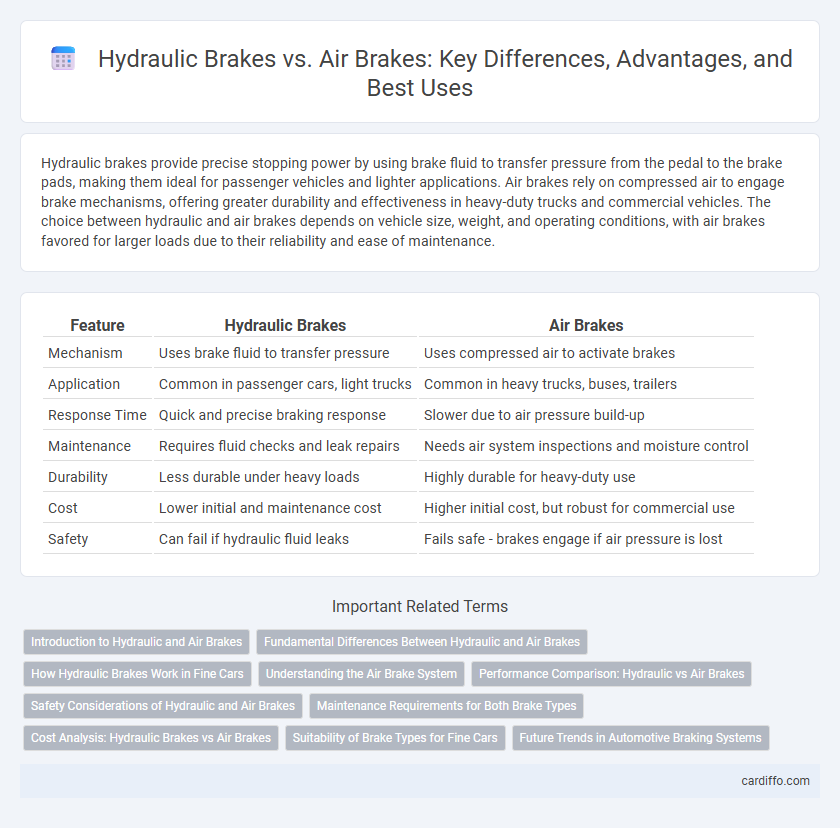

Hydraulic brakes provide precise stopping power by using brake fluid to transfer pressure from the pedal to the brake pads, making them ideal for passenger vehicles and lighter applications. Air brakes rely on compressed air to engage brake mechanisms, offering greater durability and effectiveness in heavy-duty trucks and commercial vehicles. The choice between hydraulic and air brakes depends on vehicle size, weight, and operating conditions, with air brakes favored for larger loads due to their reliability and ease of maintenance.

Table of Comparison

| Feature | Hydraulic Brakes | Air Brakes |

|---|---|---|

| Mechanism | Uses brake fluid to transfer pressure | Uses compressed air to activate brakes |

| Application | Common in passenger cars, light trucks | Common in heavy trucks, buses, trailers |

| Response Time | Quick and precise braking response | Slower due to air pressure build-up |

| Maintenance | Requires fluid checks and leak repairs | Needs air system inspections and moisture control |

| Durability | Less durable under heavy loads | Highly durable for heavy-duty use |

| Cost | Lower initial and maintenance cost | Higher initial cost, but robust for commercial use |

| Safety | Can fail if hydraulic fluid leaks | Fails safe - brakes engage if air pressure is lost |

Introduction to Hydraulic and Air Brakes

Hydraulic brakes utilize fluid pressure to transfer force from the brake pedal to the brake mechanism, offering precise control and smooth braking performance commonly found in passenger vehicles. Air brakes operate by using compressed air to activate brake chambers, delivering powerful stopping force suited for heavy-duty trucks and buses due to their reliability and ease of maintenance. Understanding the fundamental differences between hydraulic and air brake systems is essential for selecting the appropriate braking technology based on vehicle size, weight, and operational requirements.

