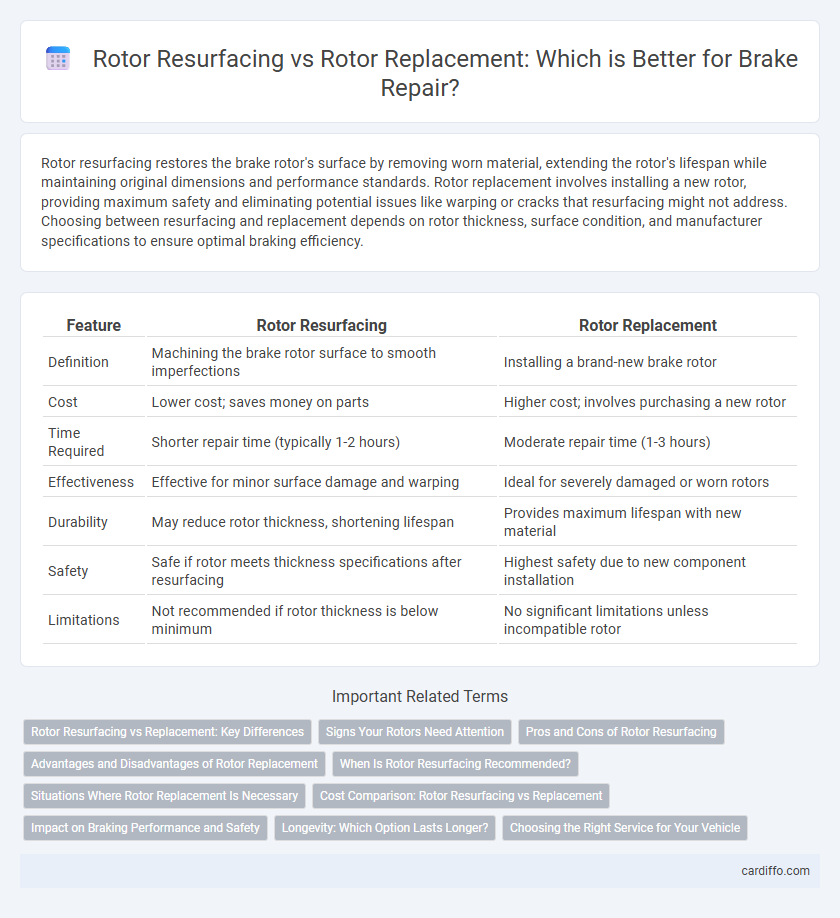

Rotor resurfacing restores the brake rotor's surface by removing worn material, extending the rotor's lifespan while maintaining original dimensions and performance standards. Rotor replacement involves installing a new rotor, providing maximum safety and eliminating potential issues like warping or cracks that resurfacing might not address. Choosing between resurfacing and replacement depends on rotor thickness, surface condition, and manufacturer specifications to ensure optimal braking efficiency.

Table of Comparison

| Feature | Rotor Resurfacing | Rotor Replacement |

|---|---|---|

| Definition | Machining the brake rotor surface to smooth imperfections | Installing a brand-new brake rotor |

| Cost | Lower cost; saves money on parts | Higher cost; involves purchasing a new rotor |

| Time Required | Shorter repair time (typically 1-2 hours) | Moderate repair time (1-3 hours) |

| Effectiveness | Effective for minor surface damage and warping | Ideal for severely damaged or worn rotors |

| Durability | May reduce rotor thickness, shortening lifespan | Provides maximum lifespan with new material |

| Safety | Safe if rotor meets thickness specifications after resurfacing | Highest safety due to new component installation |

| Limitations | Not recommended if rotor thickness is below minimum | No significant limitations unless incompatible rotor |

Rotor Resurfacing vs Replacement: Key Differences

Rotor resurfacing restores the brake rotor's surface by removing minor grooves and uneven spots, extending rotor life and saving costs. Rotor replacement involves installing a new rotor, required when the rotor is too thin, warped, or severely damaged to safely resurface. Key differences include cost-effectiveness, time efficiency, and rotor thickness limits that dictate whether resurfacing is a viable option or replacement is necessary for optimal brake performance.

