VRLA batteries offer sealed, maintenance-free operation with improved safety compared to conventional flooded batteries, which require regular water refilling and ventilation. VRLA technology provides better resistance to leakage and can be installed in various orientations, making them ideal for confined spaces. Conventional batteries often have lower initial costs but demand more upkeep and careful handling due to their open design.

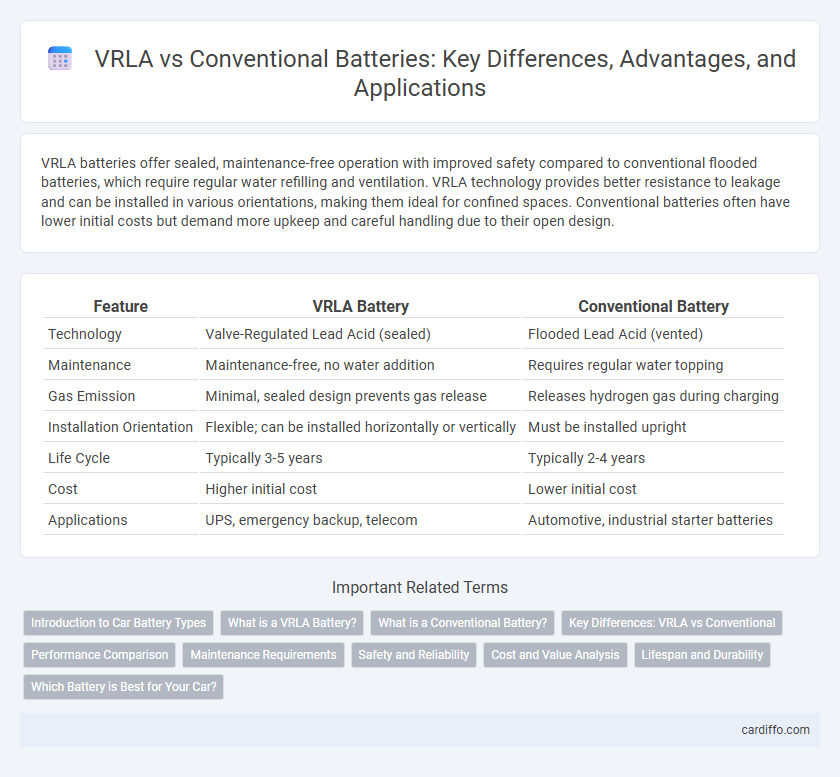

Table of Comparison

| Feature | VRLA Battery | Conventional Battery |

|---|---|---|

| Technology | Valve-Regulated Lead Acid (sealed) | Flooded Lead Acid (vented) |

| Maintenance | Maintenance-free, no water addition | Requires regular water topping |

| Gas Emission | Minimal, sealed design prevents gas release | Releases hydrogen gas during charging |

| Installation Orientation | Flexible; can be installed horizontally or vertically | Must be installed upright |

| Life Cycle | Typically 3-5 years | Typically 2-4 years |

| Cost | Higher initial cost | Lower initial cost |

| Applications | UPS, emergency backup, telecom | Automotive, industrial starter batteries |

Introduction to Car Battery Types

Valve-Regulated Lead-Acid (VRLA) batteries offer maintenance-free operation and enhanced safety through a sealed design, making them ideal for modern vehicles with complex electrical systems. Conventional flooded lead-acid batteries require regular maintenance such as water refilling and produce gas during operation, posing ventilation challenges. VRLA batteries deliver improved lifespan and vibration resistance, catering to the growing demand for reliable, low-maintenance car battery solutions.

What is a VRLA Battery?

A VRLA (Valve-Regulated Lead-Acid) battery is a sealed lead-acid battery designed with a safety valve to regulate internal gas pressure, preventing leakage and minimizing maintenance. It uses absorbed glass mat (AGM) or gel electrolyte technology, which immobilizes the electrolyte for enhanced durability and safer operation compared to conventional flooded lead-acid batteries. VRLA batteries are widely used in backup power systems, telecommunications, and uninterruptible power supplies (UPS) due to their reliability and low maintenance requirements.

