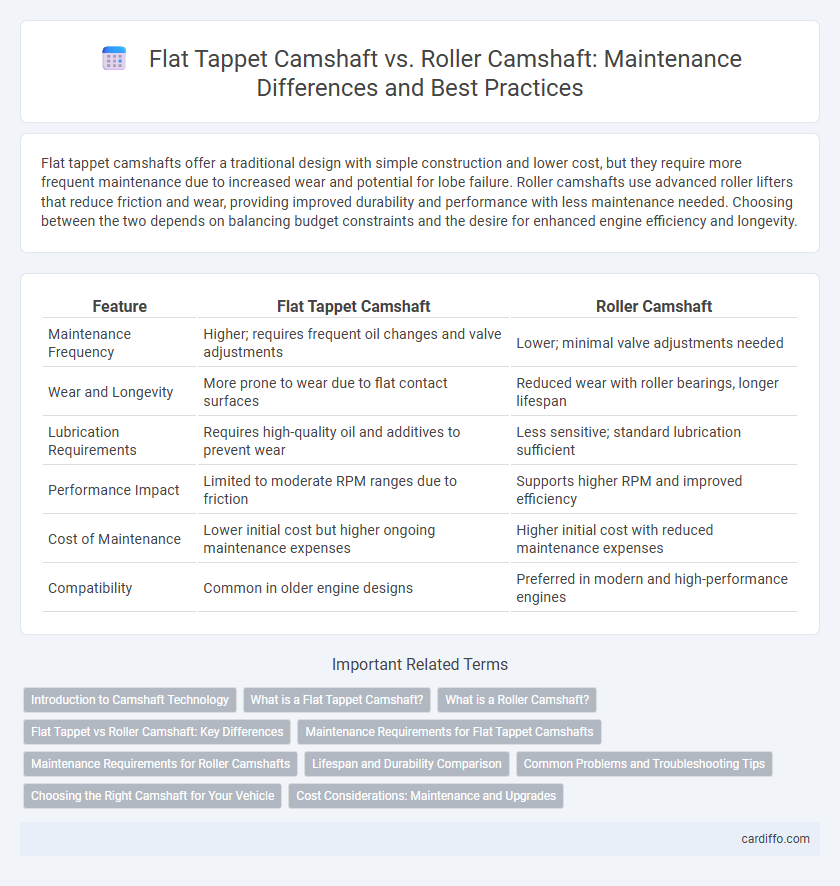

Flat tappet camshafts offer a traditional design with simple construction and lower cost, but they require more frequent maintenance due to increased wear and potential for lobe failure. Roller camshafts use advanced roller lifters that reduce friction and wear, providing improved durability and performance with less maintenance needed. Choosing between the two depends on balancing budget constraints and the desire for enhanced engine efficiency and longevity.

Table of Comparison

| Feature | Flat Tappet Camshaft | Roller Camshaft |

|---|---|---|

| Maintenance Frequency | Higher; requires frequent oil changes and valve adjustments | Lower; minimal valve adjustments needed |

| Wear and Longevity | More prone to wear due to flat contact surfaces | Reduced wear with roller bearings, longer lifespan |

| Lubrication Requirements | Requires high-quality oil and additives to prevent wear | Less sensitive; standard lubrication sufficient |

| Performance Impact | Limited to moderate RPM ranges due to friction | Supports higher RPM and improved efficiency |

| Cost of Maintenance | Lower initial cost but higher ongoing maintenance expenses | Higher initial cost with reduced maintenance expenses |

| Compatibility | Common in older engine designs | Preferred in modern and high-performance engines |

Introduction to Camshaft Technology

Flat tappet camshafts utilize a sliding action between the cam lobe and lifter, relying heavily on oil lubrication to reduce wear, making precise maintenance critical to prevent premature failure. Roller camshafts employ roller bearings to minimize friction and wear, offering improved durability and performance with less frequent maintenance intervals. Understanding the distinct lubrication and mechanical requirements of each camshaft type is essential for optimizing engine longevity and functionality.

