Open-loop O2 sensors operate without feedback from the engine control unit (ECU), providing fixed readings that do not adjust fuel mixture based on exhaust gas content, typically used during engine warm-up or startup phases. Closed-loop O2 sensors continuously monitor the oxygen levels in the exhaust and send real-time data to the ECU, enabling precise adjustment of the air-fuel ratio for optimal combustion and emissions control. Repairing open-loop sensors often involves sensor replacement due to fixed calibration, while closed-loop sensor repairs may require sensor cleaning or circuit diagnostics to restore accurate feedback loops.

Table of Comparison

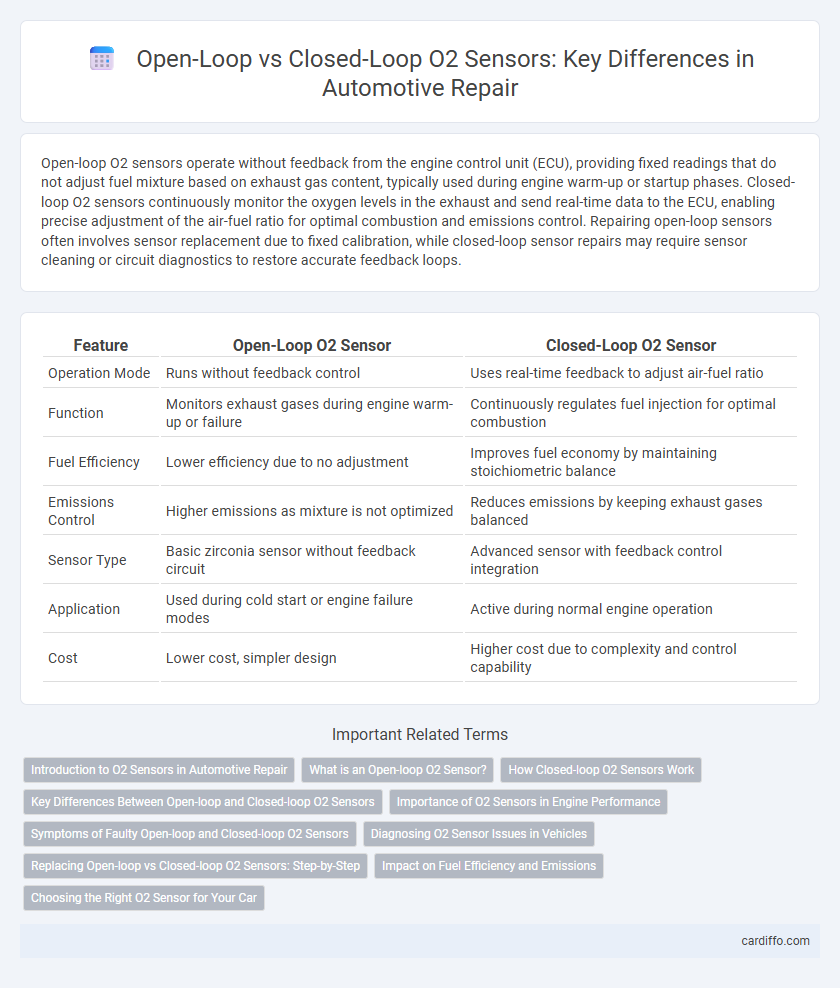

| Feature | Open-Loop O2 Sensor | Closed-Loop O2 Sensor |

|---|---|---|

| Operation Mode | Runs without feedback control | Uses real-time feedback to adjust air-fuel ratio |

| Function | Monitors exhaust gases during engine warm-up or failure | Continuously regulates fuel injection for optimal combustion |

| Fuel Efficiency | Lower efficiency due to no adjustment | Improves fuel economy by maintaining stoichiometric balance |

| Emissions Control | Higher emissions as mixture is not optimized | Reduces emissions by keeping exhaust gases balanced |

| Sensor Type | Basic zirconia sensor without feedback circuit | Advanced sensor with feedback control integration |

| Application | Used during cold start or engine failure modes | Active during normal engine operation |

| Cost | Lower cost, simpler design | Higher cost due to complexity and control capability |

Introduction to O2 Sensors in Automotive Repair

O2 sensors measure oxygen levels in exhaust gases to optimize engine performance and emissions control. Open-loop O2 sensors operate without feedback, primarily during cold starts or engine warm-up, while closed-loop O2 sensors continuously adjust fuel mixture based on real-time oxygen readings. Accurate diagnosis and replacement of faulty O2 sensors are essential for maintaining fuel efficiency and complying with emission standards in automotive repair.

What is an Open-loop O2 Sensor?