Fundamental Differences Between Hydraulic and Air Brakes

Hydraulic brakes utilize fluid pressure transmitted through brake lines to activate brake pads, offering precise stopping power and quicker response times, typically found in passenger vehicles. Air brakes operate using compressed air to apply force to brake components, designed for heavy-duty vehicles like trucks and buses, providing greater braking force over longer distances. The fundamental difference lies in the medium used for force transmission--liquid in hydraulic systems versus compressed air in pneumatic systems--impacting maintenance requirements, system complexity, and application suitability.

How Hydraulic Brakes Work in Fine Cars

Hydraulic brakes in fine cars use brake fluid to transfer force from the brake pedal to the brake pads, creating friction that slows the vehicle. The system relies on a master cylinder that generates hydraulic pressure, which is evenly distributed through brake lines to each wheel's caliper. Precision engineering in fine cars ensures optimal brake responsiveness and smooth stopping power under various driving conditions.

Understanding the Air Brake System

The air brake system operates by using compressed air to exert pressure on brake shoes, creating friction to slow or stop a vehicle. Key components include the air compressor, reservoir tanks, brake chambers, and slack adjusters, all working together to ensure reliable braking performance in heavy-duty trucks and buses. Proper maintenance of air lines, valves, and moisture traps is essential to prevent air leaks and ensure consistent brake response.

Performance Comparison: Hydraulic vs Air Brakes

Hydraulic brakes deliver superior stopping power through fluid pressure, ensuring smooth and precise braking response ideal for light to medium vehicles, while air brakes rely on compressed air systems that provide consistent force for heavy-duty trucks and buses. Hydraulic systems offer faster pedal response and better modulation, but air brakes excel in durability and safety by preventing brake failure through redundant air reservoirs. Performance efficiency in different vehicle types determines the optimal braking choice, with hydraulic brakes favored for lighter loads and air brakes preferred for high-load, commercial applications.

Safety Considerations of Hydraulic and Air Brakes

Hydraulic brakes provide precise stopping power with minimal lag, making them highly reliable for passenger vehicles where quick response is critical for safety. Air brakes offer superior performance for heavy-duty trucks by maintaining braking force through compressed air systems, reducing the risk of brake failure under high loads. Both systems require regular maintenance to ensure safety, with hydraulic brakes sensitive to fluid leaks and air brakes dependent on maintaining adequate air pressure.

Maintenance Requirements for Both Brake Types

Hydraulic brakes require regular inspection of fluid levels, brake pads, and calipers to prevent leaks and maintain optimal pressure, with periodic fluid replacement essential to avoid moisture contamination. Air brakes demand thorough checks of air compressor function, air lines, and tanks to prevent pressure loss, along with routine draining of moisture and contaminants from air tanks to ensure reliable brake response. Both systems benefit from scheduled maintenance, but air brakes generally require more frequent inspections due to the complexity of their pneumatic components.

Cost Analysis: Hydraulic Brakes vs Air Brakes

Hydraulic brakes typically incur lower initial costs and simpler maintenance compared to air brakes, making them cost-effective for light to medium vehicles. Air brakes, while more expensive upfront, offer greater durability and reduced long-term maintenance expenses, especially suitable for heavy-duty trucks and commercial vehicles. Evaluating total ownership costs, including installation, repair, and lifespan, is crucial for determining the most economical braking system for specific vehicle applications.

Suitability of Brake Types for Fine Cars

Hydraulic brakes are often preferred for fine cars due to their superior responsiveness and smoother braking performance, which provides precise control and enhanced safety. Air brakes, while robust and effective for heavy-duty vehicles, are typically less suited for fine cars because of their bulkier system and slower reaction time. The compact, low-maintenance nature of hydraulic brake systems makes them ideal for high-performance, luxury, and smaller passenger vehicles.

Future Trends in Automotive Braking Systems

Hydraulic brakes continue to evolve with advancements in electronic brake-force distribution and integration with autonomous driving systems, enhancing precision and safety. Air brakes, predominantly used in heavy-duty vehicles, are seeing innovations in lightweight materials and energy-efficient compressors to improve performance and reduce emissions. Future automotive braking systems will increasingly combine hydraulic and air technologies with smart sensors and AI for adaptive braking, ensuring optimized response across diverse driving conditions.

Hydraulic Brakes vs Air Brakes Infographic

cardiffo.com

cardiffo.com