Cylindrical cells offer high durability and efficient heat dissipation due to their shape, making them ideal for applications requiring long cycle life and stability. Prismatic cells provide better space utilization with a compact design, allowing higher energy density in limited volumes, suitable for mobile devices and electric vehicles. The choice between cylindrical and prismatic cells depends on balancing size constraints, thermal management, and manufacturing costs for specific battery-powered applications.

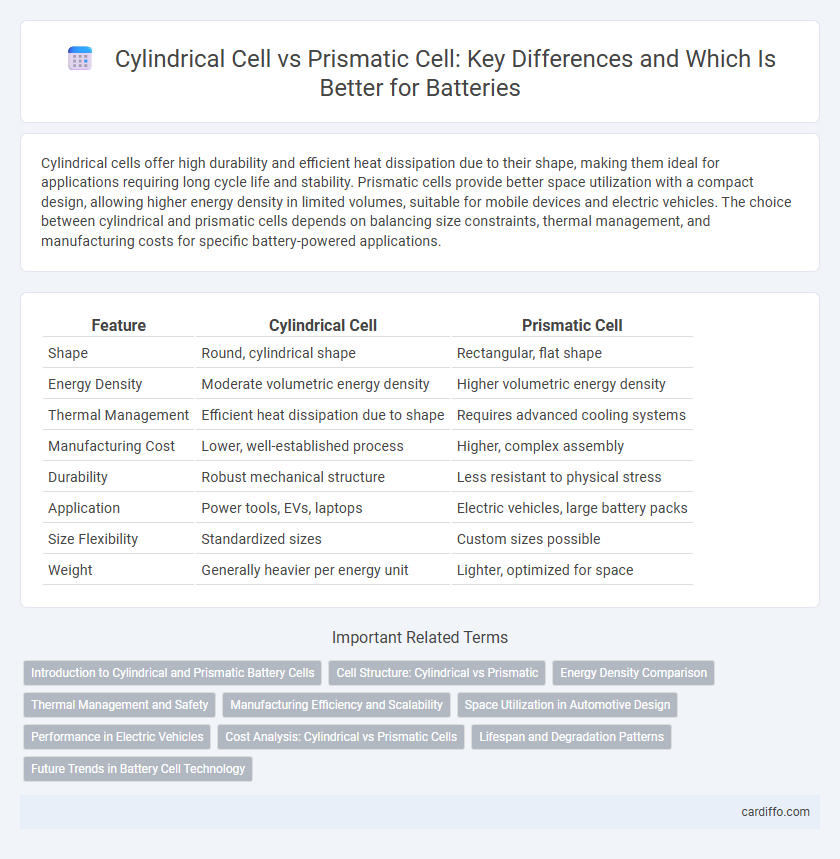

Table of Comparison

| Feature | Cylindrical Cell | Prismatic Cell |

|---|---|---|

| Shape | Round, cylindrical shape | Rectangular, flat shape |

| Energy Density | Moderate volumetric energy density | Higher volumetric energy density |

| Thermal Management | Efficient heat dissipation due to shape | Requires advanced cooling systems |

| Manufacturing Cost | Lower, well-established process | Higher, complex assembly |

| Durability | Robust mechanical structure | Less resistant to physical stress |

| Application | Power tools, EVs, laptops | Electric vehicles, large battery packs |

| Size Flexibility | Standardized sizes | Custom sizes possible |

| Weight | Generally heavier per energy unit | Lighter, optimized for space |

Introduction to Cylindrical and Prismatic Battery Cells

Cylindrical battery cells feature a round, tubular shape that offers robust mechanical stability and efficient thermal management, making them ideal for high-drain applications like electric vehicles and power tools. Prismatic battery cells utilize a rectangular, flat design that enables higher space utilization and flexible pack configurations, commonly used in smartphones, laptops, and electric vehicles. Both cell types employ lithium-ion chemistry but differ significantly in packaging efficiency, cost, and thermal characteristics.

