Panel beating involves reshaping and repairing the existing metal panels to restore their original form after damage, preserving the vehicle's structure and reducing costs. Panel replacement entails removing the damaged section entirely and installing a new panel, often necessary when the damage is severe or the metal is too compromised to repair effectively. Choosing between panel beating and replacement depends on the extent of the damage, repair costs, and the desired quality of the vehicle's finish.

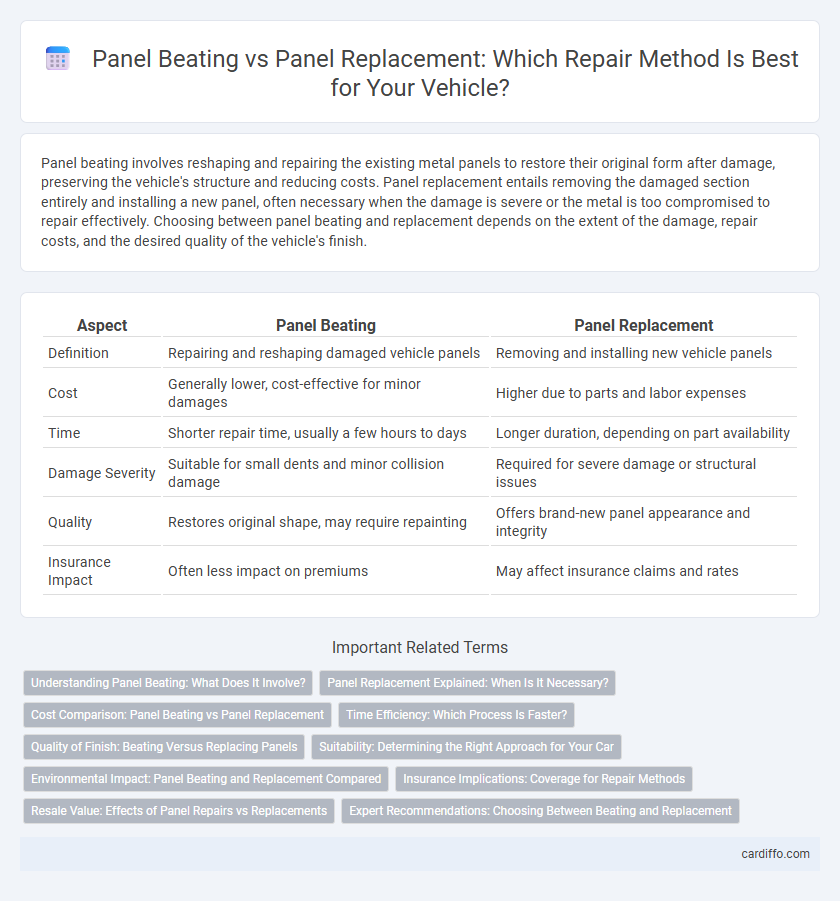

Table of Comparison

| Aspect | Panel Beating | Panel Replacement |

|---|---|---|

| Definition | Repairing and reshaping damaged vehicle panels | Removing and installing new vehicle panels |

| Cost | Generally lower, cost-effective for minor damages | Higher due to parts and labor expenses |

| Time | Shorter repair time, usually a few hours to days | Longer duration, depending on part availability |

| Damage Severity | Suitable for small dents and minor collision damage | Required for severe damage or structural issues |

| Quality | Restores original shape, may require repainting | Offers brand-new panel appearance and integrity |

| Insurance Impact | Often less impact on premiums | May affect insurance claims and rates |

Understanding Panel Beating: What Does It Involve?

Panel beating involves repairing vehicle body panels by reshaping, hammering, and filling dents or damage to restore the original contours without replacing the entire panel. Skilled technicians use specialized tools to carefully straighten metal, remove imperfections, and prepare surfaces for repainting, ensuring a seamless finish. This process is cost-effective and preserves the original parts, maintaining the vehicle's structural integrity and value.

