SCR systems reduce NOx emissions by injecting ammonia into the exhaust stream, converting pollutants into nitrogen and water through a catalytic reaction. LNT systems trap NOx on a catalyst during lean operation and periodically regenerate by rich combustion, releasing harmless nitrogen gases. SCR generally offers higher NOx reduction efficiency and better fuel economy compared to LNT, making it preferable for heavy-duty diesel engines.

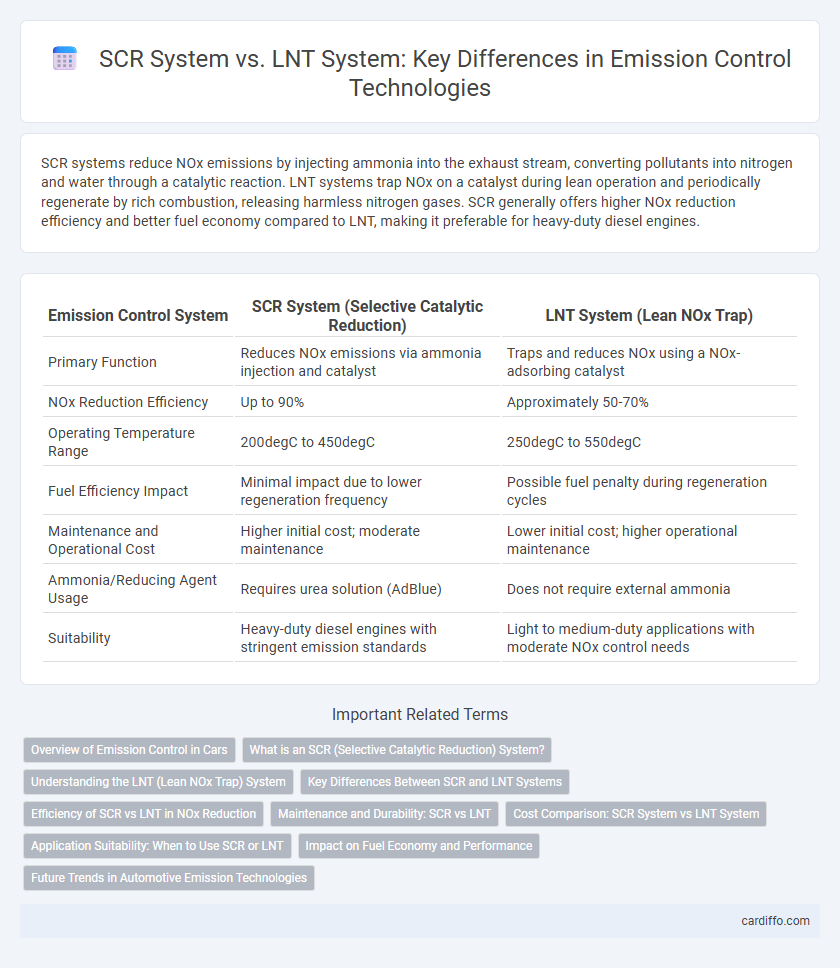

Table of Comparison

| Emission Control System | SCR System (Selective Catalytic Reduction) | LNT System (Lean NOx Trap) |

|---|---|---|

| Primary Function | Reduces NOx emissions via ammonia injection and catalyst | Traps and reduces NOx using a NOx-adsorbing catalyst |

| NOx Reduction Efficiency | Up to 90% | Approximately 50-70% |

| Operating Temperature Range | 200degC to 450degC | 250degC to 550degC |

| Fuel Efficiency Impact | Minimal impact due to lower regeneration frequency | Possible fuel penalty during regeneration cycles |

| Maintenance and Operational Cost | Higher initial cost; moderate maintenance | Lower initial cost; higher operational maintenance |

| Ammonia/Reducing Agent Usage | Requires urea solution (AdBlue) | Does not require external ammonia |

| Suitability | Heavy-duty diesel engines with stringent emission standards | Light to medium-duty applications with moderate NOx control needs |

Overview of Emission Control in Cars

Selective Catalytic Reduction (SCR) systems reduce nitrogen oxide (NOx) emissions by injecting a urea-based solution into the exhaust stream, converting NOx into nitrogen and water, making them highly effective for heavy-duty diesel engines. Lean NOx Traps (LNT), or NOx adsorbers, store NOx under lean conditions and periodically regenerate by reducing NOx to nitrogen during rich conditions, offering a compact solution for light-duty vehicles. Both technologies are critical for meeting stringent Euro 6 and EPA Tier 3 emission standards, with SCR favored for superior NOx reduction efficiency and LNT valued for integration in smaller engine platforms.

What is an SCR (Selective Catalytic Reduction) System?

