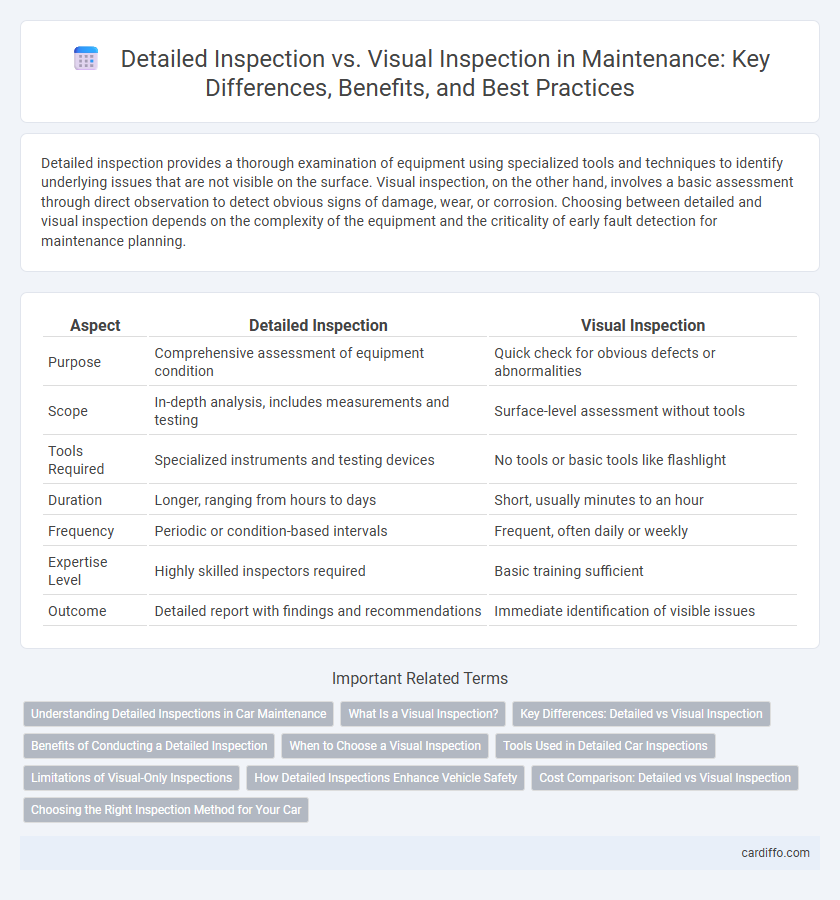

Detailed inspection provides a thorough examination of equipment using specialized tools and techniques to identify underlying issues that are not visible on the surface. Visual inspection, on the other hand, involves a basic assessment through direct observation to detect obvious signs of damage, wear, or corrosion. Choosing between detailed and visual inspection depends on the complexity of the equipment and the criticality of early fault detection for maintenance planning.

Table of Comparison

| Aspect | Detailed Inspection | Visual Inspection |

|---|---|---|

| Purpose | Comprehensive assessment of equipment condition | Quick check for obvious defects or abnormalities |

| Scope | In-depth analysis, includes measurements and testing | Surface-level assessment without tools |

| Tools Required | Specialized instruments and testing devices | No tools or basic tools like flashlight |

| Duration | Longer, ranging from hours to days | Short, usually minutes to an hour |

| Frequency | Periodic or condition-based intervals | Frequent, often daily or weekly |

| Expertise Level | Highly skilled inspectors required | Basic training sufficient |

| Outcome | Detailed report with findings and recommendations | Immediate identification of visible issues |

Understanding Detailed Inspections in Car Maintenance

Detailed inspections in car maintenance involve thorough examination of critical components, including engine systems, brake conditions, and suspension integrity, ensuring early detection of potential issues that visual inspections might miss. These inspections utilize specialized diagnostic tools and protocols to assess wear, corrosion, and mechanical performance beyond surface-level observations. Understanding detailed inspections helps maintain vehicle safety, prolong lifespan, and optimize performance by addressing hidden defects before they lead to costly repairs.

