Fuel pump failure causes a complete loss of fuel delivery, resulting in engine stalling or inability to start, while injector clog leads to uneven fuel spray, causing misfires and reduced engine performance. Diagnosing fuel pump issues involves checking fuel pressure, whereas injector problems require cleaning or replacement to restore proper fuel atomization. Understanding these differences helps target repairs effectively and prevents prolonged engine damage.

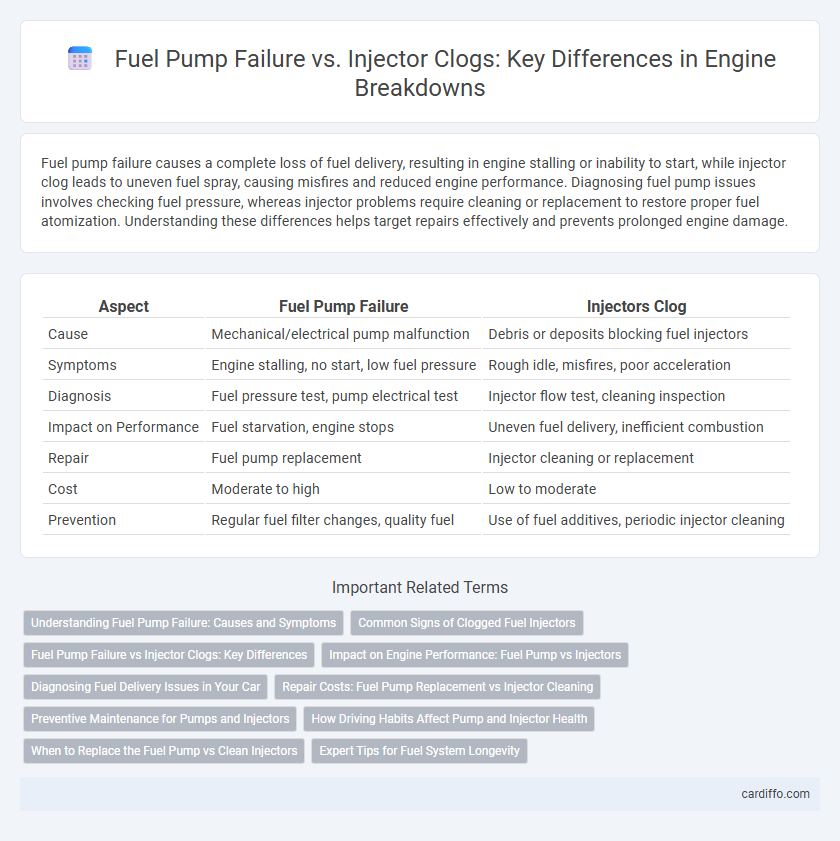

Table of Comparison

| Aspect | Fuel Pump Failure | Injectors Clog |

|---|---|---|

| Cause | Mechanical/electrical pump malfunction | Debris or deposits blocking fuel injectors |

| Symptoms | Engine stalling, no start, low fuel pressure | Rough idle, misfires, poor acceleration |

| Diagnosis | Fuel pressure test, pump electrical test | Injector flow test, cleaning inspection |

| Impact on Performance | Fuel starvation, engine stops | Uneven fuel delivery, inefficient combustion |

| Repair | Fuel pump replacement | Injector cleaning or replacement |

| Cost | Moderate to high | Low to moderate |

| Prevention | Regular fuel filter changes, quality fuel | Use of fuel additives, periodic injector cleaning |

Understanding Fuel Pump Failure: Causes and Symptoms

Fuel pump failure occurs when the pump cannot deliver sufficient fuel pressure to the engine, often caused by electrical issues, clogged fuel filters, or mechanical wear. Symptoms include engine sputtering at high speeds, difficulty starting, and sudden power loss during acceleration. Diagnosing fuel pump failure requires checking fuel pressure levels, inspecting the pump relay, and listening for unusual noises from the fuel tank area.

