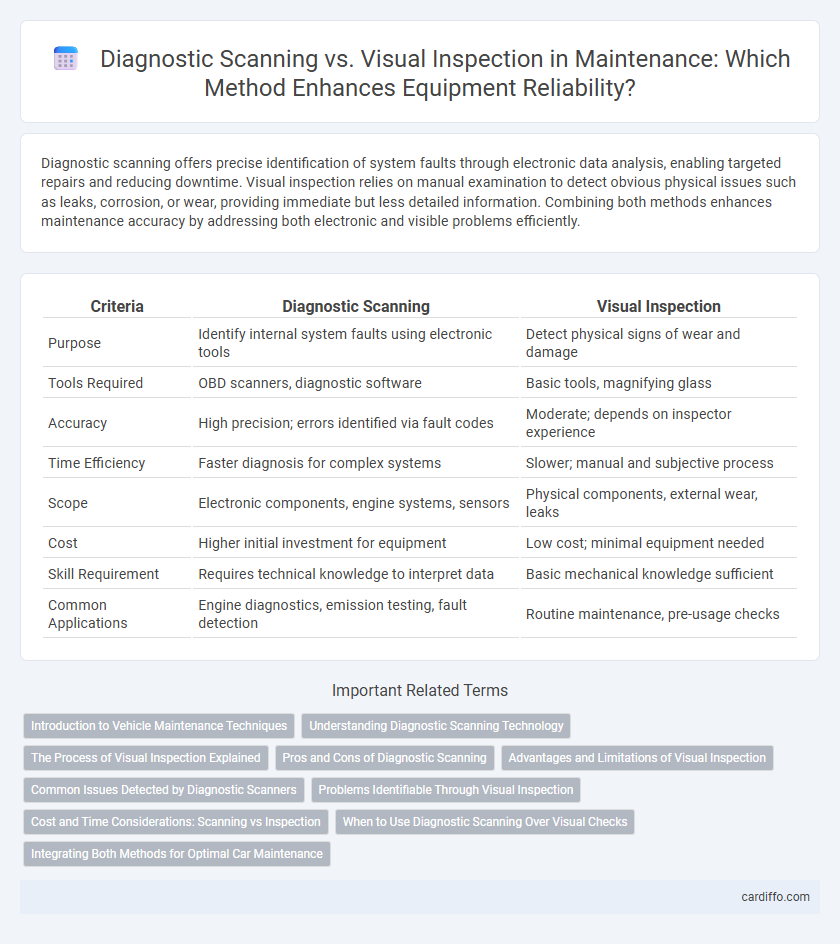

Diagnostic scanning offers precise identification of system faults through electronic data analysis, enabling targeted repairs and reducing downtime. Visual inspection relies on manual examination to detect obvious physical issues such as leaks, corrosion, or wear, providing immediate but less detailed information. Combining both methods enhances maintenance accuracy by addressing both electronic and visible problems efficiently.

Table of Comparison

| Criteria | Diagnostic Scanning | Visual Inspection |

|---|---|---|

| Purpose | Identify internal system faults using electronic tools | Detect physical signs of wear and damage |

| Tools Required | OBD scanners, diagnostic software | Basic tools, magnifying glass |

| Accuracy | High precision; errors identified via fault codes | Moderate; depends on inspector experience |

| Time Efficiency | Faster diagnosis for complex systems | Slower; manual and subjective process |

| Scope | Electronic components, engine systems, sensors | Physical components, external wear, leaks |

| Cost | Higher initial investment for equipment | Low cost; minimal equipment needed |

| Skill Requirement | Requires technical knowledge to interpret data | Basic mechanical knowledge sufficient |

| Common Applications | Engine diagnostics, emission testing, fault detection | Routine maintenance, pre-usage checks |

Introduction to Vehicle Maintenance Techniques

Diagnostic scanning utilizes advanced electronic tools to read fault codes from a vehicle's onboard computer, enabling precise identification of issues within complex systems like the engine, transmission, and ABS. Visual inspection involves physically examining vehicle components such as belts, hoses, brakes, and fluid levels to detect wear, leaks, or damage without requiring specialized equipment. Combining both techniques enhances diagnostic accuracy and supports comprehensive preventative maintenance for improved vehicle reliability and performance.