What Is a Visual Inspection?

A visual inspection involves examining equipment or structures with the naked eye or basic tools to identify obvious defects such as corrosion, cracks, or leaks. It serves as a preliminary assessment method that can be performed quickly and frequently without specialized training. This process helps detect surface-level issues early, enabling timely maintenance and preventing more severe failures.

Key Differences: Detailed vs Visual Inspection

Detailed inspection involves an in-depth examination using specialized tools and techniques to identify potential defects not visible to the naked eye, ensuring thorough assessment of components. Visual inspection relies on unaided observation, detecting obvious surface anomalies such as cracks, corrosion, or misalignment with minimal equipment. The key difference lies in the level of precision and methodology, with detailed inspection providing comprehensive diagnostics, whereas visual inspection offers a quick, initial evaluation.

Benefits of Conducting a Detailed Inspection

Conducting a detailed inspection in maintenance uncovers hidden defects and wear that visual inspection often misses, ensuring early detection of potential failures and reducing unexpected downtime. Detailed inspections utilize advanced diagnostic tools and techniques that provide comprehensive data on equipment condition, enhancing predictive maintenance strategies. This thorough approach increases asset lifespan and optimizes operational efficiency by addressing issues before they escalate into costly repairs.

When to Choose a Visual Inspection

Visual inspection is ideal for routine maintenance when quick, non-invasive checks are sufficient to detect obvious defects or wear, such as surface corrosion, leaks, or misalignment. Choose visual inspection during frequent intervals or when equipment downtime must be minimized, as it requires no special tools and provides immediate feedback. Detailed inspection is reserved for complex issues or when initial visual checks indicate potential internal damage or safety concerns needing in-depth analysis.

Tools Used in Detailed Car Inspections

Detailed car inspections employ advanced diagnostic tools such as electronic scan tools, infrared cameras, and ultrasonic testers to detect hidden defects and ensure comprehensive evaluation. Visual inspections primarily rely on basic hand tools and direct observation, limiting their capacity to identify internal or electronic issues. Utilizing specialized equipment in detailed inspections enhances accuracy, enabling early detection of mechanical, electrical, and structural problems that visual inspections might overlook.

Limitations of Visual-Only Inspections

Visual-only inspections often fail to detect subsurface cracks, corrosion, or internal wear, limiting their reliability in critical maintenance scenarios. Detailed inspections utilize advanced techniques such as ultrasonic testing, radiography, or dye penetrant methods to identify flaws invisible to the naked eye. Relying solely on visual inspections increases the risk of undetected damage, potentially leading to unexpected equipment failures and costly downtime.

How Detailed Inspections Enhance Vehicle Safety

Detailed inspections involve comprehensive checks of critical vehicle components, uncovering hidden issues that visual inspections might miss. By examining engine systems, brake functionality, and suspension integrity at a granular level, detailed inspections significantly reduce the risk of mechanical failure. This thorough approach enhances vehicle safety by ensuring early detection and timely repair of potential hazards.

Cost Comparison: Detailed vs Visual Inspection

Detailed inspections incur higher costs than visual inspections due to the use of specialized tools, advanced techniques, and extended labor hours. Visual inspections are more cost-effective as they rely on basic observational methods and require less time and fewer resources. Organizations often balance inspection rigor with budget constraints, choosing visual inspections for routine checks and detailed inspections for critical or complex maintenance tasks.

Choosing the Right Inspection Method for Your Car

Detailed inspection involves thorough examination using specialized tools to identify hidden issues in critical components, ensuring comprehensive diagnostics for your car's maintenance. Visual inspection relies on a surface-level assessment to detect obvious defects, suitable for routine checks or minor issues but less effective for detecting internal or developing problems. Selecting the right inspection method depends on the car's age, condition, and maintenance history, with detailed inspections recommended for high-mileage or complex systems and visual inspections adequate for regular preventive care.

Detailed Inspection vs Visual Inspection Infographic

cardiffo.com

cardiffo.com