remains stable. Chargers optimized for AGM and Gel batteries often include selectable modes or smart technology that automatically adjusts voltage and current parameters to extend battery life and maintain peak performance.

Optimizing Battery Lifespan: AGM vs Gel Charging Best Practices

Optimizing battery lifespan requires understanding the distinct charging profiles for AGM and Gel batteries, as each demands specific voltage settings to prevent overcharging or undercharging. AGM batteries benefit from higher charging voltages typically around 14.4-14.6 volts during bulk charging, while Gel batteries require more controlled, lower voltages near 14.1-14.3 volts to avoid damaging silica gel electrolytes. Properly tailored charging algorithms extend cycle life and maintain capacity by minimizing thermal stress and sulfation risks unique to each battery technology.

AGM Charging Profile vs Gel Charging Profile Infographic

cardiffo.com

cardiffo.com