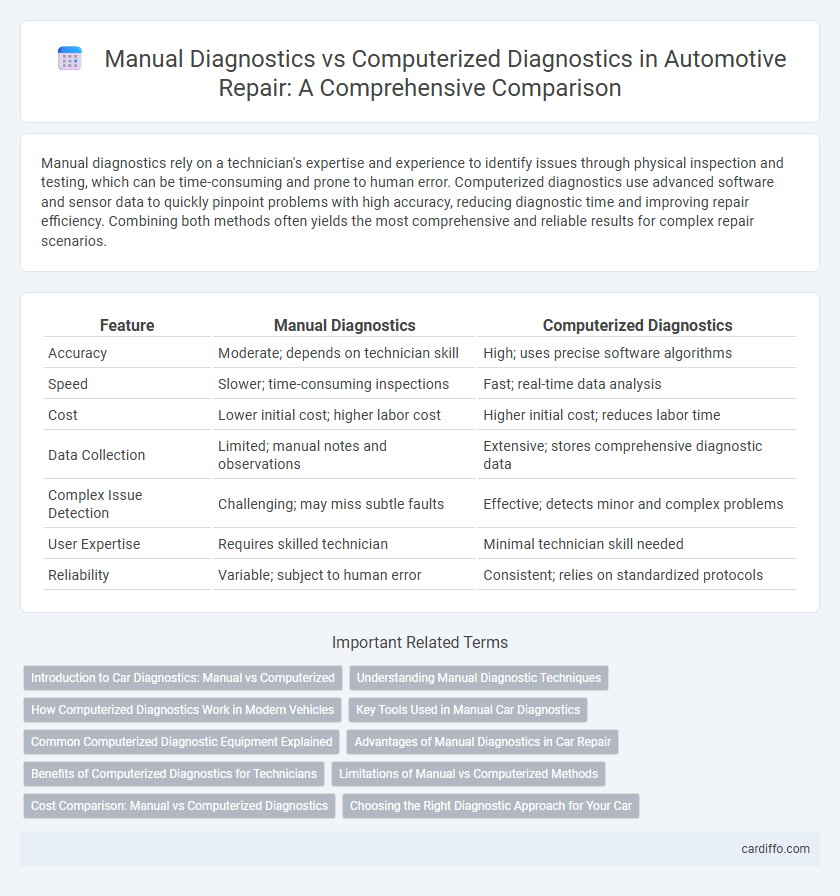

Manual diagnostics rely on a technician's expertise and experience to identify issues through physical inspection and testing, which can be time-consuming and prone to human error. Computerized diagnostics use advanced software and sensor data to quickly pinpoint problems with high accuracy, reducing diagnostic time and improving repair efficiency. Combining both methods often yields the most comprehensive and reliable results for complex repair scenarios.

Table of Comparison

| Feature | Manual Diagnostics | Computerized Diagnostics |

|---|---|---|

| Accuracy | Moderate; depends on technician skill | High; uses precise software algorithms |

| Speed | Slower; time-consuming inspections | Fast; real-time data analysis |

| Cost | Lower initial cost; higher labor cost | Higher initial cost; reduces labor time |

| Data Collection | Limited; manual notes and observations | Extensive; stores comprehensive diagnostic data |

| Complex Issue Detection | Challenging; may miss subtle faults | Effective; detects minor and complex problems |

| User Expertise | Requires skilled technician | Minimal technician skill needed |

| Reliability | Variable; subject to human error | Consistent; relies on standardized protocols |

Introduction to Car Diagnostics: Manual vs Computerized

Manual car diagnostics rely on a mechanic's expertise to visually inspect and test vehicle components, often using basic tools such as multimeters and test lights to identify issues. Computerized diagnostics utilize onboard diagnostic systems (OBD-II) and specialized software to read error codes, providing precise and real-time data on engine, transmission, and sensor performance. While manual methods offer hands-on understanding and flexibility, computerized diagnostics deliver faster, more accurate detection of complex problems through advanced data analysis.

