Patch welding offers a cost-effective solution for repairing localized damage by fusing metal patches directly onto the affected area, preserving the original panel and maintaining structural integrity. Panel replacement involves removing the entire damaged section and installing a new panel, which is often necessary for extensive corrosion or severe damage that compromises safety. Choosing between patch welding and panel replacement depends on the extent of the damage, budget constraints, and the desired longevity of the repair.

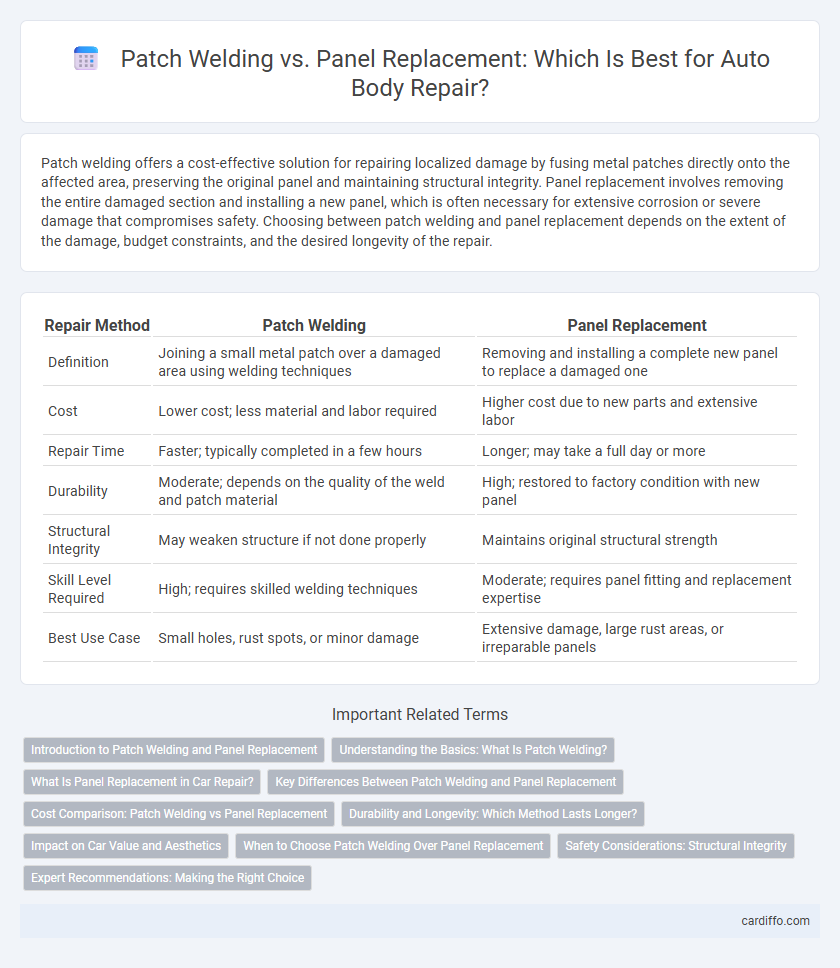

Table of Comparison

| Repair Method | Patch Welding | Panel Replacement |

|---|---|---|

| Definition | Joining a small metal patch over a damaged area using welding techniques | Removing and installing a complete new panel to replace a damaged one |

| Cost | Lower cost; less material and labor required | Higher cost due to new parts and extensive labor |

| Repair Time | Faster; typically completed in a few hours | Longer; may take a full day or more |

| Durability | Moderate; depends on the quality of the weld and patch material | High; restored to factory condition with new panel |

| Structural Integrity | May weaken structure if not done properly | Maintains original structural strength |

| Skill Level Required | High; requires skilled welding techniques | Moderate; requires panel fitting and replacement expertise |

| Best Use Case | Small holes, rust spots, or minor damage | Extensive damage, large rust areas, or irreparable panels |

Introduction to Patch Welding and Panel Replacement

Patch welding involves repairing damaged sections of a metal panel by welding a smaller piece directly onto the affected area, preserving the original structure and maintaining cost-effectiveness. Panel replacement entails removing and substituting an entire damaged panel, offering a more comprehensive solution for severe corrosion or structural damage. Both methods require skilled workmanship and assessment of damage extent to determine the most efficient and durable repair approach.