What is a Conventional Battery?

A conventional battery, often referred to as a flooded lead-acid battery, uses a liquid electrolyte that freely moves between the lead plates, requiring regular maintenance such as electrolyte level checks and refilling with distilled water. This type of battery offers high surge currents and is commonly used in automotive and deep-cycle applications but poses risks of acid spills and gas emissions during charging. Compared to VRLA (Valve-Regulated Lead-Acid) batteries, conventional batteries are less sealed and have a shorter lifespan under deep discharge conditions.

Key Differences: VRLA vs Conventional

VRLA (Valve-Regulated Lead-Acid) batteries feature sealed construction with a pressure release valve, enabling maintenance-free operation and preventing electrolyte leakage, unlike conventional flooded lead-acid batteries that require regular water refilling and ventilation. VRLA batteries offer better resistance to vibration, lower gas emissions, and improved safety, while conventional batteries generally provide higher tolerance to overcharging and longer service life in certain heavy-duty applications. Key differences include VRLA's sealed design for convenience and safety versus conventional batteries' open-cell design that demands consistent maintenance and monitoring.

Performance Comparison

VRLA (Valve-Regulated Lead-Acid) batteries offer superior performance compared to conventional flooded lead-acid batteries due to their sealed design, which prevents electrolyte spillage and reduces maintenance requirements. VRLA batteries exhibit better charge retention, longer cycle life, and enhanced resistance to vibration and shock, making them ideal for critical applications. In terms of efficiency, VRLA batteries provide higher energy density and faster recharge rates, resulting in improved overall reliability for backup power systems.

Maintenance Requirements

VRLA batteries require minimal maintenance due to their sealed design, eliminating the need for regular electrolyte checks or water refilling. Conventional flooded lead-acid batteries demand frequent inspection and maintenance, including electrolyte level monitoring and periodic water addition to prevent sulfation and ensure optimal performance. The reduced maintenance of VRLA batteries makes them suitable for applications where accessibility and upkeep are challenging.

Safety and Reliability

VRLA (Valve-Regulated Lead-Acid) batteries offer enhanced safety due to their sealed design, which minimizes acid spills and reduces the risk of gas leakage compared to conventional flooded lead-acid batteries. Their maintenance-free operation and built-in pressure relief valves ensure consistent reliability by preventing overpressure build-up and electrolyte loss. Conventional batteries, while robust, require regular maintenance and are more prone to acid leakage and corrosion, impacting long-term safety and reliability.

Cost and Value Analysis

VRLA batteries typically offer a higher upfront cost compared to conventional flooded lead-acid batteries but provide lower maintenance expenses and longer service life, enhancing overall value in applications requiring reliable, sealed power sources. Conventional batteries have lower initial costs but incur higher maintenance, including electrolyte watering and ventilation, increasing long-term operational expenses. Evaluating total cost of ownership, VRLA batteries often deliver superior value through reduced downtime and safety benefits, making them ideal for critical backup systems despite higher initial investment.

Lifespan and Durability

VRLA (Valve-Regulated Lead-Acid) batteries offer enhanced lifespan and durability compared to conventional flooded lead-acid batteries due to their sealed design that prevents electrolyte loss and reduces maintenance. The maintenance-free operation of VRLA batteries reduces corrosion and extends cycle life, making them suitable for applications requiring long-term reliability. Conventional batteries, while typically less expensive initially, generally have shorter lifespans and require regular maintenance to sustain performance and prevent premature failure.

Which Battery is Best for Your Car?

VRLA (Valve-Regulated Lead-Acid) batteries offer maintenance-free operation, spill-proof design, and better resistance to vibration compared to conventional flooded lead-acid batteries. Conventional batteries typically cost less and perform well in standard conditions but require periodic water refilling and can leak acid if tipped. For modern vehicles with start-stop systems or limited engine bays, VRLA batteries provide superior durability and safety, making them the best choice for high-performance and maintenance-conscious car owners.

VRLA vs Conventional Infographic

cardiffo.com

cardiffo.com