Parallel wiring in battery packs maintains the voltage of a single cell while increasing overall capacity by combining multiple cells side by side, enhancing runtime without boosting voltage. Series wiring connects cells end-to-end, summing their voltages to achieve higher power output required for demanding devices, but capacity remains equal to a single cell. Choosing between parallel and series wiring depends on the specific voltage and capacity needs of the application, balancing power delivery with battery life.

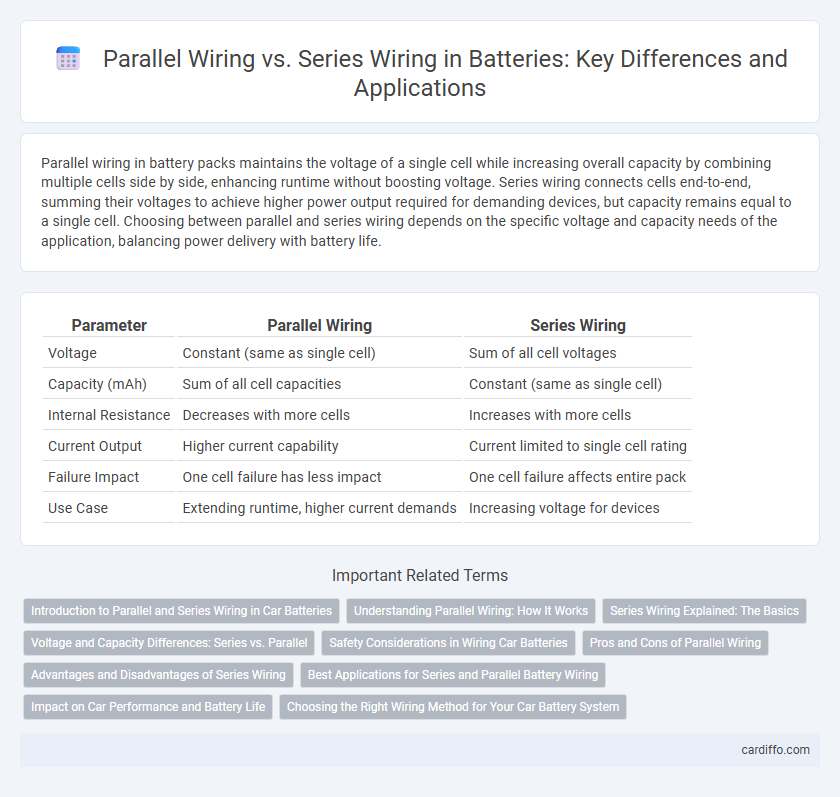

Table of Comparison

| Parameter | Parallel Wiring | Series Wiring |

|---|---|---|

| Voltage | Constant (same as single cell) | Sum of all cell voltages |

| Capacity (mAh) | Sum of all cell capacities | Constant (same as single cell) |

| Internal Resistance | Decreases with more cells | Increases with more cells |

| Current Output | Higher current capability | Current limited to single cell rating |

| Failure Impact | One cell failure has less impact | One cell failure affects entire pack |

| Use Case | Extending runtime, higher current demands | Increasing voltage for devices |

Introduction to Parallel and Series Wiring in Car Batteries

Parallel wiring in car batteries connects multiple batteries positive to positive and negative to negative, increasing overall capacity (amp-hours) while maintaining the same voltage as a single battery. Series wiring links batteries positive to negative, combining their voltages while keeping the amp-hour capacity equivalent to one battery. Understanding the differences between parallel and series wiring is crucial for optimizing battery performance and meeting specific voltage and capacity requirements in automotive applications.

Understanding Parallel Wiring: How It Works

Parallel wiring connects battery cells side-by-side, maintaining the same voltage across all cells while increasing total capacity (ampere-hours). Each cell's positive terminal is linked to the positive terminal of others, and similarly for negatives, allowing current to flow independently through each path. This configuration enhances overall current output and extends battery runtime without increasing voltage.

Series Wiring Explained: The Basics

Series wiring connects battery cells end-to-end, increasing the total voltage while maintaining the same capacity (ampere-hours). Each cell's positive terminal links to the next cell's negative terminal, resulting in a cumulative voltage equal to the sum of all individual cell voltages. This configuration is ideal for applications requiring higher voltage output, such as electric vehicles and power tools.

Voltage and Capacity Differences: Series vs. Parallel

In series wiring, battery voltages add up while the capacity remains the same as a single cell, resulting in higher voltage and unchanged amp-hour (Ah) rating. Parallel wiring maintains the voltage of a single battery but increases overall capacity by summing the amp-hour ratings of all connected batteries. Choosing between series and parallel configurations depends on whether the application requires higher voltage or increased capacity for longer runtime.

Safety Considerations in Wiring Car Batteries

Parallel wiring in car batteries maintains the voltage while increasing capacity, reducing the risk of overvoltage and overheating by distributing the load evenly across cells. Series wiring increases voltage but demands careful matching of battery capacity and condition to prevent imbalance, which can cause cell damage or thermal runaway. Proper fusing, secure cable connections, and regular maintenance are critical in both configurations to ensure safe operation and prevent electrical hazards.

Pros and Cons of Parallel Wiring

Parallel wiring in battery configurations offers the significant benefit of increased current capacity and extended runtime by maintaining the voltage level constant while combining the ampere-hours of each cell. This setup provides greater reliability since individual battery failures typically do not disrupt the entire system, allowing easier replacement and enhanced safety. However, the downside includes the risk of imbalanced charging and discharging, which can reduce overall battery lifespan and necessitates careful management with protective circuitry to prevent overheating and overcurrent conditions.

Advantages and Disadvantages of Series Wiring

Series wiring in batteries increases total voltage by summing individual cell voltages, enhancing power output for high-voltage applications. However, its disadvantages include reduced overall capacity, as the current remains limited to the weakest cell, and a single cell failure can disrupt the entire circuit. This wiring configuration is suitable for devices requiring higher voltage but less optimal for those prioritizing longer battery life or reliability.

Best Applications for Series and Parallel Battery Wiring

Series battery wiring is ideal for applications requiring higher voltage outputs, such as electric vehicles and power tools, where battery cells are connected end-to-end to increase total voltage while maintaining the same capacity. Parallel battery wiring suits situations demanding extended runtime and greater capacity, like in solar power storage systems or uninterruptible power supplies (UPS), by connecting all positive terminals together and all negative terminals together to increase current capacity without changing voltage. Selecting between series and parallel depends on the voltage and capacity needs specific to devices or systems.

Impact on Car Performance and Battery Life

Parallel wiring in car batteries maintains a consistent voltage while increasing overall capacity, enhancing cranking power and extending battery life by reducing strain during engine starts. Series wiring increases voltage output, which boosts engine performance but can accelerate battery degradation due to higher stress and heat generation. Choosing the right configuration balances improved car performance and optimal battery lifespan based on specific vehicle power demands and usage patterns.

Choosing the Right Wiring Method for Your Car Battery System

Choosing the right wiring method for your car battery system depends on the desired voltage and capacity. Parallel wiring increases amp-hour capacity while maintaining the same voltage, ideal for longer-lasting power supply needs. Series wiring increases voltage by adding the voltage of each battery, which is essential for higher voltage requirements but does not extend run time.

Parallel Wiring vs Series Wiring Infographic

cardiffo.com

cardiffo.com