Understanding Diagnostic Scanning Technology

Diagnostic scanning technology utilizes advanced sensors and software to quickly identify faults in complex machinery by analyzing electronic signals and system data, offering precise and real-time fault detection. Visual inspection, while useful for surface-level issues, lacks the capability to detect underlying electronic or software malfunctions that diagnostic scanning can reveal. Understanding diagnostic scanning enables maintenance professionals to predict failures accurately and streamline repair processes, reducing downtime and enhancing machinery reliability.

The Process of Visual Inspection Explained

Visual inspection involves a systematic examination of equipment or machinery to identify visible signs of wear, damage, or abnormalities. This process typically includes checking for cracks, leaks, corrosion, misalignments, and other defects using the naked eye or basic tools such as magnifying glasses and borescopes. Visual inspection serves as a critical frontline method in maintenance routines, helping to prevent major failures by detecting issues early before they manifest in system diagnostics.

Pros and Cons of Diagnostic Scanning

Diagnostic scanning offers precise fault identification by accessing vehicle onboard computer systems, enabling swift and accurate diagnosis of complex issues that may be missed during visual inspection. However, reliance on diagnostic tools can lead to overlooking obvious mechanical problems visible externally, and equipment costs and required technical expertise may limit its accessibility. Despite these drawbacks, diagnostic scanning significantly enhances troubleshooting efficiency and accuracy in modern maintenance practices.

Advantages and Limitations of Visual Inspection

Visual inspection offers a quick, cost-effective method for detecting surface-level defects and obvious wear in maintenance routines, enabling rapid identification of issues without specialized equipment. However, its limitations include an inability to detect subsurface or internal faults, reliance on inspector expertise, and susceptibility to human error and environmental conditions, which may result in missed or inaccurate diagnoses. While valuable for routine checks, visual inspection should be complemented with diagnostic scanning to ensure comprehensive equipment assessment.

Common Issues Detected by Diagnostic Scanners

Diagnostic scanners efficiently identify engine misfires, faulty oxygen sensors, and transmission problems by reading error codes from the vehicle's computer system. These tools detect issues invisible to the naked eye, such as malfunctioning fuel injectors, sensor failures, and emission control system faults. Visual inspection, while useful for spotting leaks, worn belts, or corrosion, cannot match the precise fault identification provided by diagnostic scanning technology.

Problems Identifiable Through Visual Inspection

Visual inspection effectively identifies surface-level issues such as corrosion, leaks, cracks, and misalignments in mechanical components. It detects obvious wear and tear, color changes, deformation, and physical damage without requiring specialized equipment. This method quickly highlights safety hazards and deteriorations impacting operational reliability, enabling prompt corrective maintenance.

Cost and Time Considerations: Scanning vs Inspection

Diagnostic scanning reduces overall maintenance costs by quickly identifying hidden issues, minimizing downtime and labor expenses compared to traditional visual inspection. Visual inspection, while less costly upfront, is time-consuming and may miss critical faults, leading to expensive repairs later. Employing diagnostic scanning optimizes maintenance schedules and resource allocation, delivering long-term savings and improved operational efficiency.

When to Use Diagnostic Scanning Over Visual Checks

Diagnostic scanning is preferred over visual inspection when dealing with complex electronic systems or when fault codes and performance data are necessary to pinpoint issues accurately. It is especially useful for modern vehicles or machinery equipped with onboard computers and sensors that cannot be assessed through visual checks alone. Diagnostic tools provide real-time information on system health, enabling targeted repairs and reducing downtime.

Integrating Both Methods for Optimal Car Maintenance

Integrating diagnostic scanning with visual inspection enhances car maintenance by combining advanced electronic system analysis and hands-on physical evaluation. Diagnostic scanners quickly identify concealed faults within the engine control units and sensor networks, while visual inspections detect wear, leaks, and corrosion not evident in digital readouts. This dual approach maximizes accuracy, reduces repair costs, and extends vehicle longevity by addressing both electronic and mechanical issues promptly.

Diagnostic Scanning vs Visual Inspection Infographic

cardiffo.com

cardiffo.com