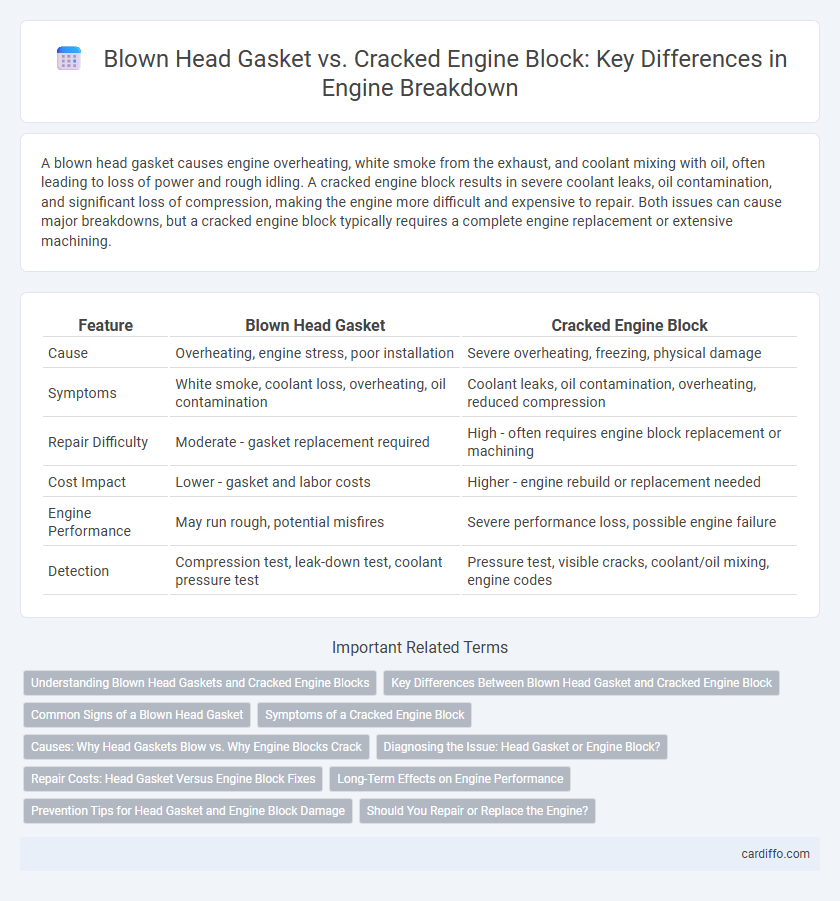

A blown head gasket causes engine overheating, white smoke from the exhaust, and coolant mixing with oil, often leading to loss of power and rough idling. A cracked engine block results in severe coolant leaks, oil contamination, and significant loss of compression, making the engine more difficult and expensive to repair. Both issues can cause major breakdowns, but a cracked engine block typically requires a complete engine replacement or extensive machining.

Table of Comparison

| Feature | Blown Head Gasket | Cracked Engine Block |

|---|---|---|

| Cause | Overheating, engine stress, poor installation | Severe overheating, freezing, physical damage |

| Symptoms | White smoke, coolant loss, overheating, oil contamination | Coolant leaks, oil contamination, overheating, reduced compression |

| Repair Difficulty | Moderate - gasket replacement required | High - often requires engine block replacement or machining |

| Cost Impact | Lower - gasket and labor costs | Higher - engine rebuild or replacement needed |

| Engine Performance | May run rough, potential misfires | Severe performance loss, possible engine failure |

| Detection | Compression test, leak-down test, coolant pressure test | Pressure test, visible cracks, coolant/oil mixing, engine codes |

Understanding Blown Head Gaskets and Cracked Engine Blocks

A blown head gasket occurs when the seal between the engine block and cylinder head fails, leading to coolant leakage and engine overheating, often indicated by white smoke from the exhaust and milky oil. A cracked engine block involves a fracture in the metal structure of the engine itself, causing severe coolant loss, poor compression, and possible engine failure. Diagnosing these issues requires pressure tests and visual inspections, as both can cause similar symptoms but demand different repairs.

