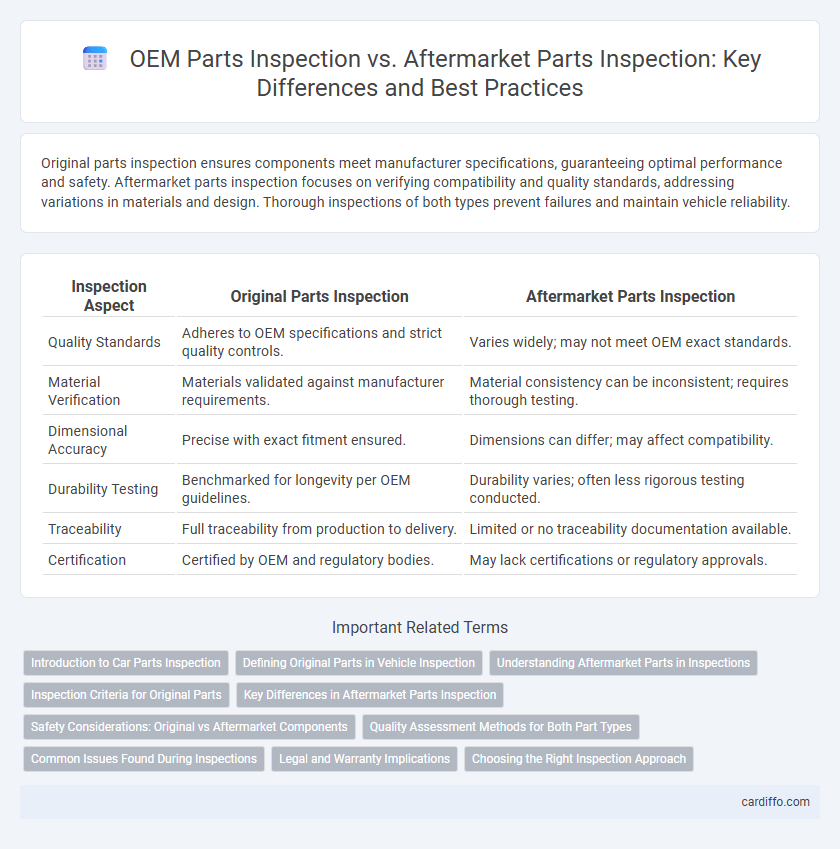

Original parts inspection ensures components meet manufacturer specifications, guaranteeing optimal performance and safety. Aftermarket parts inspection focuses on verifying compatibility and quality standards, addressing variations in materials and design. Thorough inspections of both types prevent failures and maintain vehicle reliability.

Table of Comparison

| Inspection Aspect | Original Parts Inspection | Aftermarket Parts Inspection |

|---|---|---|

| Quality Standards | Adheres to OEM specifications and strict quality controls. | Varies widely; may not meet OEM exact standards. |

| Material Verification | Materials validated against manufacturer requirements. | Material consistency can be inconsistent; requires thorough testing. |

| Dimensional Accuracy | Precise with exact fitment ensured. | Dimensions can differ; may affect compatibility. |

| Durability Testing | Benchmarked for longevity per OEM guidelines. | Durability varies; often less rigorous testing conducted. |

| Traceability | Full traceability from production to delivery. | Limited or no traceability documentation available. |

| Certification | Certified by OEM and regulatory bodies. | May lack certifications or regulatory approvals. |

Introduction to Car Parts Inspection

Car parts inspection involves verifying the quality and authenticity of components to ensure vehicle safety and performance. Original parts inspection focuses on OEM (Original Equipment Manufacturer) components, known for strict adherence to manufacturer specifications and durability standards. Aftermarket parts inspection evaluates compatibility, quality, and safety of non-OEM components, which vary widely in manufacturing standards and material composition.

Defining Original Parts in Vehicle Inspection

Original parts in vehicle inspection are components manufactured by the vehicle's original equipment manufacturer (OEM) and conform to strict quality and safety standards. These parts ensure compatibility, reliability, and maintain the vehicle's warranty, unlike aftermarket parts which vary in quality and specifications. Thorough inspection of original parts involves verifying serial numbers, OEM markings, and material integrity to guarantee authenticity and performance.

Understanding Aftermarket Parts in Inspections

Aftermarket parts inspection requires a thorough understanding of quality variations compared to original parts, emphasizing material composition, durability, and fitment standards. Inspectors must verify compliance with industry specifications and regulatory requirements to ensure safety and performance equivalence. Accurate identification and documentation of aftermarket parts help maintain equipment reliability and warranty integrity during inspections.

Inspection Criteria for Original Parts

Inspection criteria for original parts emphasize strict adherence to manufacturer specifications, ensuring dimensional accuracy, material composition, and surface finish meet certified standards. Quality control involves thorough testing using calibrated instruments to verify functionality and durability, reflecting performance parameters established by the original equipment manufacturer (OEM). Traceability documentation and certification further validate the authenticity and compliance of original parts in comparison to aftermarket alternatives.

Key Differences in Aftermarket Parts Inspection

Aftermarket parts inspection involves unique challenges such as verifying compatibility, quality consistency, and compliance with industry standards, which are less critical in original parts inspection due to manufacturer-controlled production. Aftermarket parts often require rigorous testing for fit, material integrity, and performance reliability to prevent potential failures. Inspection protocols emphasize detecting counterfeit parts and ensuring traceability to maintain safety and functionality standards.

Safety Considerations: Original vs Aftermarket Components

Original parts inspection ensures compliance with manufacturer safety standards, maintaining vehicle integrity and reducing the risk of failure during operation. Aftermarket parts inspection requires rigorous verification against OEM specifications to identify potential deviations that could compromise structural strength or functionality. Safety considerations emphasize the critical importance of authentic materials and design precision inherent in original components versus the variability found in aftermarket substitutes.

Quality Assessment Methods for Both Part Types

Quality assessment methods for original parts inspection prioritize strict adherence to OEM specifications using precision measurement tools and advanced nondestructive testing techniques. Aftermarket parts inspection involves comprehensive compatibility and performance evaluations, including material composition analysis and durability testing to ensure equivalency with original equipment standards. Statistical process control and failure mode analysis are critical for maintaining quality consistency across both part types.

Common Issues Found During Inspections

Common issues found during original parts inspection include manufacturing defects, warranty compliance problems, and material inconsistencies. Aftermarket parts inspections frequently reveal compatibility mismatches, substandard materials, and deviations from OEM specifications. Both inspection processes emphasize the importance of verifying authenticity and quality to ensure safety and performance standards are met.

Legal and Warranty Implications

Original parts inspection ensures compliance with manufacturer specifications, minimizing legal risks associated with counterfeit or substandard components. Aftermarket parts inspection requires rigorous verification to avoid warranty voidance and potential liability issues stemming from non-certified materials. Accurate documentation during both inspections supports legal defense and maintains warranty validity.

Choosing the Right Inspection Approach

Choosing the right inspection approach hinges on the specific requirements of original parts versus aftermarket parts, where original parts inspection prioritizes adherence to OEM standards and traceability to ensure authenticity. Aftermarket parts inspection requires a rigorous evaluation of material quality, fit, and performance compatibility to prevent safety risks and warranty issues. Implementing advanced non-destructive testing and dimensional analysis tailored to the part's source enhances accuracy and reliability in quality assurance processes.

Original parts inspection vs aftermarket parts inspection Infographic

cardiffo.com

cardiffo.com