Nickel-Metal Hydride (NiMH) batteries offer higher energy density and are more environmentally friendly compared to Nickel-Cadmium (NiCd) batteries, making them ideal for modern Battery pet devices. NiCd batteries suffer from memory effect and toxic cadmium content, limiting their usability and disposal options. NiMH batteries provide longer battery life and improved performance with less environmental impact, enhancing the overall user experience in Battery pet products.

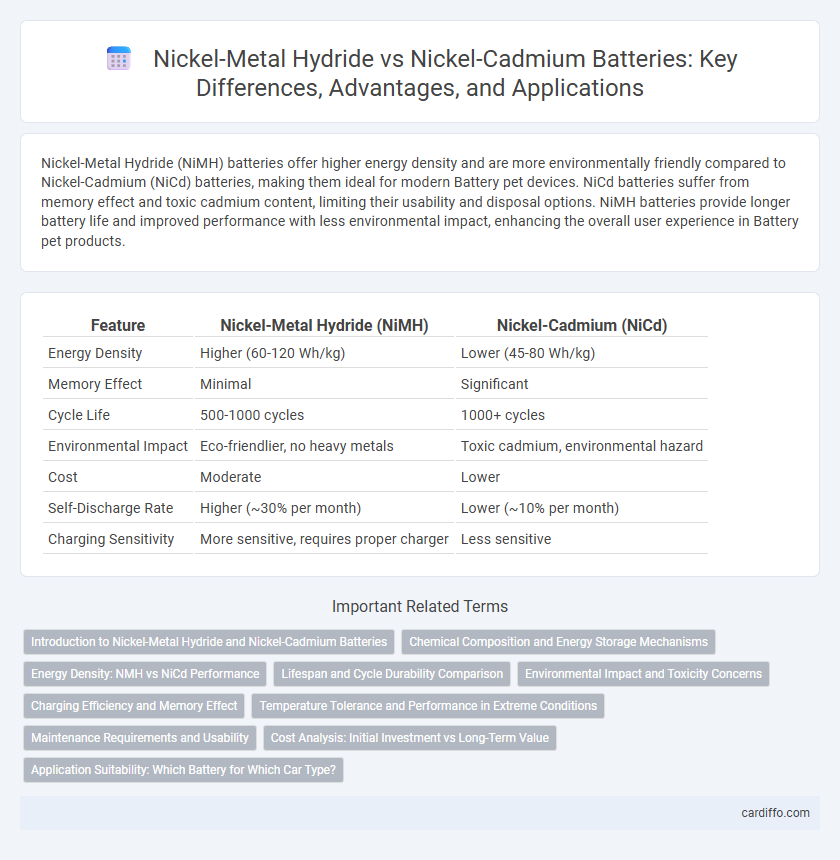

Table of Comparison

| Feature | Nickel-Metal Hydride (NiMH) | Nickel-Cadmium (NiCd) |

|---|---|---|

| Energy Density | Higher (60-120 Wh/kg) | Lower (45-80 Wh/kg) |

| Memory Effect | Minimal | Significant |

| Cycle Life | 500-1000 cycles | 1000+ cycles |

| Environmental Impact | Eco-friendlier, no heavy metals | Toxic cadmium, environmental hazard |

| Cost | Moderate | Lower |

| Self-Discharge Rate | Higher (~30% per month) | Lower (~10% per month) |

| Charging Sensitivity | More sensitive, requires proper charger | Less sensitive |

Introduction to Nickel-Metal Hydride and Nickel-Cadmium Batteries

Nickel-Metal Hydride (NiMH) batteries offer higher energy density and greater environmental friendliness compared to Nickel-Cadmium (NiCd) batteries, which are known for their robust cycle life and resistance to memory effect. NiMH batteries use a hydrogen-absorbing alloy for the negative electrode, while NiCd batteries use cadmium, a toxic heavy metal that raises environmental concerns. Both battery types find applications in portable electronics and hybrid vehicles, with NiMH gaining popularity due to improved capacity and reduced ecological impact.

Chemical Composition and Energy Storage Mechanisms

Nickel-Metal Hydride (NiMH) batteries utilize a hydrogen-absorbing alloy for the anode and nickel oxyhydroxide for the cathode, enabling higher energy density compared to Nickel-Cadmium (NiCd) batteries, which use cadmium for the anode and nickel oxyhydroxide for the cathode. The energy storage mechanism in NiMH involves the reversible absorption and release of hydrogen ions in the metal hydride alloy, while NiCd stores energy through redox reactions between cadmium and nickel hydroxide electrodes. NiMH batteries exhibit improved environmental safety and reduced memory effect due to their non-toxic metal hydride composition and less pronounced crystalline changes during charge-discharge cycles.