Common Signs of Clogged Fuel Injectors

Common signs of clogged fuel injectors include engine misfires, rough idling, and reduced fuel efficiency. Drivers may also notice increased exhaust emissions and difficulty starting the vehicle. These symptoms often result from disrupted fuel spray patterns, causing uneven combustion and decreased engine performance.

Fuel Pump Failure vs Injector Clogs: Key Differences

Fuel pump failure typically results in inadequate fuel pressure, causing engine stalling, difficulty starting, and loss of power, whereas injector clogs lead to uneven fuel distribution, rough idling, and misfires. Fuel pumps are mechanical or electric components responsible for delivering fuel from the tank to the engine, making their failure more critical for engine operation. Injector clogs often accumulate carbon deposits or debris, reducing fuel atomization efficiency and leading to poor combustion performance.

Impact on Engine Performance: Fuel Pump vs Injectors

Fuel pump failure causes a significant drop in fuel pressure, leading to engine misfires, stalling, and complete engine shutdown due to insufficient fuel delivery. Injector clogging reduces fuel atomization and distribution, causing rough idling, decreased power, and increased emissions but typically allows the engine to run at reduced efficiency. Both issues degrade engine performance, but fuel pump failure generally results in more severe operational disruption.

Diagnosing Fuel Delivery Issues in Your Car

Diagnosing fuel delivery issues involves distinguishing between fuel pump failure and injector clogging by analyzing symptoms such as engine sputtering, stalling, or rough idling. Fuel pump failure often results in no fuel pressure, detected through a fuel pressure gauge reading below manufacturer specifications, while injector clogging typically leads to uneven fuel spray patterns visible during injector testing or cleaning procedures. Accurate diagnosis can prevent unnecessary part replacements and ensure efficient engine performance.

Repair Costs: Fuel Pump Replacement vs Injector Cleaning

Fuel pump replacement typically costs between $400 and $800, including parts and labor, while injector cleaning ranges from $50 to $150, depending on the method used and the vehicle model. Fuel pump failure often requires more extensive labor and higher-priced parts, making it a more expensive repair compared to injector cleaning, which is generally quicker and less invasive. Repair costs can vary significantly based on vehicle type, location, and the severity of the issue, emphasizing the importance of accurate diagnosis.

Preventive Maintenance for Pumps and Injectors

Fuel pump failure often results from wear and tear, requiring regular inspection and timely replacement to ensure optimal performance. Injector clogging can be prevented by using high-quality fuel and frequent cleaning with specialized additives designed to dissolve deposits. Implementing a preventive maintenance schedule that includes monitoring fuel filter condition and conducting injector flow tests helps avoid costly breakdowns and maintains engine efficiency.

How Driving Habits Affect Pump and Injector Health

Frequent short trips and excessive idling increase the risk of fuel pump failure by preventing proper fuel circulation and cooling, leading to overheating and wear. Poor driving habits, such as using low-quality fuel or ignoring regular maintenance, contribute to injector clog by allowing dirt and deposits to accumulate in the fuel system. Maintaining steady speeds and using high-quality fuel improves fuel pump efficiency and injector cleanliness, extending the lifespan of both components.

When to Replace the Fuel Pump vs Clean Injectors

Fuel pump failure typically requires immediate replacement when symptoms like engine sputtering, loss of power, or no-start conditions occur due to insufficient fuel pressure. Injector clog presents as rough idling, misfires, or reduced fuel efficiency and can often be resolved by professional cleaning or fuel additive treatments. Replacing the fuel pump is critical when diagnostics confirm pump malfunction, while injector cleaning is advisable when fuel delivery issues stem from dirt or deposits obstructing injector spray patterns.

Expert Tips for Fuel System Longevity

Fuel pump failure often results from consistent overheating and contaminated fuel, which places undue stress on the pump motor. Clogged injectors typically arise due to poor fuel quality and accumulate deposits, leading to decreased engine performance and fuel efficiency. Expert tips for fuel system longevity emphasize regular use of high-quality fuel, timely replacement of fuel filters, and periodic professional cleaning of injectors to ensure optimal fuel pressure and consistent spray patterns.

Fuel pump failure vs injectors clog Infographic

cardiffo.com

cardiffo.com