Key Differences Between Blown Head Gasket and Cracked Engine Block

A blown head gasket typically results in coolant leakage, engine overheating, and white exhaust smoke, while a cracked engine block causes severe coolant loss, oil contamination, and significant pressure drop in the combustion chamber. Diagnostic tests such as a compression test or a leak-down test help differentiate between the two by measuring pressure loss and identifying combustion gases in the coolant. Repair costs and complexity also vary, with blown head gaskets generally being more economical and less labor-intensive to fix compared to the extensive repairs or replacement required for cracked engine blocks.

Common Signs of a Blown Head Gasket

Common signs of a blown head gasket include white smoke emitting from the exhaust, engine overheating, and milky oil indicating coolant contamination. Loss of engine power and rough idling may also signal gasket failure, distinguishing it from a cracked engine block which often causes external coolant leaks. Early detection requires monitoring coolant levels and checking for bubbles in the radiator or coolant reservoir during engine operation.

Symptoms of a Cracked Engine Block

Symptoms of a cracked engine block include coolant leakage under the vehicle, white smoke from the exhaust indicating coolant burning, and overheating due to loss of coolant or compromised engine integrity. Engine misfires, rough idling, and a noticeable drop in engine performance can also signal internal cracks affecting combustion chambers or coolant passages. Checking for a milky discoloration in the engine oil confirms coolant contamination, a common result of a cracked block.

Causes: Why Head Gaskets Blow vs. Why Engine Blocks Crack

Head gaskets blow primarily due to overheating, excessive pressure, or poor installation, which compromise the seal between the engine block and cylinder head. Cracked engine blocks typically result from severe thermal stress, freezing temperatures causing coolant expansion, or manufacturing defects leading to structural weaknesses. Understanding these distinct causes helps diagnose engine failures accurately and implement appropriate repairs.

Diagnosing the Issue: Head Gasket or Engine Block?

Diagnosing whether a blown head gasket or a cracked engine block is causing your vehicle's breakdown requires careful inspection of symptoms such as engine overheating, coolant loss, and white smoke from the exhaust. Performing a compression test and a leak-down test can help identify head gasket failure, while pressure testing the cooling system and inspecting for visible cracks often indicate a damaged engine block. Using specialized diagnostic tools like a block tester with chemical detection can accurately distinguish between the combustion gases leaking into the coolant, confirming the source of the breakdown.

Repair Costs: Head Gasket Versus Engine Block Fixes

Repair costs for a blown head gasket typically range between $1,000 and $2,000, depending on labor rates and parts needed, while fixing a cracked engine block often exceeds $2,500 due to the complexity and potential need for engine replacement or machining. A head gasket repair involves disassembling the engine's top end to replace the gasket, whereas a cracked engine block repair may require welding, replacement, or complete engine replacement, significantly increasing costs. Insurance coverage and the vehicle's make, model, and age also heavily influence the final repair expense.

Long-Term Effects on Engine Performance

A blown head gasket leads to coolant and oil mixing, causing overheating and reduced engine compression, which significantly diminishes long-term performance and can result in engine failure if untreated. A cracked engine block, however, often causes severe coolant leaks and structural damage, leading to catastrophic engine failure and requiring complete engine replacement. Both issues drastically affect engine reliability, but a cracked block typically presents more irreversible long-term damage than a blown head gasket.

Prevention Tips for Head Gasket and Engine Block Damage

Regular maintenance such as timely coolant flushes and using high-quality engine oil significantly reduce the risk of blown head gaskets and cracked engine blocks. Monitoring engine temperature and avoiding overheating prevents thermal stress that often leads to gasket failure and block cracks. Inspecting for leaks and ensuring proper torque on cylinder head bolts help maintain engine integrity and extend component lifespan.

Should You Repair or Replace the Engine?

A blown head gasket often allows for repairs by replacing seals and gaskets, which can restore engine function at a lower cost compared to a cracked engine block, where structural damage typically necessitates engine replacement. Repairing a cracked engine block risks recurring leaks and further damage due to compromised metal integrity, making replacement the more reliable long-term solution despite higher initial expenses. Evaluating the vehicle's overall condition, repair costs, and engine value helps determine whether to invest in a gasket repair or commit to a full engine replacement.

Blown head gasket vs cracked engine block Infographic

cardiffo.com

cardiffo.com