Spiral cells offer higher surface area within a compact design, resulting in improved energy density and better heat dissipation compared to flat plate batteries. Flat plate cells are known for easier manufacturing and lower cost, but they often experience reduced efficiency and shorter lifespan due to uneven wear and thermal stress. Choosing between spiral cell and flat plate battery designs depends on the balance of performance, durability, and budget requirements for the specific application.

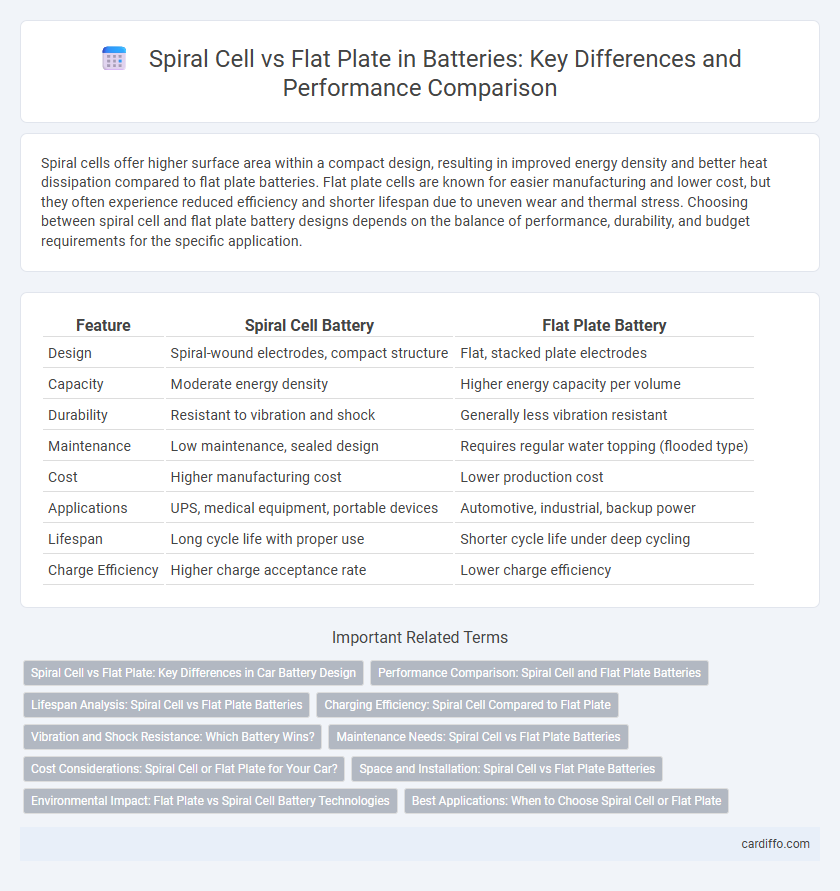

Table of Comparison

| Feature | Spiral Cell Battery | Flat Plate Battery |

|---|---|---|

| Design | Spiral-wound electrodes, compact structure | Flat, stacked plate electrodes |

| Capacity | Moderate energy density | Higher energy capacity per volume |

| Durability | Resistant to vibration and shock | Generally less vibration resistant |

| Maintenance | Low maintenance, sealed design | Requires regular water topping (flooded type) |

| Cost | Higher manufacturing cost | Lower production cost |

| Applications | UPS, medical equipment, portable devices | Automotive, industrial, backup power |

| Lifespan | Long cycle life with proper use | Shorter cycle life under deep cycling |

| Charge Efficiency | Higher charge acceptance rate | Lower charge efficiency |

Spiral Cell vs Flat Plate: Key Differences in Car Battery Design

Spiral cell batteries feature tightly wound electrodes in a cylindrical shape, enhancing surface area and promoting efficient heat dissipation, which supports higher power output and faster charging for automotive applications. Flat plate batteries use stacked, flat electrodes that provide a larger active material volume, resulting in higher energy density and longer lifecycle but typically exhibit slower charge rates. The key differences in car battery design involve the trade-offs between spiral cells' rapid energy delivery and flat plates' capacity for sustained energy storage.