An SCR (Selective Catalytic Reduction) System is an advanced emission control technology designed to reduce nitrogen oxide (NOx) emissions from diesel engines by injecting a urea-based solution, commonly known as Diesel Exhaust Fluid (DEF), into the exhaust stream. This chemical reaction converts harmful NOx gases into harmless nitrogen and water vapor, significantly lowering environmental pollution and complying with stringent emission standards. SCR systems are widely used in heavy-duty vehicles, industrial machinery, and power plants to achieve high NOx reduction efficiency compared to other technologies like Lean NOx Traps (LNT).

Understanding the LNT (Lean NOx Trap) System

The Lean NOx Trap (LNT) system reduces nitrogen oxides (NOx) emissions by adsorbing NOx onto a catalyst during lean engine operation and periodically regenerating through rich fuel pulses to convert stored NOx into harmless nitrogen. Unlike the Selective Catalytic Reduction (SCR) system, which uses urea-based reductants to convert NOx in the exhaust, LNT operates without additional chemicals, making it simpler but often less efficient in high-load conditions. LNT systems excel in low-to-moderate temperature ranges, providing effective NOx reduction in gasoline and lean-burn diesel engines.

Key Differences Between SCR and LNT Systems

SCR (Selective Catalytic Reduction) systems use ammonia or urea to convert nitrogen oxides (NOx) into nitrogen and water vapor, achieving high NOx reduction efficiency typically above 90%. LNT (Lean NOx Trap) systems store NOx on a catalyst surface during lean engine operation and periodically regenerate by reducing the stored NOx, generally providing lower reduction efficiency around 50-70%. SCR systems require a separate reductant dosing system and are more complex, whereas LNT systems are simpler but less effective in stringent emission standards compliance.

Efficiency of SCR vs LNT in NOx Reduction

Selective Catalytic Reduction (SCR) systems achieve higher NOx reduction efficiency, often exceeding 90%, by injecting ammonia or urea to convert nitrogen oxides into harmless nitrogen and water. Lean NOx Trap (LNT) systems typically reach 50-70% NOx reduction by adsorbing and periodically regenerating NOx on a catalyst but suffer efficiency losses at low temperatures. SCR remains the preferred technology for heavy-duty diesel engines due to its superior performance across diverse operating conditions and lower ammonia slip risk.

Maintenance and Durability: SCR vs LNT

SCR (Selective Catalytic Reduction) systems generally require less frequent maintenance than LNT (Lean NOx Trap) systems due to their more robust catalysts and simpler regeneration process. The durability of SCR catalysts is typically higher, maintaining efficiency over longer operational hours without significant degradation. In contrast, LNT systems experience faster catalyst aging and require more frequent regeneration cycles, leading to increased maintenance costs and reduced long-term durability.

Cost Comparison: SCR System vs LNT System

Selective Catalytic Reduction (SCR) systems generally have higher upfront costs compared to Lean NOx Trap (LNT) systems due to the complexity of their catalysts and dosing equipment. However, SCR offers greater fuel efficiency and lower operating costs over time, potentially offsetting initial expenses with improved NOx reduction and lower urea consumption. LNT systems tend to be less expensive initially but may incur higher maintenance and fuel penalties, making SCR a more cost-effective solution for stringent emission regulations in the long run.

Application Suitability: When to Use SCR or LNT

Selective Catalytic Reduction (SCR) systems excel in heavy-duty diesel engines with high nitrogen oxide (NOx) emissions, typically used in trucks, buses, and industrial machinery due to their superior NOx reduction efficiency and compatibility with urea-based reductants. Lean NOx Trap (LNT) systems suit light-duty vehicles and smaller engines where space constraints and cost sensitivity favor compact designs, offering effective NOx control during low-temperature operations. SCR is optimal for continuous high-load applications, while LNT is preferable for urban driving cycles with frequent cold starts and variable engine loads.

Impact on Fuel Economy and Performance

Selective Catalytic Reduction (SCR) systems improve fuel economy by enabling engines to run at higher combustion temperatures, thereby enhancing performance and reducing nitrogen oxide (NOx) emissions more efficiently than Lean NOx Trap (LNT) systems. LNT systems often degrade fuel economy due to periodic rich-burn cycles needed to regenerate the trap, which increases fuel consumption and reduces engine efficiency. SCR systems maintain consistent engine performance while offering superior NOx reduction, making them favorable in modern emissions control strategies.

Future Trends in Automotive Emission Technologies

Selective Catalytic Reduction (SCR) systems dominate future automotive emission controls due to their superior efficiency in reducing nitrogen oxides (NOx) from diesel engines through ammonia injection. Lean NOx Trap (LNT) systems are evolving to complement SCR by targeting low-temperature NOx reduction and improving catalyst durability under diverse driving conditions. Advancements in hybrid SCR-LNT integration and real-time emission monitoring are critical trends driving stricter regulatory compliance and lower environmental impact in next-generation vehicles.

SCR System vs LNT System Infographic

cardiffo.com

cardiffo.com