An open-loop O2 sensor operates without feedback control to the engine management system, typically during engine startup or heavy acceleration when the fuel mixture is preset and not adjusted based on oxygen levels in the exhaust. This sensor monitors oxygen content but its data is not used to regulate the air-fuel ratio, allowing the engine to run richer or leaner temporarily for performance or emissions reasons. Unlike closed-loop sensors, open-loop sensors provide raw oxygen readings without influencing the fuel injection system in real-time.

How Closed-loop O2 Sensors Work

Closed-loop O2 sensors continuously monitor exhaust gas oxygen levels and send real-time feedback to the engine control unit (ECU) to adjust the air-fuel mixture for optimal combustion efficiency. These sensors maintain precise control of the air-fuel ratio by detecting deviations from the ideal stoichiometric balance and enabling immediate corrections. Their rapid response helps reduce emissions, improve fuel economy, and enhance engine performance compared to the less responsive open-loop O2 sensors.

Key Differences Between Open-loop and Closed-loop O2 Sensors

Open-loop O2 sensors operate without feedback to the engine control unit (ECU), providing raw exhaust gas data primarily during engine warm-up or specific conditions. Closed-loop O2 sensors continuously send feedback to the ECU, enabling real-time adjustments to the air-fuel mixture for optimal combustion and emissions control. The key difference lies in feedback usage: open-loop sensors lack feedback mechanisms, while closed-loop sensors actively regulate engine performance for efficiency and reduced emissions.

Importance of O2 Sensors in Engine Performance

O2 sensors play a critical role in engine performance by continuously measuring the oxygen levels in the exhaust gases to optimize the air-fuel mixture. Open-loop O2 sensors provide initial data during engine warm-up but lack feedback control, while closed-loop O2 sensors enable real-time adjustments for fuel injection, improving fuel efficiency and reducing emissions. Precise oxygen measurement by closed-loop systems ensures optimal combustion, preventing engine damage and maintaining regulatory compliance.

Symptoms of Faulty Open-loop and Closed-loop O2 Sensors

Faulty open-loop O2 sensors often cause poor fuel economy, rough engine idle, and increased emissions due to improper air-fuel mixture control. Closed-loop O2 sensor failures typically result in check engine light activation, hesitation during acceleration, and failed emissions tests as the engine control unit cannot accurately adjust fuel delivery. Both sensor issues can lead to engine performance problems, but open-loop sensor faults predominantly affect fuel delivery during cold starts, while closed-loop sensor defects impact ongoing engine operation.

Diagnosing O2 Sensor Issues in Vehicles

Open-loop O2 sensors operate without feedback, delivering raw air-fuel ratio data, making them less precise for diagnosing engine performance issues compared to closed-loop O2 sensors. Closed-loop O2 sensors continuously monitor exhaust oxygen levels and adjust fuel injection in real-time, providing accurate data crucial for identifying faulty sensors or incorrect fuel mixture. Diagnosing O2 sensor issues involves analyzing voltage fluctuations and response times, with closed-loop sensors offering detailed feedback essential for pinpointing sensor degradation or wiring problems.

Replacing Open-loop vs Closed-loop O2 Sensors: Step-by-Step

Replacing open-loop O2 sensors involves disconnecting sensor wires, removing the old sensor with an oxygen sensor socket, and installing the new sensor without relying on feedback for fuel adjustments. Closed-loop O2 sensor replacement requires careful handling of sensor connectors and ensuring the new sensor is compatible with the vehicle's ECU for precise fuel mixture regulation. Proper diagnosis before replacement ensures optimal engine performance and reduced emissions.

Impact on Fuel Efficiency and Emissions

Open-loop O2 sensors provide limited feedback to the engine control unit, resulting in less precise air-fuel mixture adjustments that can lead to increased fuel consumption and higher emissions. Closed-loop O2 sensors continuously monitor exhaust gases, enabling real-time air-fuel ratio optimization that significantly improves fuel efficiency and reduces harmful emissions. Modern vehicles rely on closed-loop O2 sensors to meet stringent emission standards and enhance overall engine performance.

Choosing the Right O2 Sensor for Your Car

Choosing the right O2 sensor for your car depends on the engine control system: open-loop sensors provide basic air-fuel mixture data during engine warm-up or failure conditions, while closed-loop sensors deliver precise feedback for optimal fuel efficiency and emissions control under normal operation. Matching the sensor type to your vehicle's ECU is critical, as closed-loop sensors continuously adjust fuel delivery based on real-time oxygen levels in the exhaust. Installing the appropriate O2 sensor ensures accurate engine performance, reduced emissions, and compliance with emission standards.

Open-loop O2 sensor vs Closed-loop O2 sensor Infographic

cardiffo.com

cardiffo.com