Understanding the Basics: What Is Patch Welding?

Patch welding involves applying a small metal patch over a damaged area on a vehicle's body to restore structural integrity and prevent rust or further damage. This technique is often used when only a localized section of a panel is compromised, offering a cost-effective and time-efficient alternative to full panel replacement. Patch welding requires precision to ensure strong adhesion and avoid distortion, making it essential for maintaining the vehicle's original shape and safety.

What Is Panel Replacement in Car Repair?

Panel replacement in car repair involves removing a damaged vehicle panel and installing a new or used one that matches the original specifications. This method restores structural integrity and appearance without extensive welding or reshaping. Panel replacement is often preferred for severe damage where patch welding cannot ensure long-term durability or aesthetic quality.

Key Differences Between Patch Welding and Panel Replacement

Patch welding involves repairing localized damage by welding a small section of metal directly onto the existing panel, preserving most of the original structure and typically reducing material costs and labor time. Panel replacement requires removing and installing an entire panel, ensuring structural integrity for severe damage but often increasing overall repair expenses and complexity. The key differences lie in the extent of damage addressed, cost-effectiveness, and restoration accuracy, with patch welding suitable for minor dents or rust and panel replacement preferred for extensive corrosion or impact damage.

Cost Comparison: Patch Welding vs Panel Replacement

Patch welding is generally more cost-effective than panel replacement because it requires fewer materials and less labor, making it the preferred choice for minor damage repairs. Panel replacement involves higher expenses due to the cost of a new panel and the extensive labor needed for removal, alignment, and installation. Choosing patch welding can significantly reduce repair costs while maintaining structural integrity, especially for localized damage.

Durability and Longevity: Which Method Lasts Longer?

Patch welding offers a durable repair by fusing new metal directly to the existing structure, maintaining the integrity and strength of the original panel. Panel replacement ensures longevity by completely removing damaged sections, preventing hidden rust and structural weaknesses that can compromise durability over time. Choosing between patch welding and panel replacement depends on the extent of damage and the desired lifespan of the repair.

Impact on Car Value and Aesthetics

Patch welding preserves more of the original metal, maintaining the car's structural integrity and potentially retaining higher resale value by avoiding major body alterations. Panel replacement can restore the vehicle's appearance to factory standards more quickly but may reduce value if the replacement panel does not match perfectly or shows signs of later repairs. For collectors and discerning buyers, visible welding marks or mismatched paint from patch repairs can negatively affect aesthetics and market price.

When to Choose Patch Welding Over Panel Replacement

Patch welding is ideal when the damaged area is localized and corrosion or rust is limited to a small section of the panel, preserving more of the original metal. It offers a cost-effective and time-efficient solution by avoiding the labor-intensive process of full panel replacement while maintaining structural integrity. Opt for patch welding when the surrounding metal is solid and the repair area is less than 50% of the panel's surface.

Safety Considerations: Structural Integrity

Patch welding preserves more of the original metal, maintaining consistent structural integrity and reducing the risk of weakening critical load-bearing areas. Panel replacement may introduce potential alignment issues and require precise welding to ensure the vehicle's frame remains safe under stress. Both methods demand strict adherence to manufacturer safety standards to guarantee optimal protection in the event of a collision.

Expert Recommendations: Making the Right Choice

Experts recommend patch welding for localized corrosion or small dents as it preserves the original panel integrity and saves costs. Panel replacement is advised when structural damage compromises vehicle safety or when extensive corrosion limits the feasibility of welding. Choosing the right method depends on factors such as damage severity, material type, and long-term durability considerations.

Patch welding vs panel replacement Infographic

cardiffo.com

cardiffo.com