Cell Structure: Cylindrical vs Prismatic

Cylindrical cells feature a spiral-wound electrode design enclosed in a metal can, offering robust structural integrity and efficient heat dissipation. Prismatic cells utilize stacked layers of electrodes within a rectangular casing, enabling higher energy density and better space utilization in battery packs. The cylindrical design enhances mechanical stability, while prismatic cells allow for more flexible form factors and optimized packing in electric vehicles and portable devices.

Energy Density Comparison

Cylindrical cells generally exhibit higher volumetric energy density due to their efficient heat dissipation and structural strength, allowing for more compact electrode stacking. Prismatic cells offer better gravimetric energy density, with a shape that maximizes space utilization in battery packs, especially in automotive applications. The choice between cylindrical and prismatic cells hinges on balancing volumetric efficiency and weight optimization based on specific energy demands.

Thermal Management and Safety

Cylindrical cells offer superior thermal management due to their uniform shape, which allows efficient heat dissipation and reduces the risk of hotspots, enhancing overall battery safety. Prismatic cells, while space-efficient, tend to have less effective thermal conductivity and a higher chance of thermal runaway due to uneven heat distribution within their larger surface area. Effective cooling systems are crucial for prismatic cells to maintain safety standards and prevent overheating during high-demand operation.

Manufacturing Efficiency and Scalability

Cylindrical cells benefit from established automated production lines that enhance manufacturing efficiency through standardized shapes, resulting in lower costs and faster scalability. Prismatic cells, while offering better space utilization in battery packs, face more complex assembly processes that can limit production speed and increase initial manufacturing investment. Scaling cylindrical cell manufacturing is streamlined due to modular designs and higher yield rates, making it preferable for large-scale battery production.

Space Utilization in Automotive Design

Cylindrical cells offer higher mechanical stability and efficient thermal management but often result in lower space utilization due to their round shape, creating gaps within battery packs. Prismatic cells maximize space utilization in automotive design by providing a rectangular form factor that fits seamlessly into designated battery compartments, enhancing overall energy density. Optimizing battery layout with prismatic cells supports compact vehicle designs and maximizes the available volume for energy storage.

Performance in Electric Vehicles

Cylindrical cells offer enhanced thermal management and higher structural integrity, enabling better performance under high discharge rates in electric vehicles. Prismatic cells provide superior space efficiency and energy density, which improves driving range and packaging flexibility. Both cell types impact overall battery pack performance, with cylindrical cells excelling in durability and prismatic cells optimizing vehicle design integration.

Cost Analysis: Cylindrical vs Prismatic Cells

Cylindrical cells typically offer lower production costs due to standardized manufacturing processes and widespread supplier networks, making them cost-efficient for large-scale applications. Prismatic cells require more complex assembly and materials, often resulting in higher initial production expenses but providing better space utilization and energy density. The overall cost-effectiveness depends on the application, with cylindrical cells favored for mass-produced consumer electronics and prismatic cells preferred in automotive or stationary energy storage where form factor and performance justify the expense.

Lifespan and Degradation Patterns

Cylindrical cells typically exhibit longer lifespans due to their robust mechanical structure that evenly distributes stress, reducing degradation over time. Prismatic cells, while offering higher energy density, often experience faster capacity loss caused by uneven electrode expansion and contraction during charge cycles. Optimal battery management systems can mitigate degradation patterns in both cell types, extending their effective service life.

Future Trends in Battery Cell Technology

Future trends in battery cell technology emphasize the development of high-energy-density cylindrical cells and space-efficient prismatic cells, driven by advancements in materials like silicon anodes and solid-state electrolytes. Innovations in manufacturing techniques, such as automated stacking and laser welding, enhance production scalability and cell reliability for electric vehicles and grid storage. The shift towards sustainable and recyclable cell designs is accelerating, reflecting the growing demand for eco-friendly battery solutions in renewable energy integration.

Cylindrical Cell vs Prismatic Cell Infographic

cardiffo.com

cardiffo.com