Signs Your Rotors Need Attention

Worn or warped rotors often cause vibrations or pulsations during braking, signaling the need for inspection. Deep grooves, scoring, or visible cracks on the rotor surface indicate resurfacing or replacement is necessary. If the rotor thickness falls below the manufacturer's minimum specification, replacement is the recommended solution to ensure optimal braking performance.

Pros and Cons of Rotor Resurfacing

Rotor resurfacing prolongs brake rotor life by smoothing out surface irregularities, providing a cost-effective alternative to rotor replacement and maintaining compatible thickness for proper braking performance. However, excessive material removal during resurfacing can reduce rotor thickness below safety standards, potentially causing heat retention and warping under heavy braking conditions. Limited effectiveness on severely damaged or warped rotors makes replacement necessary for optimal safety and performance in advanced wear scenarios.

Advantages and Disadvantages of Rotor Replacement

Rotor replacement offers improved braking performance by ensuring a perfectly smooth and defect-free surface, effectively eliminating issues caused by warped or excessively worn rotors. This method is more expensive and time-consuming compared to rotor resurfacing, and it requires careful selection to match vehicle specifications. However, replacement provides a longer-lasting solution that reduces the risk of brake system failures and enhances overall safety.

When Is Rotor Resurfacing Recommended?

Rotor resurfacing is recommended when the brake rotors have minor surface imperfections such as light scoring, glazing, or slight warping that can be smoothed out without compromising rotor thickness or structural integrity. It is best suited for rotors that meet the manufacturer's minimum thickness specifications and show no signs of deep cracks or significant corrosion. Choosing resurfacing over replacement can reduce costs and extend rotor lifespan when performed during routine brake maintenance.

Situations Where Rotor Replacement Is Necessary

Rotor replacement is necessary when rotors exhibit severe warping, deep grooves, or cracks that cannot be corrected through resurfacing. Excessive rotor thickness loss beyond manufacturer specifications compromises braking performance and safety, making replacement mandatory. In instances of consistent brake pulsation or vibration despite resurfacing attempts, rotor replacement ensures optimal vehicle stopping power.

Cost Comparison: Rotor Resurfacing vs Replacement

Rotor resurfacing typically costs between $10 to $25 per rotor, offering a budget-friendly option compared to rotor replacement which ranges from $30 to $75 per rotor or more depending on vehicle make and model. Resurfacing extends rotor life by smoothing surface irregularities, often saving 30% to 50% compared to full replacement costs while maintaining braking performance. However, frequent resurfacing may not be cost-effective if rotors are severely worn or below minimum thickness, making replacement the more reliable long-term investment.

Impact on Braking Performance and Safety

Rotor resurfacing restores a smooth braking surface, improving pad contact and maintaining effective braking performance, but may reduce rotor thickness, potentially compromising heat dissipation and safety under heavy use. Rotor replacement ensures optimal braking efficiency and safety by providing new, properly spec'd components free from wear or warping, which is critical for maintaining manufacturer-recommended rotor thickness and structural integrity. Choosing between resurfacing and replacement directly influences braking reliability, heat management, and overall vehicle safety during demanding driving conditions.

Longevity: Which Option Lasts Longer?

Rotor resurfacing extends the lifespan of brake rotors by removing surface imperfections and restoring a smooth braking surface, typically adding 1-2 years of service depending on rotor thickness and wear. Rotor replacement offers a longer lifespan, often lasting 30-50% more than resurfaced rotors, especially when wear is extensive or rotors are below the minimum thickness. Considering heat resistance, structural integrity, and long-term durability, replacement is generally the preferred option for maximizing longevity in vehicle braking systems.

Choosing the Right Service for Your Vehicle

Choosing between rotor resurfacing and rotor replacement depends on the severity of wear and your vehicle's brake system specifications. Rotor resurfacing is cost-effective for minor surface irregularities and extends rotor life, but replacement is necessary when rotors have deep grooves, warping, or are below minimum thickness. Ensuring optimal braking performance and safety requires assessing rotor condition with professional diagnostics before deciding on the appropriate service.

Rotor resurfacing vs rotor replacement Infographic

cardiffo.com

cardiffo.com