Energy Density: NMH vs NiCd Performance

Nickel-Metal Hydride (NiMH) batteries offer significantly higher energy density compared to Nickel-Cadmium (NiCd) batteries, typically ranging from 60 to 120 Wh/kg versus NiCd's 45 to 80 Wh/kg. This enhanced energy density enables NiMH batteries to store more energy within the same weight, making them ideal for applications requiring longer runtime and lighter weight. NiCd batteries, while lower in energy density, excel in durability and performance under extreme temperatures, but their capacity limitations often restrict use in modern high-capacity devices.

Lifespan and Cycle Durability Comparison

Nickel-Metal Hydride (NiMH) batteries typically offer a longer lifespan and higher cycle durability compared to Nickel-Cadmium (NiCd) batteries, often lasting between 500 to 1000 charge cycles versus 300 to 500 cycles for NiCd. NiMH batteries maintain capacity better over time due to lower memory effect and reduced risk of crystallization. The improved cycle durability of NiMH cells makes them more suitable for applications requiring frequent recharging and longer-term reliability.

Environmental Impact and Toxicity Concerns

Nickel-Metal Hydride (NiMH) batteries offer a more environmentally friendly alternative to Nickel-Cadmium (NiCd) batteries due to their reduced toxic heavy metal content, specifically the absence of harmful cadmium. NiCd batteries pose significant ecological risks through cadmium leaching, which contaminates soil and water, leading to long-term toxicity concerns. NiMH batteries are favored in sustainable applications as they mitigate hazardous waste issues and facilitate safer recycling processes.

Charging Efficiency and Memory Effect

Nickel-Metal Hydride (NiMH) batteries offer higher charging efficiency than Nickel-Cadmium (NiCd) batteries, delivering greater energy capacity and faster recharge rates. NiCd batteries are prone to the memory effect, which reduces their effective capacity over time, whereas NiMH cells exhibit significantly less memory effect, maintaining consistent performance through repeated charge cycles. The superior charging efficiency and reduced memory effect make NiMH more suitable for high-drain applications requiring long-term reliability.

Temperature Tolerance and Performance in Extreme Conditions

Nickel-Metal Hydride (NiMH) batteries exhibit superior temperature tolerance compared to Nickel-Cadmium (NiCd) batteries, maintaining optimal performance in a broader temperature range from -20degC to 60degC. NiMH cells demonstrate enhanced energy density and reduced memory effect, enabling better reliability in extreme cold and heat scenarios, critical for applications like electric vehicles and outdoor equipment. NiCd batteries, while robust in low temperatures down to -40degC, suffer from lower capacity and higher environmental toxicity, limiting their efficiency and sustainability under harsh conditions.

Maintenance Requirements and Usability

Nickel-Metal Hydride (NiMH) batteries require less maintenance than Nickel-Cadmium (NiCd) batteries, as they do not suffer from the memory effect as severely, reducing the need for frequent full discharges and recharge cycles. NiMH batteries offer greater usability in modern devices due to higher capacity and environmentally friendly composition, while NiCd batteries often require careful handling and periodic deep discharging to maintain performance. The reduced maintenance needs and improved energy density of NiMH make them more suitable for consumer electronics and renewable energy storage applications.

Cost Analysis: Initial Investment vs Long-Term Value

Nickel-Metal Hydride (NiMH) batteries typically have a higher initial cost compared to Nickel-Cadmium (NiCd) batteries due to advanced materials and manufacturing processes. Over the long term, NiMH batteries offer better value through higher energy density, longer cycle life, and reduced maintenance expenses, leading to greater overall cost efficiency. NiCd batteries suffer from memory effect and environmental disposal costs, which can increase total ownership expenses despite their lower upfront price.

Application Suitability: Which Battery for Which Car Type?

Nickel-Metal Hydride (NiMH) batteries are ideal for hybrid electric vehicles (HEVs) due to their higher energy density and environmental friendliness, making them suitable for passenger cars focused on fuel efficiency and reduced emissions. Nickel-Cadmium (NiCd) batteries, with superior durability and tolerance to extreme temperatures, are often used in commercial vehicles and heavy-duty applications where reliability under harsh conditions is critical. Choosing between NiMH and NiCd batteries depends largely on the specific vehicle type and operational needs, with NiMH favored for everyday consumer hybrids and NiCd preferred in industrial or off-road automotive contexts.

Nickel-Metal Hydride vs Nickel-Cadmium Infographic

cardiffo.com

cardiffo.com