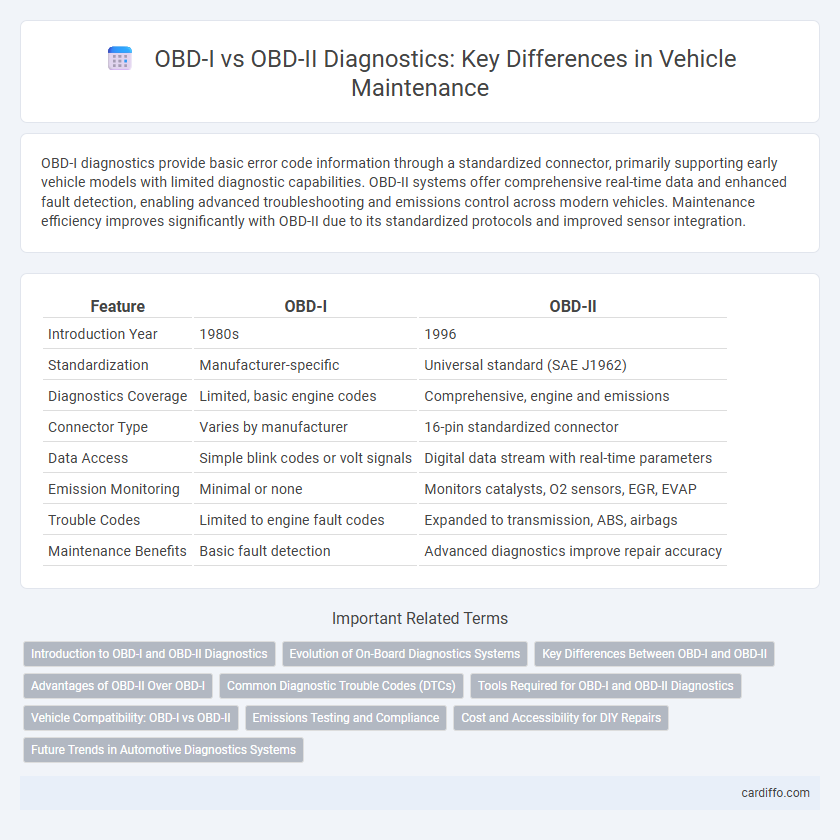

OBD-I diagnostics provide basic error code information through a standardized connector, primarily supporting early vehicle models with limited diagnostic capabilities. OBD-II systems offer comprehensive real-time data and enhanced fault detection, enabling advanced troubleshooting and emissions control across modern vehicles. Maintenance efficiency improves significantly with OBD-II due to its standardized protocols and improved sensor integration.

Table of Comparison

| Feature | OBD-I | OBD-II |

|---|---|---|

| Introduction Year | 1980s | 1996 |

| Standardization | Manufacturer-specific | Universal standard (SAE J1962) |

| Diagnostics Coverage | Limited, basic engine codes | Comprehensive, engine and emissions |

| Connector Type | Varies by manufacturer | 16-pin standardized connector |

| Data Access | Simple blink codes or volt signals | Digital data stream with real-time parameters |

| Emission Monitoring | Minimal or none | Monitors catalysts, O2 sensors, EGR, EVAP |

| Trouble Codes | Limited to engine fault codes | Expanded to transmission, ABS, airbags |

| Maintenance Benefits | Basic fault detection | Advanced diagnostics improve repair accuracy |

Introduction to OBD-I and OBD-II Diagnostics

OBD-I diagnostics, introduced in the early 1980s, provided basic vehicle emissions monitoring through proprietary systems unique to each manufacturer, limiting standardized troubleshooting. OBD-II, mandated in 1996, offers comprehensive diagnostics with standardized trouble codes and real-time data accessible via a universal connector, enhancing accuracy in identifying engine and emissions-related issues. The transition from OBD-I to OBD-II represents a significant evolution in vehicle maintenance technology, enabling more effective diagnostics and repair strategies across various makes and models.

Evolution of On-Board Diagnostics Systems

OBD-I systems, introduced in the early 1980s, provided basic engine diagnostics with limited standardized data, primarily focusing on emission controls. The transition to OBD-II in 1996 brought enhanced diagnostics through standardized connectors, real-time data access, and expanded fault code coverage, enabling more accurate emissions monitoring and vehicle performance analysis. Modern OBD-II systems integrate advanced sensors and communication protocols, improving maintenance precision and reducing environmental impact by facilitating early detection of engine issues.