Understanding Manual Diagnostic Techniques

Manual diagnostic techniques involve hands-on inspection and sensory evaluation to identify mechanical faults, relying heavily on the technician's experience and intuition. These methods include listening for unusual noises, checking for vibrations, and visually inspecting components for wear or damage. Mastery of manual diagnostics provides a fundamental understanding of machinery behavior, complementing computerized diagnostics by pinpointing issues that may not trigger electronic sensors.

How Computerized Diagnostics Work in Modern Vehicles

Computerized diagnostics in modern vehicles utilize onboard diagnostic (OBD) systems that continuously monitor engine performance, emission control, and other critical components through embedded sensors and electronic control units (ECUs). These systems generate real-time error codes that mechanics interpret using specialized scan tools to pinpoint issues quickly, enhancing repair accuracy and efficiency. Advanced diagnostic software integrates data from multiple vehicle systems, enabling predictive maintenance and reducing the likelihood of unexpected breakdowns.

Key Tools Used in Manual Car Diagnostics

Key tools used in manual car diagnostics include multimeters, OBD-II scanners, test lights, and compression testers. Mechanics often rely on stethoscopes to detect engine noises and vacuum gauges to assess engine performance manually. These tools enable precise identification of mechanical issues without the need for computerized systems.

Common Computerized Diagnostic Equipment Explained

Common computerized diagnostic equipment such as OBD-II scanners, code readers, and multimeters provide precise fault codes and real-time data, streamlining the repair process compared to manual diagnostics. These devices quickly identify engine, transmission, and electronic system issues by interfacing directly with the vehicle's onboard computer, reducing guesswork and repair times. Advanced scanners also offer live sensor data, freeze frame analysis, and readiness monitors, enhancing accuracy in diagnosing complex automotive problems.

Advantages of Manual Diagnostics in Car Repair

Manual diagnostics in car repair allows technicians to leverage hands-on experience and intuition, identifying subtle issues that computerized systems might overlook. It offers flexibility in troubleshooting rare or complex problems without dependence on specific software or hardware updates. This method provides a deeper understanding of vehicle mechanics, fostering precise and customized repair solutions.

Benefits of Computerized Diagnostics for Technicians

Computerized diagnostics enhance repair accuracy by quickly identifying specific system faults using advanced algorithms and real-time data analysis. This technology reduces diagnostic time, allowing technicians to pinpoint issues without extensive manual testing. Integration with vehicle software enables seamless updates and access to manufacturer databases, improving repair efficiency and reducing error rates.

Limitations of Manual vs Computerized Methods

Manual diagnostics rely heavily on technician experience and can miss complex or hidden issues, leading to less accurate problem identification. Computerized diagnostics utilize advanced sensors and diagnostic software to detect subtle faults and provide precise error codes, improving troubleshooting efficiency. However, computerized systems require up-to-date software and compatible hardware, limiting their effectiveness if not properly maintained.

Cost Comparison: Manual vs Computerized Diagnostics

Manual diagnostics typically incur higher labor costs due to the time-intensive process of physical inspections and the reliance on skilled technicians, while computerized diagnostics reduce labor expenses by quickly analyzing vehicle data through specialized software. Equipment investment for computerized diagnostics includes the initial purchase of diagnostic tools and software updates, which can be costly but amortized over multiple uses, whereas manual diagnostics require minimal initial equipment but increased ongoing labor expenditure. Overall, computerized diagnostics offer cost savings in the long term by minimizing diagnostic time and improving accuracy, leading to fewer repair errors and reduced vehicle downtime.

Choosing the Right Diagnostic Approach for Your Car

Manual diagnostics offer hands-on inspection and experienced intuition crucial for recognizing subtle vehicle issues often missed by computerized systems. Computerized diagnostics provide quick, precise data analysis through OBD-II scanners, enabling identification of error codes and system malfunctions efficiently. Selecting the right diagnostic approach depends on the car's complexity, problem nature, and technician expertise, combining both methods often yields the most accurate results.

manual diagnostics vs computerized diagnostics Infographic

cardiffo.com

cardiffo.com