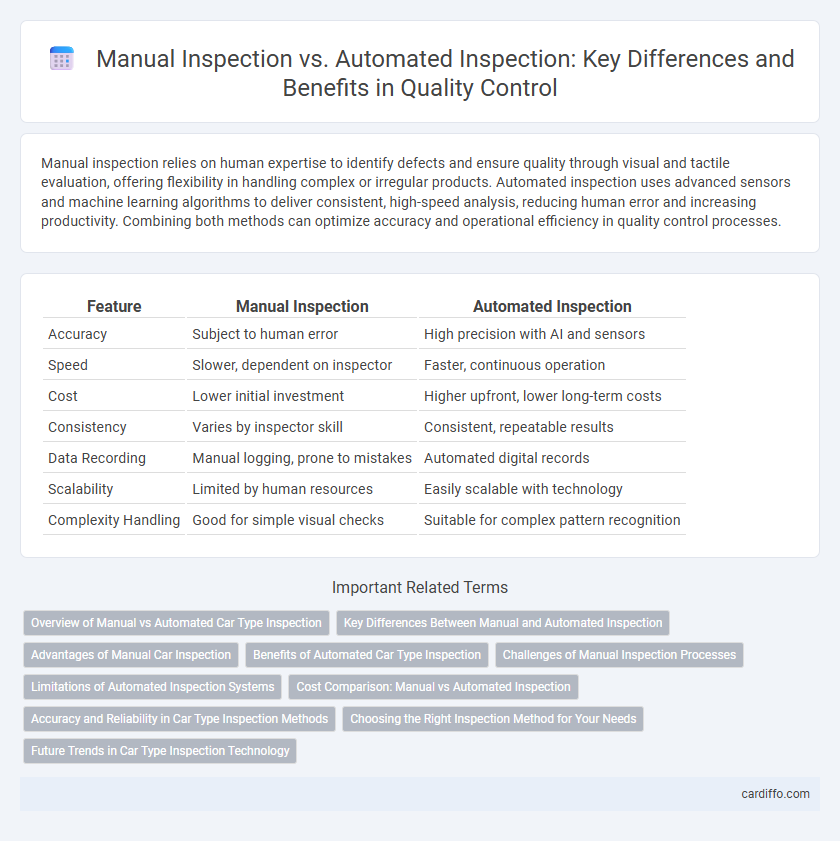

Manual inspection relies on human expertise to identify defects and ensure quality through visual and tactile evaluation, offering flexibility in handling complex or irregular products. Automated inspection uses advanced sensors and machine learning algorithms to deliver consistent, high-speed analysis, reducing human error and increasing productivity. Combining both methods can optimize accuracy and operational efficiency in quality control processes.

Table of Comparison

| Feature | Manual Inspection | Automated Inspection |

|---|---|---|

| Accuracy | Subject to human error | High precision with AI and sensors |

| Speed | Slower, dependent on inspector | Faster, continuous operation |

| Cost | Lower initial investment | Higher upfront, lower long-term costs |

| Consistency | Varies by inspector skill | Consistent, repeatable results |

| Data Recording | Manual logging, prone to mistakes | Automated digital records |

| Scalability | Limited by human resources | Easily scalable with technology |

| Complexity Handling | Good for simple visual checks | Suitable for complex pattern recognition |

Overview of Manual vs Automated Car Type Inspection

Manual car type inspection relies on trained inspectors to visually examine vehicles for defects, ensuring detailed, context-aware assessments but often resulting in longer inspection times and potential human error. Automated car type inspection employs advanced sensors, cameras, and AI-driven algorithms to quickly identify car models and detect anomalies with high accuracy and consistency. Combining both methods enhances accuracy and efficiency, with automation handling repetitive tasks and manual inspection providing nuanced judgment in complex cases.

Key Differences Between Manual and Automated Inspection

Manual inspection relies on human sensory skills and judgment to identify defects, allowing for adaptability in complex or variable environments but often resulting in slower processing times and inconsistent accuracy. Automated inspection utilizes advanced technologies such as machine vision, artificial intelligence, and robotics to perform fast, precise, and repeatable quality assessments, enhancing efficiency and reducing human error. Key differences include consistency of results, inspection speed, scalability, and the ability to handle high-volume production with minimal downtime.

Advantages of Manual Car Inspection

Manual car inspection offers the advantage of keen human judgment capable of detecting subtle anomalies that automated systems might overlook. Experienced inspectors can adapt to unique vehicle conditions, providing a thorough assessment beyond algorithmic limitations. This hands-on approach ensures personalized evaluation, enhancing the detection of wear, corrosion, and irregularities in car components.

Benefits of Automated Car Type Inspection

Automated car type inspection enhances accuracy by utilizing advanced image recognition and machine learning algorithms, significantly reducing human error. This technology accelerates inspection speed, enabling real-time data processing and higher throughput in vehicle audits. The system also improves consistency and traceability, offering detailed digital records that support compliance and quality control.

Challenges of Manual Inspection Processes

Manual inspection processes face challenges such as human error, inconsistency, and fatigue, leading to decreased accuracy and reliability. The subjective nature of manual assessments can result in variability across inspectors and inspection cycles. Moreover, manual inspections are often time-consuming and labor-intensive, limiting throughput and scalability in quality control operations.

Limitations of Automated Inspection Systems

Automated inspection systems often face challenges with detecting subtle defects that require human judgment or contextual understanding, limiting their effectiveness in complex quality control scenarios. These systems typically struggle with variations in product appearance, lighting conditions, and unexpected anomalies, leading to false positives or missed defects. Dependence on high-quality training data and initial programming further restricts their adaptability to new or evolving inspection tasks.

Cost Comparison: Manual vs Automated Inspection

Manual inspection incurs higher labor costs due to the need for skilled personnel to perform repetitive tasks, leading to increased operational expenses over time. Automated inspection systems require a significant initial investment but reduce ongoing labor costs and minimize human error, resulting in lower long-term expenses. Cost analysis reveals that automated inspection provides greater return on investment for high-volume production environments by maximizing efficiency and consistency.

Accuracy and Reliability in Car Type Inspection Methods

Manual inspection in car type methods relies heavily on human expertise, which can introduce variability and potential errors, affecting accuracy and reliability. Automated inspection utilizes advanced sensors and machine learning algorithms to deliver consistent, precise evaluations, significantly enhancing detection of defects in vehicle components. Combining sensor data with AI-driven analysis improves inspection repeatability and reduces oversight compared to manual methods.

Choosing the Right Inspection Method for Your Needs

Selecting the appropriate inspection method depends on factors such as product complexity, inspection accuracy requirements, and production volume. Manual inspection offers flexibility and human judgment for intricate or low-volume tasks, while automated inspection provides higher speed, consistency, and data traceability for large-scale operations. Balancing cost, efficiency, and quality standards ensures optimal inspection outcomes tailored to specific industrial needs.

Future Trends in Car Type Inspection Technology

Future trends in car type inspection technology indicate a significant shift toward automated inspection systems powered by artificial intelligence and machine learning, enhancing accuracy and speed compared to manual inspection methods. Integration of advanced sensors, computer vision, and IoT devices in automated inspections enables real-time data collection and predictive maintenance, reducing downtime and improving vehicle safety. The automotive industry's increasing adoption of automated inspection technologies supports scalability, consistency, and comprehensive analysis, positioning these systems as essential for next-generation vehicle quality control.

Manual Inspection vs Automated Inspection Infographic

cardiffo.com

cardiffo.com