Key Differences Between OBD-I and OBD-II

OBD-I and OBD-II diagnostics differ primarily in data standardization and functionality, with OBD-II offering uniform diagnostic trouble codes (DTCs) and enhanced real-time monitoring across all vehicles manufactured after 1996. OBD-II systems provide comprehensive data access through a standardized 16-pin connector, supporting more advanced emission control diagnostics and readiness monitors compared to the vehicle-specific, less sophisticated protocols of OBD-I. Technicians benefit from OBD-II's improved fault detection and data logging capabilities, facilitating faster and more accurate maintenance and repair processes.

Advantages of OBD-II Over OBD-I

OBD-II diagnostics provide comprehensive real-time data and standardized trouble codes, enabling faster and more accurate vehicle maintenance compared to OBD-I. Enhanced communication protocols and expanded sensor coverage allow OBD-II systems to detect a broader range of issues, improving emissions control and fuel efficiency. The universal compatibility of OBD-II ensures easier access to diagnostic tools and supports advanced monitoring features not available in OBD-I systems.

Common Diagnostic Trouble Codes (DTCs)

OBD-I diagnostics, used primarily in vehicles from 1981 to 1995, feature manufacturer-specific trouble codes that often require specialized tools and reference materials for accurate interpretation. OBD-II, standardized in 1996, uses a universal set of Diagnostic Trouble Codes (DTCs) that streamline fault identification across all vehicle makes, including common codes like P0171 (System Too Lean) and P0420 (Catalyst System Efficiency Below Threshold). The transition to OBD-II improved maintenance efficiency by providing standardized fault codes, enabling quicker and more accurate diagnostics with generic scan tools.

Tools Required for OBD-I and OBD-II Diagnostics

OBD-I diagnostics typically require basic handheld code readers or manual jumper wire tools to access the vehicle's diagnostic data, often involving physical pin bridges or blinking light codes. OBD-II diagnostics demand more advanced scan tools with standardized connectors and software capable of reading comprehensive fault codes, real-time sensor data, and emission system performance. Modern OBD-II scanners support extended protocols like CAN, ISO 9141, and KWP2000, enabling detailed engine and emissions troubleshooting beyond the capabilities of OBD-I tools.

Vehicle Compatibility: OBD-I vs OBD-II

OBD-I diagnostics are compatible primarily with vehicles manufactured between 1981 and 1995, using manufacturer-specific protocols that vary between car makers. OBD-II systems, standardized in 1996 and later models, support a universal protocol across all makes and models in the United States, enabling comprehensive diagnostics and emissions monitoring. The transition to OBD-II enhances vehicle compatibility by offering consistent real-time data and standardized trouble codes applicable to a wider range of vehicles.

Emissions Testing and Compliance

OBD-II diagnostics provide more comprehensive emissions testing and compliance capabilities compared to OBD-I, featuring standardized protocols and enhanced sensor data that enable precise detection of emissions-related malfunctions. OBD-II systems monitor a wider range of emission control components and store detailed trouble codes, facilitating accurate repairs and regulatory adherence. The improved data accuracy and standardized communication in OBD-II help ensure vehicles meet stricter environmental standards and pass emissions inspections reliably.

Cost and Accessibility for DIY Repairs

OBD-I systems are generally less expensive to diagnose due to their simpler architecture and limited sensor data, making basic repairs more accessible for DIY enthusiasts. OBD-II provides a standardized diagnostic protocol that offers more comprehensive information but often requires advanced scan tools, which can increase initial costs and complexity for home mechanics. Despite higher upfront expenses, OBD-II's broad compatibility with affordable code readers enhances long-term accessibility and effective troubleshooting for DIY maintenance.

Future Trends in Automotive Diagnostics Systems

Future trends in automotive diagnostics systems emphasize enhanced connectivity and real-time data analysis, surpassing the capabilities of OBD-I and OBD-II protocols. Advanced onboard diagnostics integrate with telematics and cloud computing to enable predictive maintenance and remote troubleshooting. Increased use of artificial intelligence and machine learning algorithms improves fault detection accuracy and supports autonomous vehicle systems.

OBD-I vs OBD-II diagnostics Infographic

cardiffo.com

cardiffo.com