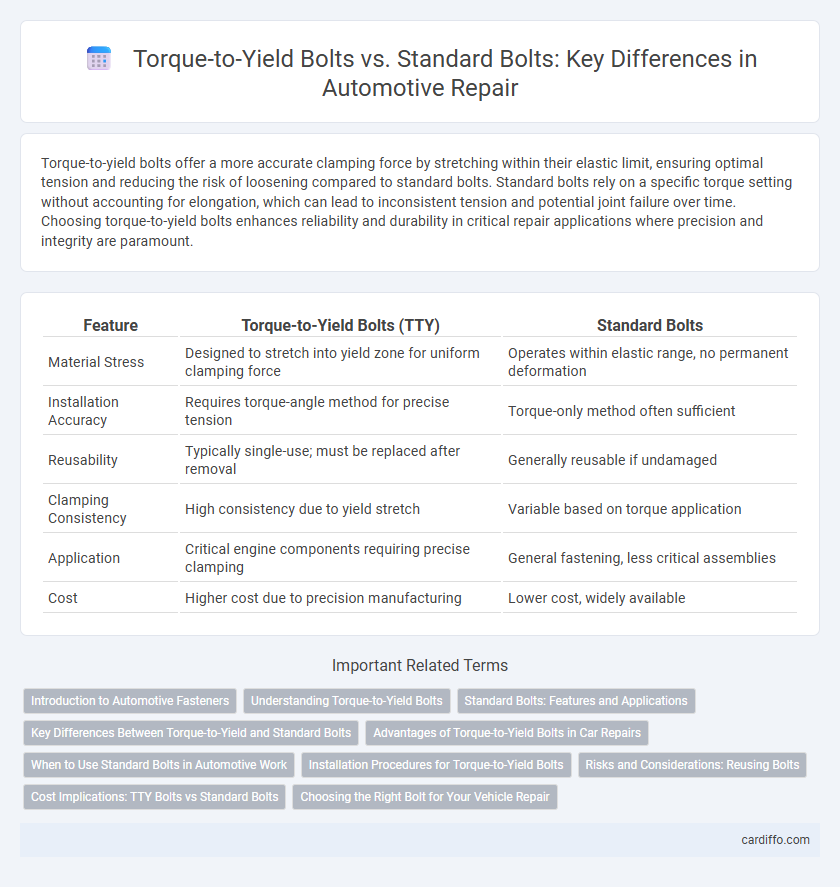

Torque-to-yield bolts offer a more accurate clamping force by stretching within their elastic limit, ensuring optimal tension and reducing the risk of loosening compared to standard bolts. Standard bolts rely on a specific torque setting without accounting for elongation, which can lead to inconsistent tension and potential joint failure over time. Choosing torque-to-yield bolts enhances reliability and durability in critical repair applications where precision and integrity are paramount.

Table of Comparison

| Feature | Torque-to-Yield Bolts (TTY) | Standard Bolts |

|---|---|---|

| Material Stress | Designed to stretch into yield zone for uniform clamping force | Operates within elastic range, no permanent deformation |

| Installation Accuracy | Requires torque-angle method for precise tension | Torque-only method often sufficient |

| Reusability | Typically single-use; must be replaced after removal | Generally reusable if undamaged |

| Clamping Consistency | High consistency due to yield stretch | Variable based on torque application |

| Application | Critical engine components requiring precise clamping | General fastening, less critical assemblies |

| Cost | Higher cost due to precision manufacturing | Lower cost, widely available |

Introduction to Automotive Fasteners

Torque-to-yield bolts are designed to stretch within their elastic limit, providing consistent clamping force and improved joint reliability compared to standard bolts. These bolts are commonly used in critical engine components, such as cylinder head assemblies, where precise torque application and load distribution are essential. Standard bolts, while suitable for less demanding applications, may not maintain optimal tension under repeated stress, increasing the risk of loosening or failure in high-performance automotive repairs.