Panel Replacement Explained: When Is It Necessary?

Panel replacement becomes necessary when the damage to a vehicle's body panel is extensive, such as deep dents, corrosion, or structural compromise, making repair impossible or unsafe. Unlike panel beating, which involves reshaping and smoothing damaged panels, replacement restores the vehicle's integrity by installing a new, factory-spec panel. This approach ensures optimal safety, appearance, and longevity, especially after major collisions or severe rust damage.

Cost Comparison: Panel Beating vs Panel Replacement

Panel beating is generally more cost-effective than panel replacement as it involves repairing the existing metal, reducing material expenses. Replacement requires purchasing a new panel and additional labor costs for fitting and painting, which significantly increases the overall price. Costs vary depending on the severity of damage, vehicle make, and part availability, but panel beating typically saves 30-50% compared to full panel replacement.

Time Efficiency: Which Process Is Faster?

Panel beating typically offers faster turnaround times compared to panel replacement since it involves reshaping and repairing the existing metal, reducing the need for part sourcing and fitting. Panel replacement requires removing the damaged section and installing a new panel, which can be time-consuming due to alignment, welding, and paint matching processes. Choosing panel beating for minor dents and damages enhances time efficiency without compromising the vehicle's structural integrity.

Quality of Finish: Beating Versus Replacing Panels

Panel beating preserves the original metal, ensuring a seamless, factory-quality finish with no mismatched textures or colors, critical for maintaining vehicle value. Replacing panels can introduce inconsistencies in paint matching and alignment, often resulting in visible seams or color variations that detract from the overall finish quality. Expert panel beating repairs dents and minor damage without compromising the vehicle's structural integrity or aesthetic appeal.

Suitability: Determining the Right Approach for Your Car

Panel beating is ideal for repairing minor dents and deformations without compromising the original metal, preserving the car's structural integrity and factory finish. Panel replacement becomes suitable when damage is extensive, involving severe rust or structural faults that cannot be restored to safety standards. Assessing the extent of the damage and cost-effectiveness helps determine whether panel beating or replacement provides the best long-term solution for your vehicle.

Environmental Impact: Panel Beating and Replacement Compared

Panel beating preserves the original vehicle parts, significantly reducing waste and the need for new materials, which lowers the environmental footprint. Panel replacement involves discarding damaged panels and manufacturing new ones, leading to higher resource consumption and increased emissions from production and transportation. Choosing panel beating over replacement supports sustainability by minimizing landfill waste and conserving raw materials in the automotive repair process.

Insurance Implications: Coverage for Repair Methods

Insurance coverage for panel beating typically includes repairs that restore the original panel's shape and integrity, often resulting in lower claim costs and quicker settlements. In contrast, panel replacement claims may lead to higher payouts due to the cost of new parts and labor, potentially affecting policy deductibles and premium adjustments. Understanding insurer policies on repair methods is crucial for policyholders to optimize claim approvals and minimize out-of-pocket expenses.

Resale Value: Effects of Panel Repairs vs Replacements

Panel beating preserves a vehicle's original structure and paint, maintaining higher resale value compared to panel replacement. Replacing a panel can lead to mismatched paint and potential misalignment, which often reduces the vehicle's market appeal. Buyers generally favor cars with original panels intact, perceiving them as less tampered and more reliable.

Expert Recommendations: Choosing Between Beating and Replacement

Expert recommendations for choosing between panel beating and panel replacement emphasize assessing the damage severity and structural integrity of the vehicle's panels. Panel beating is advised for minor dents and surface damage to restore original contours without compromising safety, while replacement is recommended for extensive corrosion, deep impact, or where panel strength is irreparably weakened. Cost-effectiveness, repair durability, and maintaining manufacturer safety standards guide technicians in selecting the optimal repair method.

Panel beating vs Panel replacement Infographic

cardiffo.com

cardiffo.com