What is a Flat Tappet Camshaft?

A flat tappet camshaft uses flat-faced lifters that slide directly on the camshaft lobes, requiring precise lubrication and regular maintenance to prevent wear. Its simple design provides reliable performance in older engines but tends to wear faster compared to roller camshafts. Proper oiling and timely inspection are crucial to extend the lifespan of flat tappet camshaft components.

What is a Roller Camshaft?

A roller camshaft uses roller bearings on its cam lobes, significantly reducing friction compared to flat tappet camshafts. This design improves longevity and efficiency by minimizing wear and heat buildup during engine operation. Roller camshafts provide smoother valve actuation and are preferred for high-performance and modern engines.

Flat Tappet vs Roller Camshaft: Key Differences

Flat tappet camshafts feature lifters that slide directly on the cam lobes, resulting in increased wear and requiring frequent oil changes and precise maintenance to prevent premature failure. Roller camshafts utilize lifters with rollers that reduce friction and wear, improving durability and allowing for more aggressive cam profiles with less maintenance demands. The key differences between flat tappet and roller camshafts impact maintenance schedules, camshaft longevity, and overall engine performance.

Maintenance Requirements for Flat Tappet Camshafts

Flat tappet camshafts require regular maintenance, including frequent oil changes with high-zinc content oil to prevent excessive wear on lifters and cam lobes. Proper break-in procedures are critical during installation to ensure longevity and avoid premature failure. Compared to roller camshafts, flat tappets demand more diligent lubrication monitoring and increased valve lash adjustments to maintain optimal engine performance.

Maintenance Requirements for Roller Camshafts

Roller camshafts demand less frequent maintenance compared to flat tappet camshafts due to reduced friction and wear from their rolling followers. They require routine lubrication checks with high-quality oils containing adequate anti-wear additives to ensure longevity. Proper valve lash adjustment is crucial, though roller camshafts generally exhibit greater resistance to lobe wear, making them more durable in high-performance applications.

Lifespan and Durability Comparison

Flat tappet camshafts generally have a shorter lifespan due to their higher friction and increased wear, often requiring more frequent maintenance or replacement. Roller camshafts feature hardened rollers that reduce friction and wear, significantly enhancing durability and extending the camshaft's operational life. Engine performance and longevity benefit from roller camshafts' superior resistance to wear under high-load conditions.

Common Problems and Troubleshooting Tips

Flat tappet camshafts commonly suffer from premature wear and scoring due to insufficient lubrication, leading to valve timing issues and decreased engine performance. Roller camshafts, while more durable, can experience problems like bearing failure and roller tip wear, which often result from improper assembly or lack of maintenance. Regular inspection of oil quality, camshaft lobes, and lifters, along with timely replacement of worn components, helps prevent common issues and ensures optimal engine functionality.

Choosing the Right Camshaft for Your Vehicle

Choosing the right camshaft for your vehicle depends on factors such as performance goals, engine type, and maintenance preferences. Flat tappet camshafts offer simplicity and affordability but require precise oiling and regular valve adjusting, while roller camshafts provide improved durability and higher RPM capability with reduced wear. Selecting a roller camshaft enhances engine efficiency and longevity, especially in high-performance or modern vehicles demanding advanced valve train technology.

Cost Considerations: Maintenance and Upgrades

Flat tappet camshafts generally incur lower initial costs but demand more frequent maintenance and timely oil changes to prevent premature wear, increasing long-term expenses. Roller camshafts, while more expensive upfront, offer enhanced durability and reduced friction, leading to fewer maintenance needs and potentially lower overall lifecycle costs. Upgrading to a roller camshaft can improve engine efficiency and longevity, justifying the higher initial investment despite the cost difference.

Flat Tappet Camshaft vs Roller Camshaft Infographic

cardiffo.com

cardiffo.com