Performance Comparison: Spiral Cell and Flat Plate Batteries

Spiral cell batteries offer superior vibration resistance and higher power output due to their tightly wound electrode design, making them ideal for high-drain applications such as power tools and medical devices. Flat plate batteries, characterized by their stacked electrode plates, provide better capacity and longer cycle life, preferred in automotive and backup power systems. Performance comparison shows spiral cells excel in rapid discharge and durability under mechanical stress, while flat plates deliver sustained energy and cost efficiency.

Lifespan Analysis: Spiral Cell vs Flat Plate Batteries

Spiral cell batteries exhibit superior lifespan and consistent performance due to their robust design, which minimizes the risk of electrolyte stratification and sedimentation compared to flat plate batteries. Flat plate batteries, while cost-effective, often experience shorter cycle life and increased maintenance requirements because of their tendency to suffer from plate degradation and reduced active material utilization. Lifespan analysis reveals that spiral cells maintain higher capacity retention over extended charge-discharge cycles, making them ideal for applications demanding reliability and longevity.

Charging Efficiency: Spiral Cell Compared to Flat Plate

Spiral cell batteries exhibit higher charging efficiency compared to flat plate designs due to their increased surface area and improved electrolyte circulation, which reduces internal resistance and heat buildup. This design allows for faster charge acceptance and better performance during high-rate charging cycles. Consequently, spiral cells maintain longer cycle life and more consistent power output under rapid charging conditions.

Vibration and Shock Resistance: Which Battery Wins?

Spiral cell batteries demonstrate superior vibration and shock resistance due to their tightly wound electrode design, which minimizes internal movement and enhances structural integrity. Flat plate batteries, with their stacked electrode plates, are more susceptible to damage from mechanical stress, leading to potential performance degradation under high vibration conditions. In applications demanding robust durability against shocks, spiral cell technology consistently outperforms flat plate batteries, ensuring longer lifespan and reliability.

Maintenance Needs: Spiral Cell vs Flat Plate Batteries

Spiral cell batteries require less maintenance due to their sealed design, which minimizes electrolyte loss and reduces the need for frequent inspections. Flat plate batteries often demand regular water top-ups and cleaning to prevent corrosion and sulfation, increasing maintenance time and costs. The lower maintenance needs of spiral cell batteries make them ideal for applications requiring reliable, hassle-free power sources.

Cost Considerations: Spiral Cell or Flat Plate for Your Car?

Spiral cell batteries generally have higher manufacturing costs due to their complex winding process, making flat plate batteries more economical for bulk production. Flat plate designs offer simpler assembly and lower material expenses, contributing to reduced overall battery costs in automotive applications. When budgeting for car batteries, flat plate options often provide better cost efficiency without significantly compromising performance or lifespan.

Space and Installation: Spiral Cell vs Flat Plate Batteries

Spiral cell batteries offer a compact design that maximizes space efficiency, making them ideal for applications with limited installation areas, such as in medical devices and UPS systems. Flat plate batteries, while typically larger and heavier, provide greater surface area for heat dissipation but require more installation space, often suited for stationary applications like backup power systems. The choice between spiral cell and flat plate batteries depends on balancing spatial constraints with the specific power and thermal management needs of the installation environment.

Environmental Impact: Flat Plate vs Spiral Cell Battery Technologies

Flat plate batteries typically utilize lead-acid chemistry with a straightforward design that allows easier recycling but generate more hazardous waste due to larger amounts of lead and sulfuric acid. Spiral cell batteries often employ nickel-metal hydride (NiMH) or lithium-ion chemistries, resulting in higher energy density and longer life cycles that reduce overall environmental impact despite more complex recycling processes. Lifecycle assessments reveal spiral cells generally offer better sustainability through lower emissions and material consumption compared to conventional flat plate batteries.

Best Applications: When to Choose Spiral Cell or Flat Plate

Spiral cell batteries excel in applications requiring high power density and rapid discharge, making them ideal for automotive starters and uninterruptible power supplies (UPS). Flat plate batteries offer superior deep cycle performance and longer lifespan, suited for renewable energy storage systems and electric vehicles. Selecting between spiral cell and flat plate depends on balancing power delivery needs with cycle durability and maintenance considerations.

Spiral Cell vs Flat Plate Infographic

cardiffo.com

cardiffo.com