SLA (Sealed Lead Acid) and VRLA (Valve-Regulated Lead Acid) batteries are often used interchangeably, but VRLA is a subtype of SLA with enhanced safety features due to its valve regulation system. VRLA batteries minimize gas release and maintenance by recombining gases internally, making them ideal for sealed, spill-proof applications. While both offer reliable power storage, VRLA technology provides improved performance in confined spaces requiring low maintenance and high safety standards.

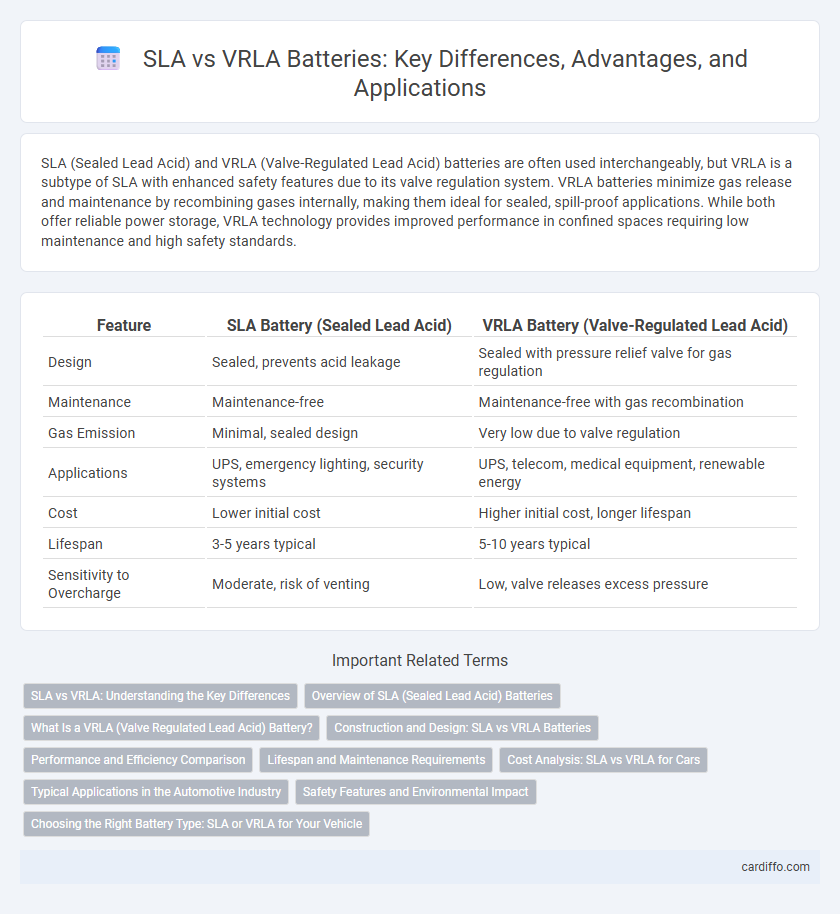

Table of Comparison

| Feature | SLA Battery (Sealed Lead Acid) | VRLA Battery (Valve-Regulated Lead Acid) |

|---|---|---|

| Design | Sealed, prevents acid leakage | Sealed with pressure relief valve for gas regulation |

| Maintenance | Maintenance-free | Maintenance-free with gas recombination |

| Gas Emission | Minimal, sealed design | Very low due to valve regulation |

| Applications | UPS, emergency lighting, security systems | UPS, telecom, medical equipment, renewable energy |

| Cost | Lower initial cost | Higher initial cost, longer lifespan |

| Lifespan | 3-5 years typical | 5-10 years typical |

| Sensitivity to Overcharge | Moderate, risk of venting | Low, valve releases excess pressure |

SLA vs VRLA: Understanding the Key Differences

SLA (Sealed Lead Acid) and VRLA (Valve Regulated Lead Acid) batteries both offer maintenance-free operation, but VRLA is a subset of SLA with enhanced design features such as valve regulation to prevent gas release and leakage. VRLA batteries typically include Absorbent Glass Mat (AGM) or Gel technologies, providing better deep cycle performance, improved safety, and longer service life compared to traditional SLA types. Understanding these distinctions helps in selecting the appropriate battery for applications requiring reliability and low maintenance.

Overview of SLA (Sealed Lead Acid) Batteries

SLA (Sealed Lead Acid) batteries are a type of rechargeable battery known for their maintenance-free design and spill-proof construction, achieved by immobilizing the electrolyte in a gel or AGM (Absorbent Glass Mat) format. These batteries provide reliable power in applications such as uninterruptible power supplies (UPS), emergency lighting, and telecommunications due to their high energy density and deep discharge capabilities. SLA batteries also feature a robust design with low self-discharge rates, making them suitable for long-term storage and standby applications.