Understanding Torque-to-Yield Bolts

Torque-to-yield bolts are designed to stretch within their elastic limit during installation, providing a precise clamping force that enhances joint integrity and prevents loosening under dynamic loads. Unlike standard bolts, which rely on torque values that may cause inconsistent clamping, torque-to-yield bolts ensure uniform tension and improved sealing, critical in high-performance engine repairs and assemblies. Their one-time-use design requires replacement after removal to maintain optimal performance and avoid potential hardware failure.

Standard Bolts: Features and Applications

Standard bolts feature uniform thread pitch and are made from various grades of steel, providing reliable clamping force for general repair and assembly tasks. Their ability to be reused makes them cost-effective for applications such as machinery maintenance, automotive repairs, and construction fastenings. These bolts are ideal for situations where precise torque control is less critical than the ease of installation and removal.

Key Differences Between Torque-to-Yield and Standard Bolts

Torque-to-yield (TTY) bolts are engineered to stretch beyond their elastic limit, providing a more precise clamping force compared to standard bolts, which rely on elastic deformation within a specific torque range. TTY bolts are typically used in critical applications like cylinder heads, requiring replacement after each use due to permanent elongation, while standard bolts can often be reused if not deformed. The key difference lies in their installation method and lifespan: TTY bolts use torque-then-angle tightening to ensure consistent preload, whereas standard bolts depend solely on torque values and maintain elasticity without permanent deformation.

Advantages of Torque-to-Yield Bolts in Car Repairs

Torque-to-yield bolts offer superior clamping force and consistent preload, which enhances engine sealing and reduces the risk of bolt loosening in critical automotive repairs. Their stretch-to-yield design ensures precise torque application, preventing over-tightening and minimizing the need for retightening during maintenance. These bolts improve reliability and longevity in high-stress engine components compared to standard bolts, making them essential for modern car repair applications.

When to Use Standard Bolts in Automotive Work

Standard bolts should be used in automotive work when components require repeated assembly and disassembly or when torque-to-yield bolts are not specified by the manufacturer. These bolts maintain structural integrity for parts like engine accessories, brackets, and suspension components that do not experience extreme stress or stretching. Using standard bolts in these applications ensures reliable performance and simplifies maintenance without risking bolt deformation or loss of clamping force.

Installation Procedures for Torque-to-Yield Bolts

Torque-to-yield (TTY) bolts require specific installation procedures involving a precise initial torque followed by an angle-tightening method to stretch the bolt within its elastic limit, ensuring a secure and consistent clamp load. Unlike standard bolts tightened to a specified torque alone, TTY bolts demand careful use of torque angle gauges or digital angle tools to achieve the correct yield stretch and avoid over-tightening or bolt failure. Proper lubrication and adherence to manufacturer specifications during TTY bolt installation are critical to maintaining engine integrity and repair reliability.

Risks and Considerations: Reusing Bolts

Reusing torque-to-yield bolts significantly increases the risk of bolt failure due to their plastic deformation during initial installation, compromising clamping force and structural integrity. Standard bolts generally tolerate multiple uses but require careful inspection for wear or damage to prevent loosening or breakage. Failure to replace torque-to-yield bolts as recommended can lead to catastrophic engine or component damage, making adherence to manufacturer guidelines critical in repair scenarios.

Cost Implications: TTY Bolts vs Standard Bolts

Torque-to-yield (TTY) bolts generally incur higher initial costs compared to standard bolts due to their specialized design and the need for precise installation procedures. However, TTY bolts provide improved sealing and uniform clamping force, reducing the risk of engine leaks and potential repair expenses over time. Standard bolts offer lower upfront costs but may lead to increased maintenance and replacement costs, impacting the overall cost-effectiveness in long-term engine repairs.

Choosing the Right Bolt for Your Vehicle Repair

Torque-to-yield bolts provide a precise clamping force by stretching within their elastic limit, ensuring consistent torque and enhanced joint integrity during critical engine repairs. Standard bolts offer reusability and ease of installation but may not deliver the same level of stress distribution, potentially affecting long-term durability. Selecting the correct bolt depends on the repair's specific requirements, manufacturer specifications, and whether the application demands high precision and strength maintenance under thermal conditions.

Torque-to-Yield Bolts vs Standard Bolts Infographic

cardiffo.com

cardiffo.com