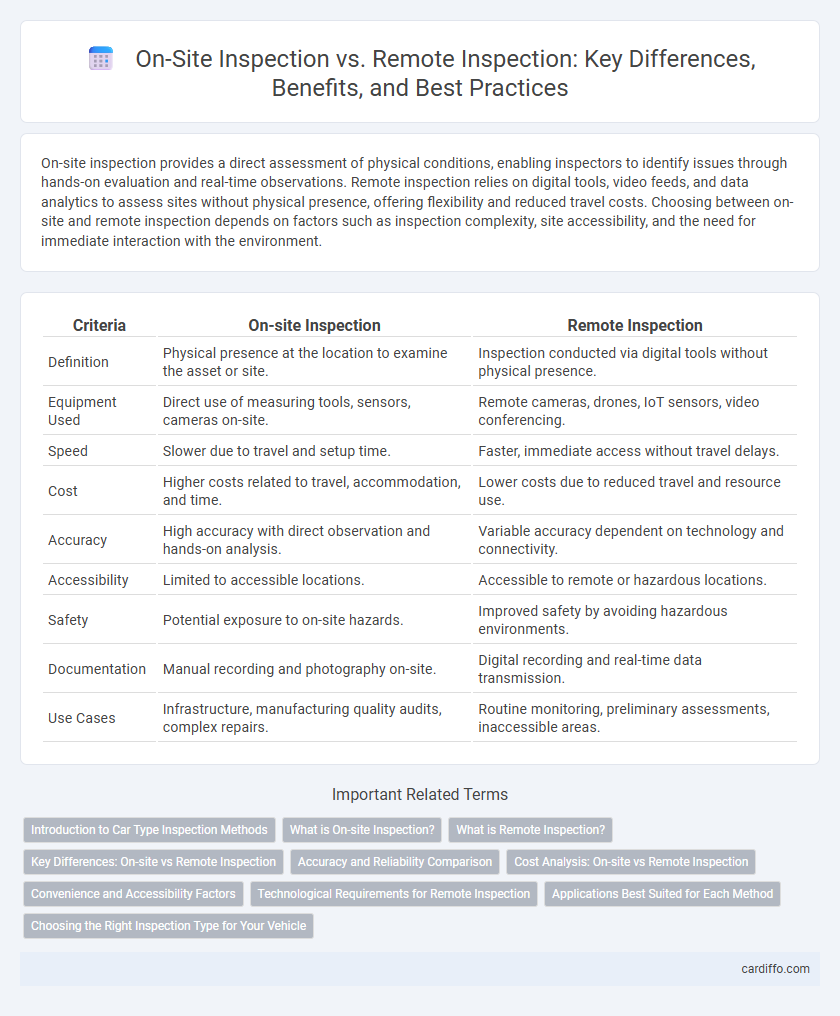

On-site inspection provides a direct assessment of physical conditions, enabling inspectors to identify issues through hands-on evaluation and real-time observations. Remote inspection relies on digital tools, video feeds, and data analytics to assess sites without physical presence, offering flexibility and reduced travel costs. Choosing between on-site and remote inspection depends on factors such as inspection complexity, site accessibility, and the need for immediate interaction with the environment.

Table of Comparison

| Criteria | On-site Inspection | Remote Inspection |

|---|---|---|

| Definition | Physical presence at the location to examine the asset or site. | Inspection conducted via digital tools without physical presence. |

| Equipment Used | Direct use of measuring tools, sensors, cameras on-site. | Remote cameras, drones, IoT sensors, video conferencing. |

| Speed | Slower due to travel and setup time. | Faster, immediate access without travel delays. |

| Cost | Higher costs related to travel, accommodation, and time. | Lower costs due to reduced travel and resource use. |

| Accuracy | High accuracy with direct observation and hands-on analysis. | Variable accuracy dependent on technology and connectivity. |

| Accessibility | Limited to accessible locations. | Accessible to remote or hazardous locations. |

| Safety | Potential exposure to on-site hazards. | Improved safety by avoiding hazardous environments. |

| Documentation | Manual recording and photography on-site. | Digital recording and real-time data transmission. |

| Use Cases | Infrastructure, manufacturing quality audits, complex repairs. | Routine monitoring, preliminary assessments, inaccessible areas. |

Introduction to Car Type Inspection Methods

Car type inspection methods include on-site inspection, which involves physical examination by inspectors at the vehicle's location, ensuring accurate assessment of exterior, interior, and mechanical components. Remote inspection utilizes digital tools such as high-resolution images and video calls to evaluate car conditions without physical presence, offering efficiency and reduced operational costs. Choosing the appropriate method depends on factors like inspection purpose, accessibility, and the need for detailed, hands-on evaluation.