What Is a VRLA (Valve Regulated Lead Acid) Battery?

A VRLA (Valve Regulated Lead Acid) battery is a sealed lead-acid battery designed with a pressure relief valve to prevent gas buildup, enabling maintenance-free operation. It uses a recombinant technology where oxygen produced at the positive plate is chemically absorbed at the negative plate, minimizing water loss and extending battery life. VRLA batteries are commonly used in backup power systems, uninterruptible power supplies (UPS), and renewable energy applications due to their safety and reliability benefits over traditional SLA (Sealed Lead Acid) batteries.

Construction and Design: SLA vs VRLA Batteries

SLA (Sealed Lead Acid) batteries typically feature a robust, leak-proof construction with a sealed casing that prevents electrolyte spillage, utilizing absorbed glass mat (AGM) or gel technology to immobilize the electrolyte. VRLA (Valve Regulated Lead Acid) batteries incorporate a pressure relief valve system, allowing hydrogen gas to recombine internally and maintain a sealed environment, reducing maintenance and extending battery lifespan. Both battery types emphasize safety and durability, but VRLA designs offer enhanced gas management and improved deep-cycle performance through advanced plate and separator materials.

Performance and Efficiency Comparison

SLA (Sealed Lead Acid) batteries typically offer reliable performance with moderate energy density and lower cost, making them suitable for general backup power applications. VRLA (Valve Regulated Lead Acid) batteries, a subset of SLA, enhance efficiency through advanced recombination technology, providing longer cycle life and reduced maintenance by minimizing electrolyte loss. VRLA batteries also exhibit superior deep discharge recovery and better thermal management, resulting in improved overall performance in demanding conditions.

Lifespan and Maintenance Requirements

Sealed Lead Acid (SLA) batteries typically have a lifespan of 3 to 5 years and require minimal maintenance due to their sealed design preventing electrolyte leakage. Valve-Regulated Lead Acid (VRLA) batteries, a subset of SLA, offer similar lifespans but feature advanced valve regulation that reduces gas release and further decreases maintenance needs. Both battery types are preferred in applications demanding reliable power with reduced upkeep, though VRLA batteries often provide enhanced safety and longer service intervals.

Cost Analysis: SLA vs VRLA for Cars

Sealed Lead Acid (SLA) batteries typically offer a lower upfront cost compared to Valve Regulated Lead Acid (VRLA) batteries, making them a budget-friendly option for cars. VRLA batteries, although more expensive initially, provide longer lifespan and lower maintenance costs, which can result in better overall value and total cost of ownership. Cost analysis favors SLA for short-term savings, while VRLA is more cost-effective for long-term automotive use due to enhanced durability and performance.

Typical Applications in the Automotive Industry

Sealed Lead Acid (SLA) batteries are commonly used in traditional automotive applications such as engine starting and emergency backup power due to their reliable performance and cost-effectiveness. Valve Regulated Lead Acid (VRLA) batteries are preferred in modern vehicles that require maintenance-free operation and enhanced safety, including electric and hybrid cars where vibration resistance and spill-proof design are critical. Both battery types support automotive electronics, but VRLA technology offers superior longevity and efficiency for advanced automotive energy storage systems.

Safety Features and Environmental Impact

Sealed Lead Acid (SLA) batteries are designed with safety features such as a sealed construction that prevents acid leakage, reducing the risk of spills and exposure to corrosive substances. Valve-Regulated Lead Acid (VRLA) batteries enhance safety by incorporating a pressure relief valve to prevent gas buildup and minimize explosion hazards, making them safer for indoor use. From an environmental impact perspective, VRLA batteries generally produce fewer emissions due to their sealed design, allowing for better containment of hazardous materials, while SLA batteries may pose higher risks if damaged or improperly disposed of, highlighting the importance of proper recycling and handling in both types.

Choosing the Right Battery Type: SLA or VRLA for Your Vehicle

Selecting the right battery type for your vehicle involves understanding key differences between SLA (Sealed Lead Acid) and VRLA (Valve Regulated Lead Acid) batteries. SLA batteries offer affordable maintenance-free power but may have shorter life spans under high-demand conditions, whereas VRLA batteries, including Absorbent Glass Mat (AGM) and Gel variants, provide enhanced durability, spill resistance, and better performance in extreme temperatures. Evaluating factors such as vehicle power requirements, climate conditions, and maintenance preferences ensures optimal battery choice for improved reliability and longevity.

SLA vs VRLA Infographic

cardiffo.com

cardiffo.com