What is On-site Inspection?

On-site inspection involves a physical visit to the location or facility to assess conditions, verify compliance, and evaluate equipment or processes directly. This method allows inspectors to observe environmental factors, infrastructure, and operational practices in real-time, ensuring accurate data collection. On-site inspections play a critical role in industries such as manufacturing, construction, and regulatory compliance where precise and immediate evaluations are essential.

What is Remote Inspection?

Remote inspection refers to the process of evaluating equipment, facilities, or processes using digital technologies such as cameras, sensors, and live video streaming instead of physical presence. This method enables inspectors to assess compliance, identify defects, and monitor operations from distant locations, reducing travel costs and downtime. Advanced tools like drones, augmented reality, and artificial intelligence enhance the accuracy and efficiency of remote inspections across various industries.

Key Differences: On-site vs Remote Inspection

On-site inspections involve physical presence at the location, allowing inspectors to directly observe conditions and conduct hands-on evaluations, which is crucial for assessing complex or sensitive environments. Remote inspections utilize digital tools such as video conferencing, drones, or IoT sensors to collect data and monitor sites from a distance, offering greater flexibility and efficiency in accessing hard-to-reach areas. Key differences include the immediacy of data verification, with on-site inspections providing real-time tactile feedback, while remote inspections rely on the quality and reliability of transmitted information.

Accuracy and Reliability Comparison

On-site inspections offer higher accuracy and reliability due to direct physical access, allowing inspectors to identify subtle defects and environmental factors that remote methods may overlook. Remote inspections rely heavily on digital tools and video technology, which can limit detail resolution and lead to potential misinterpretations, affecting overall reliability. Comparing both, on-site inspections remain the gold standard for critical assessments, while remote inspections provide efficient, less accurate alternatives suitable for preliminary evaluations.

Cost Analysis: On-site vs Remote Inspection

On-site inspection incurs higher costs due to travel, accommodation, and extended manpower hours, significantly impacting budgets for large-scale projects or multiple site visits. Remote inspection reduces expenses by utilizing digital tools and real-time communication, minimizing logistical expenditures and enabling faster turnaround times. Cost analysis reveals remote inspections offer substantial savings in operational costs while maintaining inspection quality through advanced technologies such as high-resolution cameras and IoT sensors.

Convenience and Accessibility Factors

On-site inspection provides direct access to physical assets, enabling inspectors to perform detailed evaluations and gather real-time data, which is essential for complex or high-risk environments. Remote inspection leverages digital tools and technologies, allowing for flexible scheduling and reducing travel time and costs, thereby enhancing convenience and accessibility for geographically dispersed sites. Both methods optimize inspection workflows, but remote inspections significantly increase reach and efficiency in routine or low-risk assessments.

Technological Requirements for Remote Inspection

Remote inspection demands advanced technological infrastructure, including high-resolution cameras, reliable internet connectivity, and secure cloud platforms to facilitate real-time data transmission and communication. Integration of IoT sensors and augmented reality tools enhances the accuracy and efficiency of remote assessments by providing detailed visual and operational insights. Compliance with cybersecurity protocols and data encryption standards ensures the integrity and confidentiality of inspection data during remote operations.

Applications Best Suited for Each Method

On-site inspection is best suited for applications requiring physical access to equipment, machinery, or infrastructure to identify wear, damage, or compliance with safety standards. Remote inspection excels in monitoring large-scale or hazardous environments, using drones, sensors, or video feeds to gather data without the need for physical presence. Industries like manufacturing, oil and gas, and utilities leverage on-site inspections for detailed assessments, while construction, agriculture, and wind energy benefit from remote inspection for real-time, cost-effective, and safer evaluations.

Choosing the Right Inspection Type for Your Vehicle

On-site inspection provides a comprehensive, hands-on vehicle assessment by experienced inspectors, ensuring accurate detection of physical damages and mechanical issues. Remote inspection leverages high-resolution video and digital tools to offer convenience and faster turnaround, ideal for preliminary evaluations or when location constraints exist. Selecting the right inspection type depends on the vehicle's condition, inspection purpose, and the level of detail required, balancing convenience with thoroughness for optimal results.

On-site inspection vs remote inspection Infographic

cardiffo.com

cardiffo.com